What is the structure of solar thermal insulation pipe

1. Understanding Solar Thermal Insulation Pipe Structure:

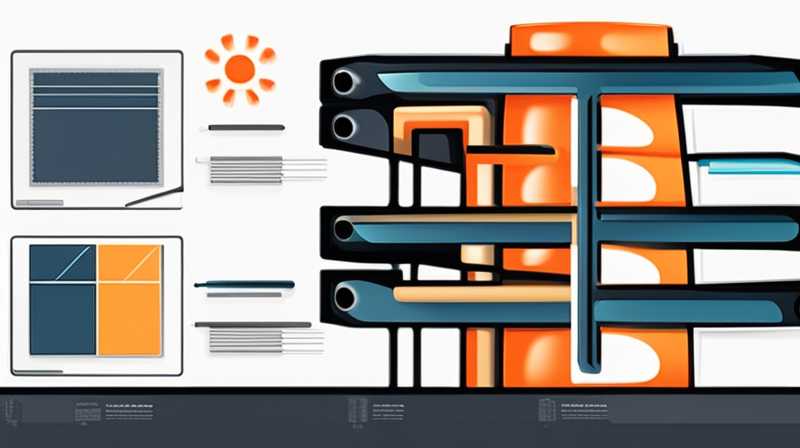

1. The core of a solar thermal insulation pipe comprises multiple layers, 2. each engineered for optimal heat retention, 3. which is essential in maximizing energy efficiency, 4. and ensuring minimal thermal loss over extended periods of use.

A thorough comprehension of its structural composition is vital for those delving into renewable energy technologies, particularly when assessing the efficiency of solar water heating systems. The insulation role of these pipes not only enhances the overall performance but also contributes significantly to reducing energy costs in the long run. The advancement in material technology has led to refined designs that facilitate greater energy capture and retention.

2. LAYERS OF SOLAR THERMAL INSULATION PIPE

The multilayer design of solar thermal insulation pipes serves a pivotal function in insulating the transfer medium, typically a heat transfer fluid or water, from the surrounding environment. Each layer possesses unique characteristics that contribute to the pipe’s overall efficiency.

Insulating Layer Characteristics

The insulation layer is predominantly crafted from materials with low thermal conductivity, such as polyurethane foam or polystyrene. These materials ensure that the heat generated within the pipe remains enclosed, preventing unnecessary loss to the external environment. The selection of an appropriate insulating material is crucial; for instance, polyurethane foam provides superior insulation compared to traditional materials, due to its lower density and excellent thermal resistance. Additionally, the thickness of this insulation layer can significantly impact efficiency—thicker layers generally provide enhanced insulation but require careful consideration of added costs and space.

Outer Protective Layer

Another integral component is the outer protective layer, which is often constructed from weather-resistant materials such as high-density polyethylene (HDPE) or PVC. This outer shell serves to shield the inner layers from environmental factors like moisture, UV radiation, and physical damage. The choice of this protective layer is paramount because it ensures durability and longevity of the insulation pipe, regardless of external conditions. For instance, the UV stabilization treatments often applied to these outer layers can significantly extend their lifespan, reducing the need for frequent replacements or repairs.

3. CONNECTION TO SOLAR COLLECTORS

The interconnection between solar thermal insulation pipes and solar collectors is a critical aspect of the system’s overall design. Understanding this relationship helps clarify how thermal energy is captured and transferred effectively throughout the system.

Thermal Energy Exchange

Solar collectors, typically panels, are designed to absorb sunlight and convert it into heat. The effectiveness of this energy exchange critically hinges upon the design of the insulation pipes connecting these collectors to storage tanks or heating systems. Using materials with high thermal conductivity for the pipe’s inner surface can facilitate efficient heat transfer from the collector to the fluid. However, maintaining insulation integrity in the pipes is equally important, as this prevents heat dissipation during transit. Therefore, the synergy between the collectors and insulation pipes is vital for optimizing energy output from the entire solar thermal system.

Fluid Flow Dynamics

Additionally, the hydrodynamics within the insulation pipe play a significant role. The fluid’s velocity, velocity gradient, and the type of fluid used dictate the efficiency of heat transfer. Ensuring an adequate flow rate is pivotal; too slow a flow may lead to stagnation and inadequate heating, while excessive flow can create turbulence that disrupts the smooth transfer of thermal energy. Hence, calculating appropriate diameters and materials for these pipes, alongside rigorous flow rate assessments, can result in improved efficiency and a significantly enhanced system performance.

4. APPLICATIONS AND BENEFITS OF SOLAR THERMAL INSULATION PIPES

The utilization of solar thermal insulation pipes extends across various domains, from residential to commercial applications, illustrating their versatility within energy systems.

Residential Uses

In residential applications, homeowners leverage solar thermal systems to heat water for domestic use, space heating, and swimming pools. The benefits are manifold: reduced energy bills, lower carbon footprints, and improved energy independence. As homeowners invest in sustainable practices, the integration of solar thermal systems powered directly by such pipes has become a common solution for achieving energy efficiency. Notably, the durability and insulation provided by these pipes can significantly lower maintenance requirements and enhance overall user experience.

Commercial Utilization

On a larger scale, commercial buildings utilize solar thermal insulation pipes in their heating systems, achieving substantial reductions in energy costs. The implementation of these systems in industries, such as food processing and manufacturing, exemplifies how the principles of solar thermal technology contribute to operational savings and sustainability. Companies often realize significant reductions in energy expenditure by employing effective insulation solutions derived from advanced pipe structures. This not only benefits the companies financially but also positions them as forward-thinking entities in the realm of environmental responsibility.

