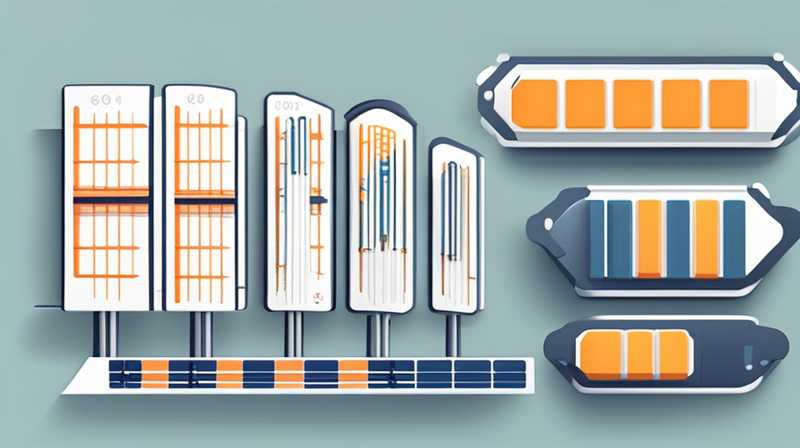

1. Various types of metallic and composite rods are integral in the manufacture of solar panels produced from distinctive raw materials, including 1. Silicon rods, 2. Copper rods, 3. Frame rods, 4. Conductive rods.

Silicon rods serve as the primary component in the production of solar cells, specifically in wafer form after undergoing purification and crystallization processes, resulting in high-efficiency solar panels. These rods undergo various manufacturing stages including purification, crystallization, and slicing into thin wafers, allowing for enhanced energy absorption and conversion efficiency. Other essential rods, such as copper, function in electrical connectivity, showcasing the essential role of conductive materials in optimizing power output.

In addition to these materials, frame rods are typically created from aluminum, giving structural support to the solar panel while also aiding in the dissipation of heat. Conductive rods are often part of the electrical components within the panel, facilitating the flow of energy generated from sunlight. The choice of rods ultimately impacts the performance, efficiency, and durability of solar panels, necessitating careful selection and engineering in their production.

1. SILICON RODS

Silicon rods are pivotal in the solar panel production process, specifically in the creation of solar wafers. Rods of silicon can be categorized into three primary types: monocrystalline, polycrystalline, and amorphous. Each category possesses unique characteristics that influence the efficiency and suitability of solar panels across various applications.

Monocrystalline silicon is derived from a single crystal structure, which gives it a higher efficiency rate and a longer lifespan compared to other types. These rods are typically characterized by their uniform appearance and dark color, signifying a higher grade of silicon purity. They are more expensive to produce due to the intricate processes involved in their creation. In contrast, polycrystalline silicon rods consist of multiple crystal structures. Although generally less efficient than monocrystalline rods, polycrystalline options are cheaper to manufacture. This material often exhibits a bluish hue, marking it as a cost-effective choice for large-scale solar installations.

Amorphous silicon rods, while less common, are used in thin-film solar panels and boast adaptability in various settings, including non-traditional surfaces like building materials and small electronic devices. The choice of silicon type significantly influences the energy output and cost-effectiveness of solar panels. Therefore, manufacturers must analyze their requirements and select accordingly while balancing efficiency, cost, and environmental considerations.

2. COPPER RODS

In the realm of solar panel manufacturing, copper rods are essential components that facilitate electrical connectivity. Copper is recognized for its excellent conductivity, making it a widely selected material for electrical components within solar panels. It is used in wiring and internal connections that transport the electricity generated by solar cells to the inverter and ultimately to the power grid or the energy storage system.

Moreover, copper rods contribute to minimizing energy loss during the transmission of electricity. Unlike other materials that may exhibit higher resistance, copper ensures a smooth flow, thereby increasing the overall efficiency of solar panels. The design of solar panels often includes a copper interconnection process, which links solar cells into a series circuit, allowing for more manageable assembly and energy distribution.

The recyclability of copper is another benefit. As technology progresses, the industry is increasingly focusing on sustainability, and opting for copper supports this initiative. When solar panels reach the end of their lifespan, copper can be recycled and reused, reducing environmental impact. Thus, selecting high-quality copper rods is imperative not only for optimizing performance but also for promoting eco-friendly practices in solar energy production.

