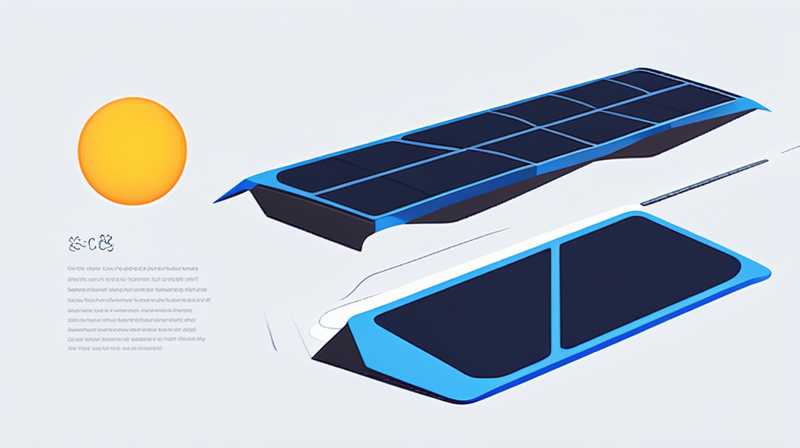

Blue solar panels are typically composed of 1. silicon, 2. anti-reflective coatings, 3. back sheets, and 4. aluminum frames. Silicon is the primary element used in photovoltaic cells, which convert sunlight into electricity. Its crystalline structure is essential for the efficient absorption of solar energy. In detail, silicon exists in either monocrystalline or polycrystalline forms, with the former generally offering higher efficiency and performance under varying light conditions. Anti-reflective coatings are applied to reduce light reflection, allowing more sunlight to penetrate the cells. This layer optimizes energy conversion and boosts overall efficiency. Back sheets provide insulation and support to the solar cells, protecting them from environmental effects, while aluminum frames are used for structural integrity. These components work synergistically to ensure durability and sustained performance in diverse weather conditions.

MATERIAL COMPOSITION OF BLUE SOLAR PANELS

1. SILICON

Silicon serves as the fundamental building block in the majority of blue solar panels. This element forms the core of the photovoltaic cells, where it performs its crucial role in converting solar energy into usable electrical energy. In the solar industry, two primary forms of silicon are prevalent: monocrystalline and polycrystalline. Each type has its unique characteristics and efficiencies.

Monocrystalline silicon is produced from single crystals and is renowned for its high efficiency and space efficiency. This type of silicon solar panel is more efficient in low-light conditions and has a longer lifespan. The manufacturing process of monocrystalline cells involves a technique called the Czochralski process, which provides them with a uniform structure and makes them aesthetically appealing. The efficiency of these panels can reach above 20%, which makes them a preferred choice for residential and commercial applications where space is limited.

Conversely, polycrystalline silicon consists of multiple crystal structures, which gives it a distinct blue hue. While these panels tend to be less efficient than their monocrystalline counterparts, they are generally more cost-effective. The manufacturing process is simpler and less energy-intensive, making polycrystalline panels a popular choice for large-scale solar farms. Typically, the efficiency of polycrystalline panels ranges between 15% to 17%. Understanding the differences between these two forms of silicon is fundamental for consumers and businesses aiming to invest wisely in solar technology.

2. ANTI-REFLECTIVE COATINGS

To maximize the absorption of sunlight, blue solar panels are enhanced with anti-reflective coatings. These coatings play a pivotal role in improving the light-harvesting capabilities of solar cells. Without such layers, a significant amount of sunlight would be reflected away, reducing overall efficiency.

Anti-reflective coatings are made from materials such as silicon nitride and titanium dioxide. The principle behind these coatings involves altering the refractive index between the air and the silicon solar cell surface. By doing so, the panels can capture more sunlight while minimizing glare. A well-implemented anti-reflective coating can improve light absorption by approximately 4-6%, significantly boosting the power output of solar panels.

The technology used in these coatings also needs to accommodate various environmental factors, including dust, rain, and extreme weather conditions. As such, multi-layer coatings have become more prevalent, offering enhanced durability without compromising efficiency. Continuous research is being conducted to develop advanced coatings that can adapt to changing environmental conditions. This ensures that solar panels maintain high performance over their operational lifespan.

3. BACK SHEETS

Another critical component in the construction of blue solar panels is the back sheet. This part provides insulation and safeguards the solar cells from external environmental elements, such as moisture and temperature fluctuations. Back sheets are crucial for overall panel durability and longevity.

Typically, back sheets are made from materials like polyvinyl fluoride (PVF), polyethylene terephthalate (PET), or fluoropolymer. Each material offers distinct properties in terms of weather resistance and thermal expansion. Proper insulation is essential for preventing electrical hazards that can arise due to moisture ingress, which can lead to significant damage or failure of the solar cells.

