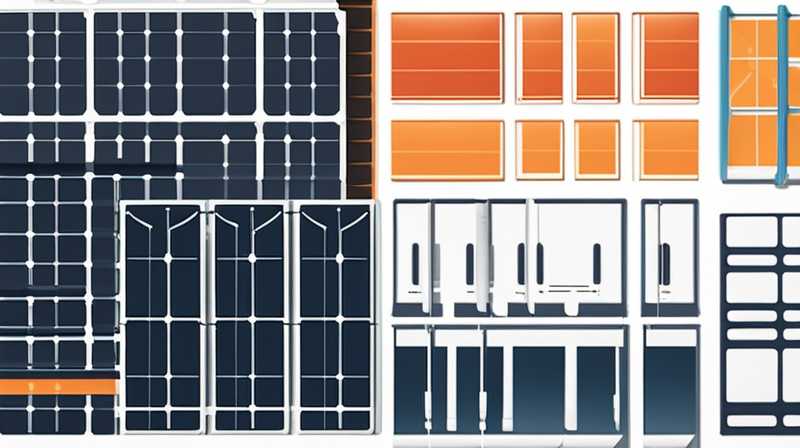

To assemble solar photovoltaic panels, several materials are required: 1. Silicon cells, 2. Conductive metals, 3. Glass, 4. Frame materials, 5. Backing materials. Silicon cells are the heart of the panel, responsible for converting sunlight into electricity, while conductive metals facilitate the effective flow of electricity generated. Glass provides protection against environmental conditions while allowing optimal light transmission. Frame materials add structural support and durability, and backing materials ensure insulation and protection for internal components. Together, these components create a functional and efficient solar panel system that harnesses solar energy effectively.

1. SILICON CELLS

Silicon serves as the primary photovoltaic material used in solar panels. The two types of silicon utilized are monocrystalline and polycrystalline, each offering distinct advantages. Monocrystalline silicon is recognized for its higher efficiency and longevity, often associated with a more compact design. This form is produced from a single crystal lattice, facilitating the flow of electrons and resulting in better performance under low light conditions. In contrast, polycrystalline silicon is created from multiple silicon crystals melted together, making it a more cost-effective option but with slightly lower efficiency.

The selection of silicon cells significantly impacts the overall effectiveness of photovoltaic systems. For instance, monocrystalline panels often yield 15-20% more electricity than their polycrystalline counterparts, making them ideal for limited spaces. Furthermore, advancements in silicon technology, such as Bifacial solar cells, have emerged. These cells harness sunlight from both sides, maximizing energy output, especially in snowy or reflective environments. Understanding the nuances between these materials is crucial for selecting the appropriate solar technology for specific applications.

2. CONDUCTIVE METALS

For photovoltaic panels to function efficiently, the integration of conductive metals is crucial. Copper and aluminum are the primary metals employed for their superior conductive properties. Copper acts as the primary conductor, facilitating the flow of electricity from the silicon cells to the inverter and ultimately to the electrical grid or storage system. Its high conductivity ensures minimal energy loss during transmission, reinforcing efficiency in energy conversion.

Aluminum serves as a robust alternative, especially in structural components of solar panels. Its lightweight nature and resistance to corrosion make it an ideal choice for framing and supporting mechanisms. Additionally, aluminum is utilized in interconnection wiring that links multiple solar cells together within a module. Ensuring that these conductive metals are of high quality is essential, as impurities can lead to overheating and diminish solar panel performance.

3. GLASS

The protective layer of solar panels is primarily composed of glass. This material is specifically designed to be highly transparent to maximize light penetration while ensuring durability against various climatic conditions. Low-iron glass is commonly used, which allows for higher light transmission compared to regular glass due to its reduced impurity levels. This enhances the panel’s ability to capture sunlight efficiently.

In addition to light transmission, the glass used in solar panels must be resilient and able to withstand environmental stressors such as hail, wind, and rain. Tempered glass is often employed, as it is approximately five times stronger than standard glass and greatly reduces the risk of breakage. Furthermore, self-cleaning coatings are now available to help maintain panel efficiency by minimizing dust accumulation, which can obstruct sunlight. The combination of strength and transparency in the glass ensures solar panels remain effective over their lifespan.

4. FRAME MATERIALS

Frameworks provide necessary structural integrity to solar panels. Most commonly, aluminum frames are utilized due to their lightweight characteristics and resistance to corrosion. Such properties are essential for outdoor installations, where exposure to potential environmental damage is prevalent. Aluminum frames can support the weight of the solar panel while facilitating easy installation and maintenance.

Moreover, the design of the frame plays a crucial role in the panel’s performance. A well-engineered frame allows for thermal expansion and contraction, thereby minimizing stress on the panel during temperature fluctuations. Specialized mounting systems that accompany these frames can also improve wind resistance and overall stability. Efficient engineering of frame materials also includes considerations for aesthetics and alignment, ensuring that solar panels are not only functional but also visually appealing within their installation environment.

