The use of solar cell aluminum molds involves several critical aspects, including 1. Enhancing production efficiency, 2. Ensuring precision in solar cell manufacturing, and 3. Reducing overall costs for production companies. To elaborate, these molds are crucial in shaping and providing consistent dimensions for solar cells, which directly influence efficiency and output. The precision provided by aluminum molds allows manufacturers to maintain tight tolerances that are essential for optimal solar energy conversion. Consequently, the adoption of aluminum molds in solar cell production can lead to significant advancements in both quality and cost-effectiveness.

1. SOLAR CELL MANUFACTURING PROCESSES

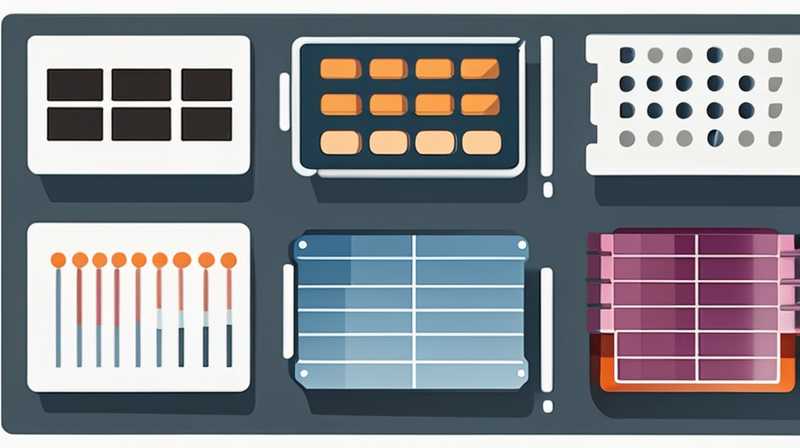

The solar energy industry has witnessed significant growth, driving technological advancements in solar cell production methods. At the heart of this evolution lies the use of molds in crafting silicon photovoltaic cells. Aluminum molds serve as a key component in these processes, facilitating the efficient fabrication of solar cells while ensuring that high standards of quality and performance are met. As technology advances, the importance of aluminum molds in achieving desired shapes, sizes, and surface finishes cannot be overstressed.

Molds not only shape materials but also play a crucial role in the thermal and electrical properties of solar cells. They provide the necessary infrastructure for adhering to strict specifications. Precision engineering is paramount, as misaligned or incorrectly shaped solar cells can lead to decreased energy efficiency and reduced marketability of solar panels. Aluminum molds serve as a reliable solution, helping manufacturers deliver products that meet or exceed standard performance metrics.

2. ADVANTAGES OF ALUMINUM MOLDS

Aluminum molds offer several benefits within the context of solar cell production. The primary advantage is their ability to withstand high temperatures and pressures, which are routine in the production process. Unlike other materials, aluminum maintains structural integrity even under harsh conditions, making it the material of choice for manufacturers. Furthermore, due to their lightweight nature, aluminum molds can significantly reduce the overall weight of production machinery, allowing for easier handling and transportation.

Additionally, aluminum molds provide a high level of thermal conductivity, which is crucial for maintaining uniform temperatures during the manufacturing process. This uniformity helps to prevent defects in solar cells, such as cracking or uneven surfaces, which can adversely affect energy absorption. The molds ensure that each cell receives the same heat treatment, thereby maximizing the overall efficiency of solar panels.

3. COST-EFFECTIVENESS AND EFFICIENCY

One of the most compelling reasons to utilize aluminum molds in solar cell production is the cost-effectiveness they bring to manufacturers. While the initial investment in aluminum molds may be higher compared to other materials, the long-term savings are substantial. The durability of aluminum means that less frequent replacements are necessary, leading to reduced maintenance costs over time. Moreover, the precision that aluminum molds offer reduces waste during the manufacturing process, as the production specifications can be met more consistently.

In addition, the increased efficiency in production processes translates directly into higher profit margins for manufacturers. With more reliable molds, production lines can operate at peak performance with fewer interruptions. This increased throughput allows companies to respond rapidly to market demands, making it easier to capitalize on opportunities in the rapidly evolving solar energy landscape.

4. SUSTAINABILITY CONSIDERATIONS

In an era where sustainability is paramount, the use of aluminum molds in solar cell production aligns with eco-friendly practices. The production of aluminum is significantly less harmful to the environment compared to other materials. Furthermore, aluminum is recyclable, meaning that at the end of their service life, the molds can be repurposed, minimizing waste. This characteristic aligns seamlessly with the renewable energy goals that solar power represents.

Moreover, the energy efficiency of solar panels produced using aluminum molds contributes to a broader vision of sustainability. By leveraging these molds, manufacturers play a vital role in enhancing the efficiency and lifespan of solar technologies, which in turn can help reduce our reliance on fossil fuels. This circular economy approach not only strengthens the industry but also supports global efforts aimed at combating climate change.

