To create solar energy, a variety of materials are essential, including 1. Silicon, 2. Conductors, 3. Encapsulants, 4. Backing materials, 5. Inverters, and 6. Mounting structures. Among these, silicon plays a pivotal role, being the primary material used in the majority of solar photovoltaic (PV) cells due to its excellent semiconductor properties. Silicon is derived from silica, which is abundantly found in sand. The extraction and refinement processes for silicon are critical as they determine the efficiency and cost of solar panels. High-purity silicon is needed to create solar cells that convert sunlight into electricity efficiently. In addition to silicon, various conductive materials, including copper and aluminum, are indispensable for forming the electrical connections that allow electricity to flow from the solar cells to the inverter and ultimately to the power grid. Capturing and utilizing solar energy successfully therefore hinges on the interplay of these materials and their properties.

1. SILICON: THE CORE MATERIAL

Silicon has emerged as the foundation for contemporary solar panel technology. Its semiconductor characteristics enable the efficient conversion of sunlight into electricity. Silicon exists in different forms, primarily monocrystalline, polycrystalline, and amorphous, each having distinct structural properties and efficiency levels.

Monocrystalline silicon, made from a single crystal structure, boasts the highest efficiency rates, often exceeding 22%. These panels occupy less space compared to other types while producing optimal energy. Conversely, polycrystalline silicon is composed of multiple crystal structures and typically offers lower efficiency, around 15-20%. Despite this, polycrystalline panels carry a lower price point, making them appealing for homeowners seeking budget-friendly options.

Amorphous silicon, a non-crystalline variant, offers flexibility and lightweight properties, thus suitable for specific applications like building-integrated photovoltaics (BIPV). While it’s less efficient compared to crystalline counterparts, its usage is integral for novel solar technology deployments.

2. CONDUCTIVE MATERIALS

As crucial as silicon, conductive materials facilitate the transfer of generated electricity from solar cells to the storage units or grid systems. The most commonly used conductive materials include copper and aluminum. Copper stands out as an exceptional conductor of electricity due to its high conductivity and reliability, ensuring low energy loss during transmission.

Solar panels require a grid-like network of conductive paths, typically created with copper wires. These wires collect and transfer electrons generated from the silicon cells efficiently. While copper is the primary conductor, aluminum is often utilized for the frame and backing material of solar panels owing to its lightweight nature and resistance to corrosion, increasing the panel’s longevity and performance.

The choice of conductive materials can significantly influence the overall efficiency and cost-effectiveness of solar energy systems. Hence, manufacturers frequently evaluate these materials to optimize performance while minimizing expenses.

3. ENCAPSULANTS AND BACKING MATERIALS

To ensure durability and maximize the lifespan of solar panels, encapsulants and backing materials play pivotal roles. Encapsulants are generally made from ethylene-vinyl acetate (EVA), a substance that secures the solar cells within the glass and protects them from moisture, dirt, and other environmental factors.

A high-quality encapsulant maintains transparency and adhesion over time, ensuring that sunlight can reach the solar cells without interference and that the panels remain intact under varying conditions. This shielding is vital because degradation from external elements can significantly diminish a panel’s efficiency.

Backing materials, often composed of polymers or composite materials, provide further protection to the solar cells. They must be durable and resistant to UV radiation, temperature fluctuations, and moisture. A solid backing material serves not only to shield the panel’s internal components but also influences the overall efficiency and performance of the solar power system.

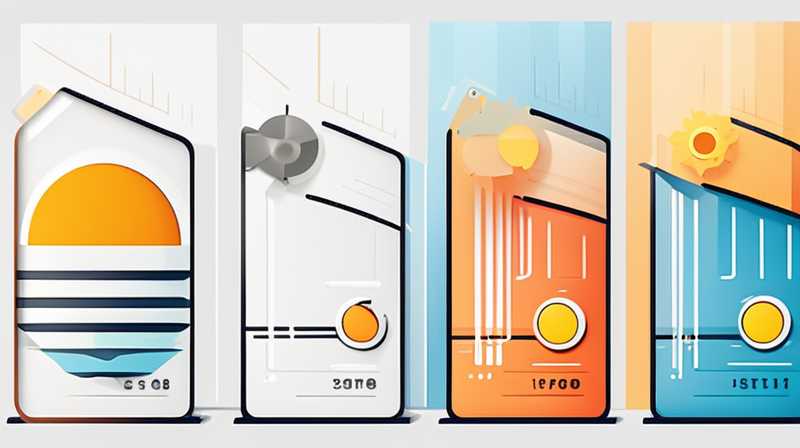

4. INVERTERS: CONVERTING DC TO AC

In solar energy systems, inverters serve an indispensable purpose by converting direct current (DC), generated by the solar panels, into alternating current (AC), which is utilized by household appliances and the electrical grid. This conversion process is crucial since most electrical devices operate on AC current.

