What kind of check valve is suitable for solar energy

- The appropriate check valve for solar energy systems varies based on specific installation requirements and fluid dynamics. Factors that influence this decision include material compatibility, pressure conditions, and valve type. The most common types utilized in solar applications are spring-loaded check valves, which provide reliable performance in preventing backflow while supporting effective water circulation. The selection process should consider environmental elements, such as temperature extremes and corrosive agents, as these can significantly impact valve durability.

- Material selection plays a critical role in ensuring the longevity and efficiency of check valves within solar energy systems. Common materials include brass, stainless steel, and plastic, each possessing distinct advantages and disadvantages. Stainless steel, for instance, is highly resistant to corrosion and is suitable for high-pressure applications, making it ideal for many solar energy installations. On the other hand, plastic valves, although generally less durable, offer lightweight and cost-effective solutions, particularly for smaller systems or in environments where low pressure is prevalent.

-

Pressure requirements must also be integrated into the selection criteria. Check valves should be rated to handle the maximum pressure expected within the system. Models with higher pressure ratings ensure safety and functionality, thus minimizing the risk of valve failure and subsequent system issues. It is important to regularly assess pressure levels during solar energy operations to guarantee the valve’s continued efficacy throughout the lifespan of the system.

-

The role of check valves in solar energy systems extends beyond mere prevention of backflow. They facilitate fluid movement, which is crucial for maintaining optimal thermal exchange within solar heating applications. For instance, in a closed-loop solar water heating system, proper circulation is essential for effective energy transfer. Any disruption in this flow can reduce efficiency and compromise system performance. Therefore, selecting a check valve that promotes reliable flow dynamics while preventing backflow is fundamental for maximizing solar energy efficiency.

-

Potential issues related to valve failures also warrant consideration. A malfunctioning check valve can lead to significant operational challenges. For instance, backflow may allow non-thermal water to enter the solar panels, leading to efficiency loss and possible damage. Identifying check valves specifically designed for the expected temperature and pressure ranges helps mitigate these risks effectively. Regular maintenance, including inspections, is advisable to ensure that these components remain functional and do not hint at forthcoming failures.

-

In addition, environmental conditions must be evaluated carefully. For systems installed in areas with high salt concentration or pollutant exposure, the choice to use corrosion-resistant materials becomes imperative. In regions with drastic temperature changes, thermoplastic valves may not withstand the fluctuations, thereby necessitating alternatives like metal valves to ensure ongoing functionality during adverse conditions.

-

The application type also impacts the selection process. For example, in photovoltaic (PV) systems, check valves may be less critical, whereas they play a significant role in thermal solar applications where fluid movement is essential. Understanding the differences in these applications is key to successful integration and helps guarantee efficiency across various setups.

-

Cost is another consideration within the scope of valve selection for solar energy systems. Balancing cost-effectiveness against quality and longevity is crucial. While options like plastic valves may present lower initial expenditures, they may incur greater costs over time due to necessary replacements or repairs. Higher-quality valves, such as stainless steel, often come with a premium upfront but can offer significant long-term savings through reduced maintenance.

-

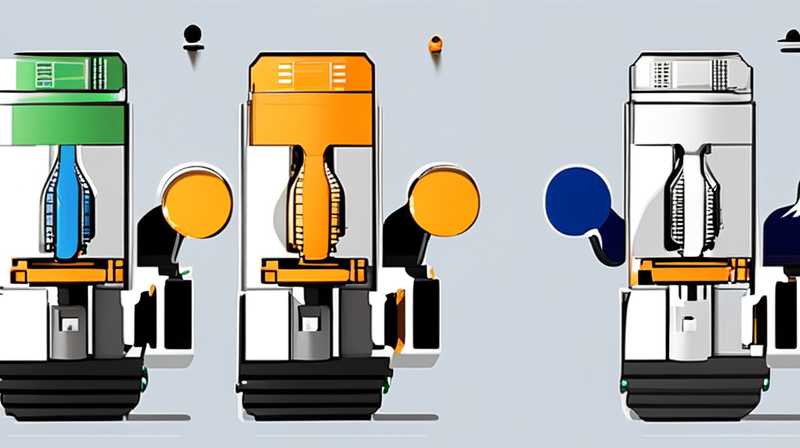

Examining different valve designs is also beneficial. Inline check valves and swing check valves represent two common types utilized in solar applications, with each possessing unique advantages. Inline valves provide compact installations encouraging space-saving arrangements, while swing check valves are generally durable and effective in a range of environments. Identifying which design best aligns with system requirements helps engineers and technicians implement solutions that optimize energy performance.