5. EFFICIENCY CHALLENGES IN SOLAR THERMAL INSULATION PIPES

Despite their numerous benefits, challenges also arise surrounding the efficiency of solar thermal insulation pipes, warranting deeper exploration into potential improvements and innovations.

Heat Loss Management

One of the fundamental challenges in maximizing the efficiency of these systems lies in managing heat losses. Even with well-insulated pipes, small amounts of heat can escape due to various factors such as ambient temperature variations and improper installation. Investing in better sealing techniques and high-quality materials can significantly help combat this issue, thereby prolonging the energy’s longevity as it travels through the pipe system.

Technological Innovations

Emerging technologies present opportunities to address existing performance limitations further. The development of nanomaterials, for instance, holds promise for future insulation solutions that could drastically minimize thermal losses while enhancing overall heat conduction properties. Incorporating these next-generation materials could revolutionize solar thermal systems, making them more efficient and economically viable for broader usage across diverse settings.

6. FUTURE TRENDS IN SOLAR THERMAL INSULATION PIPE DESIGN

With advancements in material science and growing emphasis on renewable energy, future trends point toward even greater evolutions in the design of solar thermal insulation pipes.

Sustainability Focus

As sustainability becomes increasingly prioritized globally, new materials that are eco-friendly and recyclable are likely to emerge. The shift away from traditional synthetic materials toward more sustainable options may not only lessen the environmental impact but also meet the growing consumer demand for green technologies. This evolution may shift the landscape of solar thermal systems and accommodate stricter regulatory standards concerning sustainability.

Smart Integration

Additionally, the incorporation of smart technologies into solar thermal systems is a growing trend. Pipes equipped with sensors capable of monitoring temperature and flow rate in real-time can provide significant insights for system optimization. Implementing smart technologies enables users to control and adjust their systems more effectively, thus enhancing overall performance and leading to better energy efficiency in homes and businesses alike.

FAQs

WHAT MATERIALS ARE COMMONLY USED IN SOLAR THERMAL INSULATION PIPES?

Typically, solar thermal insulation pipes consist of a composite of materials designed specifically for thermal retention and mechanical resilience. The innermost layer often utilizes copper or plastic for optimal heat conduction, followed by an insulation layer made of materials such as polyurethane foam or polystyrene, known for their low thermal conductivity. The outer protective layer is frequently fashioned from high-density polyethylene (HDPE) or polyvinyl chloride (PVC). Together, these materials create a robust structure that prevents heat loss, ensuring maximum efficiency for solar thermal systems.

HOW DOES THE INSULATION IN SOLAR THERMAL PIPES AFFECT EFFICIENCY?

The insulation within solar thermal pipes plays a critical role in determining the overall system’s efficiency. Effective insulation minimizes thermal losses that occur when heat transfer fluid travels from solar collectors to storage tanks or heating systems. Insufficient insulation leads to heat loss, resulting in decreased performance and increased energy costs. With advanced materials and properly executed designs, maintaining high insulation performance is achievable, directly correlating with improved energy retention and reduced operational expenses for both residential and commercial applications.

CAN SOLAR THERMAL INSULATION PIPES BE USED IN COLD CLIMATES?

Yes, solar thermal insulation pipes can indeed operate effectively in cold climates. However, in such environments, ensuring adequate insulation is paramount to prevent freeze damage and maintain operational efficiency. The choice of insulating materials and the thickness of the insulation layer become critical factors in reducing heat loss and protecting against freezing conditions. Advanced designs often incorporate additional measures such as heat tracing or integration with auxiliary heating systems for enhanced reliability and performance, thereby ensuring that solar thermal solutions remain viable across various climatic challenges.

RECOMMENDED MAINTENANCE FOR SOLAR THERMAL INSULATION PIPES?

Proper maintenance of solar thermal insulation pipes is essential for sustaining performance and prolonging their operational life. Regular inspections should be conducted to identify and repair any signs of wear or damage to ensure the integrity of the insulation layer. Additionally, cleaning the solar collectors periodically will facilitate optimal energy capture, reducing the workload on the pipes. Monitoring fluid levels and ensuring that the system operates within recommended temperature ranges can greatly contribute to the efficiency and durability of the overall solar thermal system.

BOLD CONCLUSION

The structure of solar thermal insulation pipes is a vital aspect of modern renewable energy systems, playing a crucial role in the efficiency and efficacy of solar water heating applications. By comprehensively understanding their multilayer construction—including insulating and protective layers—one can greatly appreciate the nuances of heat retention inherent to these systems. With advancements in technology, the materials used in these pipes continue to evolve, aiming for greater sustainability and performance. Furthermore, as energy efficiency becomes increasingly essential in the face of climate change, embracing innovations in solar thermal technology can yield significant savings and ecological benefits. The burgeoning integration of smart technologies and eco-friendly materials foretells an exciting future for solar thermal insulation pipes, ensuring their relevance in the ongoing transition to renewable energy. Users who prioritize proper maintenance and vigilant monitoring will reap the full benefits of their investments, contributing to a more sustainable energy landscape while enhancing their energy independence.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-is-the-structure-of-solar-thermal-insulation-pipe/