Several types of inverters exist, including string inverters, microinverters, and power optimizers. String inverters are commonly used in residential solar energy systems due to their cost-effectiveness and simplicity. They work by connecting multiple solar panels into a “string” and centralized their conversion process.

Microinverters, in contrast, are attached individually to each solar panel, allowing for optimized performance and efficiency regardless of shading or orientation. Though typically more expensive, they can yield additional electricity, justifying their cost in specific scenarios.

The selection of the inverter significantly influences the efficiency and performance of the entire solar energy system, making it crucial to align the inverter type with individual energy needs and installation conditions.

5. MOUNTING STRUCTURES

Mounting structures are necessary for securing solar panels to roofs or the ground, forming a robust and stable base. The choice of mounting materials directly impacts the system’s longevity, performance, and maintenance requirements. Common materials used for mounting systems include aluminum and galvanized steel.

Aluminum is favored for its lightweight properties and resistance to corrosion, facilitating easy installation while ensuring minimal weight load on roofs. Galvanized steel, known for its strength and durability, is often chosen for ground-mounted systems to withstand extreme weather conditions.

The design of the mounting structure also plays a crucial role in optimizing the angle and orientation of solar panels for maximum sunlight exposure. Proper installation not only enhances energy production but also prevents physical damage to the panels during adverse weather conditions.

FREQUENTLY ASKED QUESTIONS

WHAT IS THE ROLE OF SILICON IN SOLAR PANELS?

Silicon serves as the foundational material in solar panels, primarily in photovoltaic (PV) cells, where it acts as a semiconductor to convert sunlight into electricity. It exists in several forms, including monocrystalline, polycrystalline, and amorphous silicon. Each variant offers different efficiency levels, with monocrystalline being the most efficient, allowing for more electricity generation in less space. Furthermore, silicon’s cost-effectiveness and availability make it a favorable choice for solar energy production. The solar energy industry heavily invests in improving silicon manufacturing processes to boost efficiency and lower costs, ensuring that solar technology remains competitive with other energy sources.

HOW DO INVERTERS WORK IN SOLAR ENERGY SYSTEMS?

Inverters play a vital role in solar energy systems by transforming the direct current (DC) generated by solar panels into alternating current (AC), which can be utilized by home appliances and integrated into the power grid. There are various types of inverters available, including string inverters, microinverters, and power optimizers. Each inverter type offers unique advantages, depending on specific system needs and installation conditions. For instance, microinverters can maximize energy production by optimizing performance for individual panels, while string inverters are typically more cost-effective for simpler installations. The efficiency and performance of a solar energy system heavily hinge on the inverter’s effectiveness, making its selection crucial in system planning.

WHAT OTHER MATERIALS ARE ESSENTIAL FOR SOLAR PANEL MANUFACTURE?

In addition to silicon and conductive materials, there are several other components necessary for solar panel manufacturing. Encapsulants like ethylene-vinyl acetate (EVA) protect solar cells from environmental factors while maintaining transparency for optimal sunlight passage. The backing material also contributes significantly, providing structural integrity and shielding against moisture and UV radiation to enhance the panel’s longevity. Lastly, mounting structures crafted from aluminum or galvanized steel securely anchor solar panels, ensuring their stability and performance over time. Each material contributes uniquely to the overall efficacy and durability of solar energy systems, marking them crucial for optimal energy production.

The necessity for fundamental materials in solar energy generation highlights the intricate relationship between technology and sustainability. As the world embraces renewable energy to combat climate change, enhancing the efficiency and sustainability of these materials becomes paramount. Innovations in silicon production, along with advancements in conductive, encapsulating, and backing materials, continue to evolve. This dynamic landscape adapts to shifting energy demands, while ongoing research into alternative materials complements traditional choices, potentially leading to breakthroughs in solar panel technology.

Given the role of inverters in converting electricity, manufacturers seek to enhance their efficiency and compatibility with an array of solar cells and installations, all while prioritizing affordability and accessibility for consumers. Lastly, the selection and design of mounting structures are key factors in maximizing sunlight exposure, ensuring stable installations throughout varying environmental conditions.

With the global push towards green energy solutions, the interplay between these materials and technologies carries significant implications for future energy strategies. Adopting solar energy systems not only expands access to renewable energy sources but also drives economic growth through job creation in manufacturing, installation, and maintenance sectors. Continuing to innovate and invest in solar technology will be crucial as the world transitions to more sustainable energy practices.

As the pursuit of climate-conscious solutions intensifies, it is evident that understanding and enhancing the materials utilized for solar energy will be integral in making sustainable energy options both viable and widespread. This awareness is essential for stakeholders, policymakers, and individuals alike as they navigate towards a greener future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-materials-are-needed-to-make-solar-energy-2/