-

When addressing installation procedures for check valves in solar applications, it’s vital to ensure that the orientation and positioning align with manufacturer guidelines. Correct installation is vital for proper function; deviations may result in malfunction or inefficiencies. This diligence extends to ensuring that the valve is adequately sized and placed within the piping system to minimize potential pressure drop and maintain consistent flow characteristics.

FREQUENTLY ASKED QUESTIONS

WHAT MATERIALS ARE BEST FOR CHECK VALVES IN SOLAR ENERGY?

The optimal materials are largely determined by the specific environmental conditions and operational requirements of the solar system. Stainless steel is often preferred for high-pressure and high-temperature systems due to its excellent corrosion resistance and durability. Conversely, plastic check valves may be suitable for lower pressure systems, particularly where cost-effectiveness is a priority, as they are lightweight and easier to install. It’s important to analyze the chemical compatibility with the fluid in circulation to determine the best choice based on factors like acidity or corrosion potential. For harsher environments, utilizing specially coated metals or high-performance plastics may provide additional protection against degradation.

HOW SHOULD CHECK VALVES BE MAINTAINED IN SOLAR ENERGY SYSTEMS?

Maintaining check valves involves routine inspections to identify any possible leaks or signs of wear and tear. Regular cleaning is necessary to prevent build-up that could compromise the valve’s functionality. It’s advisable to adhere to a maintenance schedule based on the manufacturer’s recommendations and the specific operating conditions of the solar energy system. Additionally, operators should keep an eye on indicators of valve malfunction, such as unusual sounds during operation or significant pressure fluctuations within the system. Any detected irregularities should trigger immediate examination and possible replacement of the valve to ensure continued efficiency.

CAN CHECK VALVES AFFECT THE OVERALL EFFICIENCY OF SOLAR ENERGY SYSTEMS?

Absolutely, check valves are integral to maintaining the flow dynamics within a solar system. Their primary role is to prevent backflow, thereby ensuring a consistent direction of flow that maximizes thermal efficiency. If inadequately designed or poorly maintained, check valves can create resistance, leading to reduced flow rates and broader system inefficiencies. Furthermore, using inappropriate types may compromise the heat transfer process essential for solar thermal applications. Recognizing the necessity of proper selection, installation, and maintenance can significantly impact the operational efficiency of solar energy systems.

The right check valve is essential for the effective operation of solar energy systems, intertwining material choice, pressure capacity, installation accuracy, and environmental adaptability. The selection of an appropriate valve hinges on myriad factors, from the specifics of the fluid involved and the nature of the solar installation to the unique challenges posed by the environment in which the system operates.

Incorporating robust and reliable valves ensures a continuous flow of fluids without backflow, enhancing the system’s performance and increasing the overall efficiency of energy production. Valve selection must involve a thorough analysis of numerous variables, including the type of solar system, operating conditions, and ongoing maintenance requirements. Each component’s ultimate functionality is intertwined with the quality of the check valve chosen, underscoring the importance of thoughtful decision-making in this domain.

Moreover, advancements in valve technology continue to influence the landscape of solar energy applications, presenting opportunities for more efficient designs and materials tailored to meet the challenges of modern energy solutions. Emerging trends in sustainability and renewable energy place a premium on the integration of durable, high-performance components, reinforcing the necessity for ongoing research and development within this sector.

Ultimately, selecting the appropriate check valve is not just a matter of compliance with technical specifications; it implicates the effectiveness of solar energy systems as a whole. By recognizing the interconnectedness of valve performance, system efficiency, and environmental resilience, stakeholders can innovate and advocate for solutions that sustain energy production while minimizing risks and enhancing overall functionality. This holistic approach can drive transformational advancements in how solar energy systems are designed, installed, and maintained in-service, creating pathways to greater energy independence and sustainable operation for future generations.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-kind-of-check-valve-is-suitable-for-solar-energy/