1. Logistics associated with solar panels encompass supply chain management, transportation requirements, and installation processes. The supply chain involves managing the flow of materials, from the manufacturer to the end-user, ensuring that all components arrive at the right place and time. Transportation needs are substantial, as solar panels are bulky and fragile, requiring specialized shipping solutions. Proper installation logistics involve coordinating skilled labor, permits, and equipment, making sure that the deployment is as efficient as possible. Understanding these elements is crucial for effective solar panel commercialization.

1. SUPPLY CHAIN MANAGEMENT

A robust supply chain is fundamental for the successful deployment of solar panels. The process begins with the sourcing of raw materials such as silicon, metals, and glass, which are critical for manufacturing solar cells. The extraction and processing of these materials have substantial environmental implications, necessitating sustainable practices and transparent sourcing policies. Manufacturers must collaborate with suppliers who adhere to ethical practices and can consistently deliver high-quality materials.

The relationship between manufacturers and logistics providers is vital in creating a seamless process. This relationship ensures that the materials needed for production are available when required, thereby avoiding delays that could impact the production schedule. Inventory management also plays a significant role, as excess inventory can incur holding costs, while insufficient stock can lead to suboptimal production levels. Hence, maintaining a careful balance is crucial for operational efficiency.

2. TRANSPORTATION REQUIREMENTS

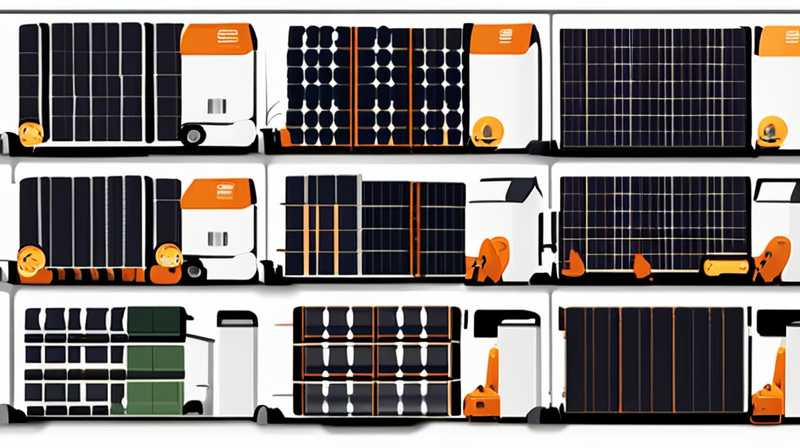

The transportation aspect of solar panel logistics presents unique challenges. Solar panels are typically large and fragile, making them difficult to transport without proper considerations. Specialized packaging and handling protocols are essential to prevent damage during transit. Robust logistics partners are required to navigate the complexities involved in shipping, including the selection of appropriate vehicles and routes that accommodate oversized loads.

Additionally, enabling timely delivery to installation sites involves planning and coordination. Various stakeholders, including manufacturers, logistics providers, and project developers, need to synchronize efforts to ensure that solar panels arrive on-site according to project timelines. Effective communication among these parties is critical for managing potential delays, thereby safeguarding the overall project schedule. Advanced tracking technologies, such as GPS and supply chain management software, are increasingly integrated into transportation logistics to monitor the status of shipments in real-time.

3. INSTALLATION PROCESSES

An efficient installation process is imperative for realizing the benefits of solar technology. Prior to installation, teams must coordinate several logistical components, including obtaining necessary permits and ensuring a skilled workforce is available. Each installation site may have unique challenges, such as varying roof designs or local regulations, that require customized approaches. Pre-installation assessments can help to identify these factors and develop tailored solutions.

Moreover, the presence of various installation techniques necessitates specific equipment and skilled labor capable of executing those methods safely. Training programs for installers are essential to ensure best practices are followed, reducing the risk of accidents and ensuring high quality installation. Post-installation, it is crucial to maintain communication with customers regarding system performance and any necessary maintenance to optimize energy assessments and prolong the system’s lifespan.

4. REGULATORY FRAMEWORK

The regulatory landscape surrounding solar panel logistics is complex, encompassing local, state, and federal regulations. Entities involved in the solar industry must navigate various laws that govern the installation, operation, and maintenance of solar panels. Understanding these laws is crucial, as compliance is mandatory to avoid legal repercussions and to qualify for available incentives.