5. BACKING MATERIALS

Backing materials serve as the protective layer behind solar cells, insuring them against environmental hazards such as moisture, dirt, and temperature variances. Ethylene vinyl acetate (EVA) is a common choice, providing encapsulation for the silicon cells. EVA is known for its excellent transparency and durability, ensuring that the solar cells are securely held in place while allowing maximum light exposure.

Additionally, the integrity of backing materials affects the longevity of solar panels. Water ingress and potential rot can severely diminish a system’s efficiency. Thus, advanced materials like polyester or Tedlar are incorporated for their excellent moisture barriers, significantly enhancing the durability of solar panels. These backing materials must adhere to strict standards to ensure they can withstand years of environmental exposure while maintaining performance.

6. INVERTER COMPONENTS

The inverter plays an integral role in converting the direct current (DC) generated by solar panels into alternating current (AC), which is what is typically used in homes and on the grid. String inverters are commonly used, where multiple panels are connected in series, allowing for efficient energy conversion, while microinverters are utilized on a per-panel basis, providing advantages in shaded or complex installations.

The choice of inverter materials reflects the advancements in technology that contribute to improved efficiency and longevity. Modern inverters often incorporate durable components that can withstand outdoor elements, including heat and moisture. Integration with smart technology enables monitoring and management of energy production, further enhancing the overall efficiency of solar power systems.

FREQUENTLY ASKED QUESTIONS

WHAT IS THE ROLE OF SILICON IN SOLAR PANELS?

Silicon serves as the fundamental material that converts sunlight into electrical energy within solar panels. The most common forms of silicon used are monocrystalline and polycrystalline. Monocrystalline silicon features a higher efficiency rate, allowing for better performance under low-light conditions due to its single crystalline structure. This may make it suitable for installations where space is limited. Conversely, polycrystalline silicon is made from multiple silicon crystals, generally offering lower efficiency but at a lower cost, which can be beneficial for larger installations where budget constraints are a factor. Both types of silicon have advantages that will impact the overall effectiveness of a solar photovoltaic system, thus making it essential to consider various factors such as space, budget, and expected energy yield when choosing the appropriate type for specific solar applications.

HOW DOES THE CHOICE OF GLASS AFFECT SOLAR PANEL PERFORMANCE?

The choice of glass significantly impacts solar panel performance by influencing light transmission and durability. Low-iron glass is often utilized due to its superior transparency, allowing for maximum sunlight exposure and thereby increasing efficiency. Regular glass may block some light due to impurities, which in turn could limit the overall yield of energy. Additionally, the strength and resilience of glass affect a panel’s ability to withstand environmental factors such as hail and wind. Tempered glass is preferred for its enhanced strength, ensuring longevity in outdoor applications. With the integration of self-cleaning coatings, maintenance of glass cleanliness is also facilitated, further contributing to sustained performance. Therefore, selecting high-quality glass ensures both the efficiency and durability of solar panels.

WHAT MATERIALS ARE COMMONLY USED IN SOLAR INVERTERS?

Solar inverters are composed of various materials that contribute to their efficiency and longevity. Key components include advanced semiconductor materials, such as silicon and gallium nitride, which are essential for energy conversion processes. Additionally, durable metallic materials like aluminum are commonly used for casings, enhancing protection against environmental conditions. Capacitors and inductors are also critical within inverters, where high-quality materials are necessary to handle the electrical stresses encountered during operation. Furthermore, modern inverters often feature smart technology integration, necessitating the use of advanced circuit boards and software. Ultimately, the choice of materials in solar inverters directly impacts their performance, reliability, and efficiency in converting and managing solar energy.

The fundamental materials for solar photovoltaic panels include a range of components, each contributing significantly to system functionality and efficiency. The integration of high-quality silicon cells at the heart of each panel allows for optimal conversion of sunlight into electricity. Conductive metals, particularly copper and aluminum, facilitate effective energy flow, ensuring minimal losses. Glass known for its durability and transparency acts as a protective shield while maximizing light entry. Frame materials, predominantly aluminum, provide essential support and resilience in outdoor settings, enabling panels to withstand environmental challenges. Backing materials like ethylene vinyl acetate enhance protection for solar cells, preventing degradation over time. The effective functioning of solar systems also hinges on the inverter components, ensuring that generated energy is adequately converted and utilized. While considering the selection of solar panels, it is crucial to acknowledge the significance of these materials in contributing to the overall efficiency and performance of solar energy systems. As global reliance on renewable energy continues to grow, understanding the intricacies of such components will become increasingly relevant in optimizing solar technology for sustainable power generation. By carefully evaluating each material’s role and characteristics, consumers and installers can make informed decisions that enhance the longevity and productivity of solar photovoltaic installations. Proper awareness of the materials necessitates a holistic approach to adopting solar power solutions effectively, ensuring maximum returns on investment and contributing to a greener, sustainable future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-materials-are-needed-for-solar-photovoltaic-panels/