Furthermore, modern back sheets are designed with optimal thermal management properties. They help dissipate heat generated during the solar panel’s operation, which is crucial for maintaining efficiency. By ensuring that solar panels remain within optimal operating temperatures, back sheets contribute to the overall performance and lifespan of the system. Thus, it is evident that the choice of backsheet material can significantly influence the effectiveness of solar energy systems.

4. ALUMINUM FRAMES

Completing the structural integrity of blue solar panels are aluminum frames. These frames provide necessary support, ensuring that the solar panels stay intact and functional over time. Aluminum is favored due to its lightweight nature, durability, and resistance to corrosion, making it an ideal material for outdoor applications.

Aluminum frames come in various shapes and sizes, depending on the manufacturer and specific requirements of the solar installation. The design of these frames is crucial, as they must withstand adverse weather conditions, from high winds to heavy snowfall. The strength of the frame not only supports the panel itself but also aids in securing it to mounting systems, allowing for proper angling towards the sun.

In addition to structural support, aluminum frames are designed for easy installation and maintenance. They often come with pre-drilled holes that facilitate effortless mounting onto rooftops or supports. Furthermore, many modern aluminum frames also include features that allow for easy removal and replacement of solar panels. As the demand for solar energy continues to rise, the efficiency and versatility of aluminum frames play an essential role in optimizing overall energy production.

FAQ

WHAT IS THE DIFFERENCE BETWEEN MONOCRYSTALLINE AND POLYCRYSTALLINE SOLAR PANELS?

Monocrystalline and polycrystalline solar panels differ primarily in their manufacturing processes and the resulting efficiencies of each type. Monocrystalline panels, made from single silicon crystals, are known for their high efficiency levels, typically exceeding 20%. The uniform structure of these cells allows for better light absorption and performance in low-light conditions. They tend to occupy less space due to their higher efficiency, making them ideal for residential areas where roof space may be limited.

Polycrystalline panels, on the other hand, are made from multiple silicon crystals, leading to a distinct blue appearance. While they are generally less efficient at around 15-17%, they are also more cost-effective. The manufacturing process for polycrystalline panels is simpler, which attracts budget-conscious consumers. While choosing between the two types, considerations such as space, budget, and desired efficiency play a crucial role in making an informed decision. Both types have their advantages and disadvantages, and advancements continue to be made in both technologies.

ARE BLUE SOLAR PANELS BETTER THAN BLACK SOLAR PANELS?

The distinction between blue and black solar panels typically comes down to aesthetics and performance characteristics. Blue solar panels, primarily polycrystalline, tend to have lower efficiency levels compared to black solar panels. Black panels are usually monocrystalline, which not only makes them more efficient but also gives them a sleeker, more modern appearance.

However, the choice between blue and black solar panels involves several factors, including specific energy needs, roof space, and budget. Blue panels often offer a cost advantage due to their simpler manufacturing process. Many homeowners opt for blue solar panels for their economic benefits, while those looking for maximum efficiency might prefer black monocrystalline panels.

It is also worth considering regional environmental factors, such as the amount of sunlight received. In certain situations, the efficiency of black panels in low-light conditions may provide a significant advantage. Ultimately, the decision should be based on personal preferences, financial considerations, and the specific energy goals of the household or business.

HOW LONG DO BLUE SOLAR PANELS LAST?

The lifespan of blue solar panels can range significantly based on several factors, including the materials used, quality of installation, and environmental conditions. Typically, most blue solar panels are designed to last around 25 to 30 years, with manufacturers usually providing warranties that cover performance and integrity over this time frame.

The durability of the panels lies in their ability to withstand various weather conditions, from harsh sunlight to heavy rainfall. However, factors such as extreme temperatures, hail, and storm damage can affect their longevity. Regular maintenance, including cleaning and inspection, can significantly extend the life of solar panels by ensuring that they operate efficiently.

It is also essential to consider technological advancements. Newer models of solar panels often come with improved materials and designs, increasing their resilience and efficiency. As solar technology continues to evolve, investing in high-quality solar panels, whether blue or black, can yield a more substantial long-term return on investment. Reliable manufacturers will provide detailed information regarding the expected lifespan and performance guarantees, allowing consumers to make informed decisions.

In summary, blue solar panels are predominantly crafted from materials including silicon, anti-reflective coatings, back sheets, and aluminum frames. Each component contributes significantly to the panel’s energy conversion capabilities and durability. The choice between competing technologies—such as monocrystalline and polycrystalline—affects efficiency and aesthetic appeal, making careful consideration essential. By understanding the composition and the pros and cons of different solar panel types, consumers can make informed decisions that align with their energy needs and financial constraints. Furthermore, advancements in solar technology continue to improve the functionality and longevity of these panels, making solar energy an increasingly viable option in the renewable energy landscape. Exploring innovations in materials and designs can lead to even greater efficiencies and lower costs, further enhancing the appeal of solar energy across various markets.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-material-are-blue-solar-panels-made-of/