In addition to compliance, awareness of changing regulations can influence logistical decisions. For instance, alterations in zoning laws or building codes may necessitate changes in installation practices, thereby affecting the overall timeline and resource allocation of projects. In this context, engaging regulatory experts can offer invaluable insights, helping stakeholders adapt their logistics strategies to evolving legal frameworks while minimizing risks.

5. FUTURE TRENDS

As the solar industry evolves, logistics associated with solar panels is also likely to change. Emerging technologies such as automation and artificial intelligence have the potential to significantly enhance supply chain dynamics. These technologies can improve forecasting accuracy, streamline inventory management, and ultimately reduce operational costs. Additionally, the continuous advancements in transportation methods, including electric vehicles, can result in more environmentally friendly logistics practices.

Furthermore, as consumer demand for sustainable solutions grows, companies are increasingly adopting circular economy principles whereby they seek to minimize waste throughout the lifecycle of solar panels. This approach encourages the reuse and recycling of components, thereby reducing dependence on virgin materials and minimizing overall environmental impact. The logistics planning process must, therefore, adapt to incorporate sustainable practices consider not just transportation and installation but also end-of-life management of solar panels.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE KEY LOGISTICS CHALLENGES IN SOLAR PANEL INSTALLATION?

The primary logistics challenges in solar panel installation include managing transportation of oversized and fragile materials, coordinating skilled labor for installation, and ensuring compliance with local regulations. Effectively addressing these challenges requires strategic planning and real-time communication among all parties involved in solar power projects.

To begin with, transportation poses questions about the best routes, specialized transport vehicles, and methods of securing goods to prevent damages. If panels are damaged during transit, it can lead to costly delays and affect the installation process. Next, skilled labor procurement can sometimes be difficult, particularly in remote locations. Therefore, establishing connections with reliable contractors in advance is essential to guarantee that appropriate personnel are available when needed. Lastly, staying abreast of regulatory changes ensures that installation remains compliant, further minimizing potential disruptions in logistics.

HOW DOES INNOVATION AFFECT SOLAR PANEL LOGISTICS?

Innovation is typically a catalyst for advancement within the realm of solar panel logistics. The introduction of advanced technologies, such as automation, artificial intelligence, and improved tracking systems, can transform traditional practices, rendering them more efficient and effective. For instance, the utilization of predictive analytics will allow operators to better forecast demand for solar panels, particularly during peak seasons.

In addition to forecasting, real-time tracking technology can facilitate a more detailed look at supply chain operations, enabling stakeholders to monitor shipping routes and make data-driven decisions. Innovations in materials handling can also lead to enhanced protective packaging solutions, minimizing damage while reducing transportation costs. Lastly, there is significant potential in the growth of renewable energy solutions; logistics processes must adapt to incorporate smart solutions that ultimately promote sustainable practices while addressing the intricacies associated with the solar panel lifecycle.

HOW CAN COMPANIES IMPROVE THEIR SOLAR PANEL LOGISTICS STRATEGIES?

Companies can enhance their solar panel logistics strategies by focusing on three key areas: collaboration, technology adoption, and sustainability. First, building strong partnerships among manufacturers, logistics providers, and installation professionals fosters synergies that facilitate more streamlined operations. Clear communication and mutual goals often lead to improved efficiency and reduced costs.

Second, integrating advanced technologies into supply chain processes can yield numerous benefits, such as improved tracking of goods and better demand forecasting. This technology allows companies to adapt to shifting market conditions and improve overall operational resilience. Lastly, implementing sustainable logistics practices — from sourcing materials responsibly to minimizing waste during the installation process — not only improves corporate social responsibility but can also strengthen brand reputation in a market inclined towards green solutions.

In summary, logistics for solar panels involves several complex layers that require precise coordination and the effective integration of technology throughout each phase of the process. It starts with a comprehensive understanding of the supply chain, including material sourcing and inventory management, which lays the groundwork for a seamless operational framework. The transportation of solar panels entails specialized handling due to their size and fragility while demanding strategic planning for timely delivery. Installation processes necessitate meticulous coordination among skilled labor, proper equipment, and adherence to local regulations, contributing significantly to the project’s overall success. Moreover, companies must remain vigilant regarding regulatory frameworks that can influence logistics strategies and continuously evolve with innovations that reshape the landscape of solar technology. Emphasizing collaboration, cutting-edge technology, and sustainable practices will continuously improve logistic strategies, ultimately ensuring that solar power remains a viable and robust option for renewable energy. Collectively, these elements form the backbone of effective logistics in the solar panel industry, paving the way for cleaner energy solutions across the globe.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-logistics-does-solar-panels-need/