3. FRAME RODS

Solar panels require a robust structural framework to ensure durability and resist environmental factors such as wind, rain, and snow. Frame rods, typically constructed from aluminum, serve as the backbone of solar panels. Their lightweight nature does not compromise strength, making them an ideal choice for housing solar cells securely.

These aluminum frame rods provide structural integrity by safeguarding solar panels against physical impacts and environmental stressors. Aluminum is corrosion-resistant, which extends the lifespan of the panels, contributing to maintenance-free longevity. The structural design incorporated in these frame rods enhances the panel’s efficiency as well, allowing for optimal light exposure angles.

The design of frame rods impacts the aesthetics of solar panels as well. Manufacturers have developed various finishes and colors for aluminum frames, enabling seamless integration of solar installations into residential and commercial buildings. Many architects choose aluminum frame rods not only for their functional benefits but also for their ability to match the design of modern constructions. Hence, careful consideration regarding material selection and design plays a crucial role in achieving optimal performance and visual appeal.

4. CONDUCTIVE RODS

Conductive rods are critical components in the intricate wiring network within solar panels. These rods enable efficient electrical conduction, which is vital for channeling the energy harvested from sunlight towards storage or grid systems. Commonly employed materials for these conductive pathways include copper and aluminum, due to their superior conductivity properties.

The role of conductive rods extends beyond merely transmitting electricity; they also assist in maintaining the overall energy performance of the solar panel. The layout of conductive rods within a panel is strategically designed to minimize power losses, ensuring that the maximum amount of energy generated is available for use. This careful engineering contributes substantially to energy efficiency and overall panel performance.

Technological advancements have facilitated the development of enhanced conductive materials that offer increased efficiency and reduce the amount of material required. These innovations not only improve the performance of solar panels but also lower manufacturing costs. Thus, the evolution of conductive rod technologies represents a significant contribution to the renewable energy sector by enhancing the functionality and viability of solar energy systems.

FAQs

WHAT ARE THE MAIN TYPES OF RODS USED IN SOLAR PANEL PRODUCTION?

The principal types of rods utilized in solar panel manufacturing include silicon rods, copper rods, frame rods, and conductive rods. Silicon rods are primarily responsible for converting sunlight into electricity, functioning as the fundamental material for solar cells. Copper rods serve the vital role of connecting these cells and transmitting the generated energy. Additionally, frame rods, typically made from aluminum, provide structural integrity to the panels, while conductive rods ensure efficient flow of electricity through a reliable wiring infrastructure. Each type of rod plays a unique and essential role in maximizing solar panel efficiency and longevity.

HOW DOES SILICON IMPACT SOLAR PANEL EFFICIENCY?

Silicon quality and type play a crucial role in determining the efficiency of solar panels. Higher purity levels directly correlate with increased energy conversion rates. Monocrystalline silicon, for example, typically achieves greater efficiency due to its single-crystal structure compared to polycrystalline and amorphous options. The structure allows for better electron movement, which enhances overall performance. Additionally, advances in production technology are enabling manufacturers to develop silicon rods with improved characteristics. Selecting the right silicon type for specific applications is crucial for optimizing energy output in solar panel systems.

WHAT ARE THE BENEFITS OF ALUMINUM FRAME RODS IN SOLAR PANELS?

Aluminum frame rods offer numerous benefits that enhance the overall performance and durability of solar panels. Firstly, they provide a lightweight yet robust framework, protecting the solar cells from environmental stresses like wind, rain, and snow. Their corrosion-resistant properties ensure that solar panels maintain their structural integrity and visual appeal over time. Furthermore, aluminum frame rods can be crafted in various finishes, allowing for seamless integration into architectural designs. This enhances aesthetic versatility while maintaining structural benefits. Thus, aluminum frame rods are essential for ensuring both durability and visual harmony in solar installations.

Crafting solar panels involves a complex interplay of various types of rods that serve distinct yet integral purposes in their manufacture. Each category—silicon, copper, aluminum, and conductive rods—carries unique qualities that collectively enhance the effectiveness, efficiency, and longevity of the panels. Through a comprehensive understanding of these components and their functions, stakeholders can make informed decisions during the production and installation phases. This understanding is paramount as the solar industry continues to evolve and innovate, driven by the global push for renewable energy solutions and sustainability practices. As such, careful attention to material selection can lead to significant advantages in terms of performance, reliability, and environmental impact. The synthesis of knowledge surrounding these rods aids in the advancement of solar technology, paving the way for a more sustainable future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-kind-of-rods-are-used-to-produce-solar-panels/