5. TECHNICAL INNOVATIONS AND FUTURE TRENDS

Technological advancements continually redefine the landscape of solar cell production. The integration of smart technologies into manufacturing processes, including aluminum mold fabrication, is becoming increasingly prevalent. Innovations such as the use of Artificial Intelligence (AI) in quality control enhance the precision with which molds can be designed and manufactured. As AI systems analyze production data, manufacturers can make real-time adjustments to operations, resulting in even higher yield rates.

Emerging trends point toward a future where molds not only shape solar cells but also incorporate features affecting the efficiency of energy capture. For instance, molded textures that mimic natural phenomena can significantly enhance light absorption, pushing the boundaries of traditional solar technologies. The opportunity for research and development in this area promises exciting advancements that may redefine the established norms of solar cell production.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE PRIMARY MATERIALS USED IN SOLAR CELL PRODUCTION?

The principal materials utilized in solar cell manufacturing include silicon, which is the most common semiconductor used, as well as other materials like cadmium telluride and gallium arsenide. Silicon-based solar cells can be classified into monocrystalline, polycrystalline, and amorphous forms. Monocrystalline cells, crafted from a singular crystal structure, exhibit the highest efficiency rates, while polycrystalline cells, which contain multiple silicon crystals, are relatively less efficient but more affordable. Gallium arsenide cells, notable for their efficiency, are often used in space applications due to their superior performance under various environmental conditions. Cadmium telluride cells are popular for their low-cost production but raise environmental concerns regarding toxicity.

Aluminum molds play a significant role in shaping and producing these materials, providing the necessary structural integrity and precision needed to create high-performance solar cells that meet market demands. The choice of materials and how they are processed can directly impact the overall effectiveness, longevity, and energy production capabilities of solar panels. By understanding the materials and their properties, manufacturers can choose the right combination to optimize solar cell efficiency and sustainability.

HOW DOES TEMPERATURE AFFECT SOLAR CELL PERFORMANCE?

Temperature plays a critical role in the performance of solar cells. As temperatures rise, the efficiency of solar panels tends to decrease because increased heat can hinder the operation of the semiconductor materials within the cells. This phenomenon is primarily due to the increased likelihood of electron hole recombination occurring at higher temperatures. The optimal temperature range for many solar panels is typically between 15°C and 35°C. When temperatures exceed these levels, the power output of solar cells can diminish significantly, potentially leading to efficiency losses of 10% or more.

To combat temperature-related issues, manufacturers employ various strategies, such as the use of thermal management systems and enhanced airflow designs within solar arrays. Furthermore, the application of aluminum molds, known for their excellent thermal conductivity, can help maintain consistent temperatures during the manufacturing process, thereby ensuring that the final product is less susceptible to the negative effects of temperature fluctuations. Innovations in technology continue to address these concerns, leading to the development of materials that can better withstand higher temperatures and maintain performance levels.

WHAT ARE THE EXPECTED FUTURE DEVELOPMENTS IN SOLAR CELL TECHNOLOGY?

The future of solar cell technology is poised for dramatic advancements aimed at enhancing efficiency, reducing costs, and increasing accessibility to renewable energy sources. One of the most anticipated developments involves perovskite solar cells, whose unique crystalline structure promises significant improvements in efficiency over traditional silicon-based designs. Perovskite cells have already demonstrated efficiencies exceeding 25% in laboratory conditions, and ongoing research aims to bring this technology into mainstream manufacturing.

Moreover, innovations in bifacial solar panels—which can capture sunlight from both sides—are gaining traction, leading to further increases in energy yield. Advances in recycling techniques will also play a crucial role in the sustainability of solar energy, ensuring that materials are reused rather than ending up in landfills. The integration of energy storage technologies, such as advanced battery systems, will complement solar power generation by allowing users to store excess energy for later use, making solar power more reliable and user-friendly. These developments highlight the excitement surrounding solar technology, which not only has the potential to dominate the renewable energy landscape but also to contribute significantly to sustainability goals worldwide.

The utilization of aluminum molds in solar cell production significantly revolutionizes the industry by enhancing efficiency, precision, and sustainability. The molds not only facilitate the manufacturing process but also contribute to the overall performance of solar cells, leading to higher energy conversion rates and cost savings. As manufacturers continue to adopt advanced technologies and materials, the role of aluminum molds will likely evolve, ensuring that solar energy remains a pivotal player in combating climate change and promoting renewable energy sources. Such developments will encourage further innovation and research, ultimately contributing to a more sustainable future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-is-the-use-of-solar-cell-aluminum-mold/