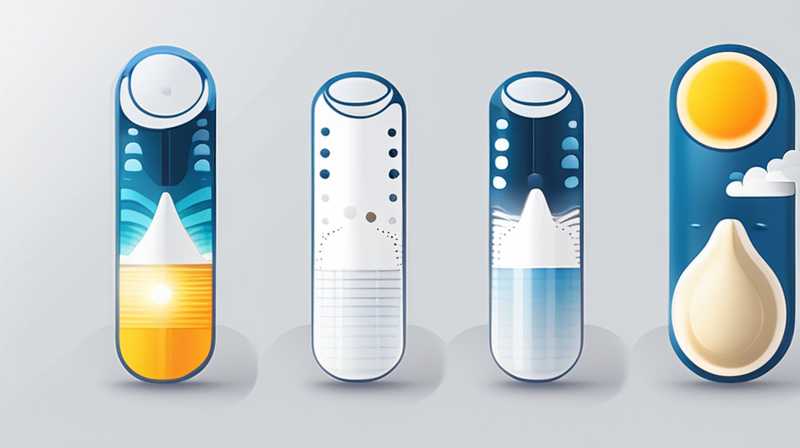

What is the solar liquid filling tube?

This specialized component serves as a critical element in solar thermal systems. 1. It enables heat transfer by filling the collectors with a special thermal fluid, 2. It enhances operational efficiency of solar energy systems, 3. Its construction must withstand high temperatures and pressures, 4. It contributes to the longevity and reliability of solar installations. The thermal fluid, which usually has a high boiling point, circulates within this tube to absorb and transfer heat. The effectiveness of a solar liquid filling tube directly impacts the overall performance of solar thermal technology. Furthermore, advancements in materials and design have been pivotal in optimizing these tubes for sustained performance over extended periods.

1. SIGNIFICANCE OF SOLAR LIQUID FILLING TUBES

Solar liquid filling tubes are foundational components in the realm of solar thermal systems, playing a pivotal role in the functionality of these renewable energy technologies. The integration of such tubes allows for the efficient transfer of heat within solar collectors, transforming solar energy into usable thermal energy. This aspect underscores their importance, as without an effective method of transferring heat, the entire system’s viability would be compromised.

Within the solar thermal setup, these tubes circulate a thermal fluid that absorbs solar energy collected by solar panels. This heated fluid is then transported to storage tanks or directly to heating systems for residential or industrial applications. The substances used in these filling tubes are specifically engineered to maintain optimal performance under variable environmental conditions while exhibiting excellent resistance to thermal degradation. This ensures that heat transfer efficiency remains high.

Furthermore, as advancements in solar technology continue to evolve, the construction materials and design of these tubes have made significant strides. Innovations aim at reducing heat loss and improving heat capacity, essential features for maximizing the efficiency of solar systems. Given the increasing global emphasis on renewable energy sources, understanding the value of these tubes is crucial for both industry professionals and potential adopters of solar technology.

2. MATERIALS AND DESIGN CONSIDERATIONS

The materials selected for solar liquid filling tubes are paramount, as they must endure not only high temperatures but also potential chemical interactions with the thermal fluid used. Common materials include robust metals such as stainless steel, as well as heat-resistant polymers. Each material choice has inherent advantages and potential drawbacks, which must be thoroughly analyzed during the planning stages of any solar installation.

Choosing stainless steel ensures durability; it possesses excellent thermal conductivity while providing protection against corrosion and degradation over time. This longevity translates to lower maintenance costs and fewer system failures, enhancing the reliability of the solar thermal system as a whole. However, these tubes can be relatively heavy, which may necessitate additional structural support.

In contrast, polymer tubes are lighter and offer flexibility in installation, potentially reducing labor costs during setup. Despite their advantages, polymers generally have lower thermal conductivity compared to metals, which might lead to slightly decreased efficiency in thermal transfer. Therefore, the design considerations involve weighing these factors to determine the optimal balance between durability, performance, and installation convenience.

Additionally, the diameter and thickness of the tubes also play significant roles in defining their efficiency. A thicker wall can prevent heat loss but may increase the weight and material costs. The tube’s diameter influences the flow rate of the thermal fluid, where larger diameters may promote faster heat transfer but could also result in increased fluid volume and pump requirements. The interplay between these various design elements must be meticulously assessed to ensure that the solar liquid filling tube fulfills its intended function without compromising the performance of the solar energy system.

3. OPERATIONAL EFFICIENCY AND PERFORMANCE

Operational efficiency hinges on multiple factors, one of which is the thermal fluid’s properties. Selecting a suitable thermal fluid that retains heat effectively and operates within the required temperature range is essential for maximizing performance. Fluids like propylene glycol or water-based solutions are popular choices in many solar heating applications, each with unique thermal characteristics, boiling points, and freezing points.

For instance, propylene glycol is favored for its low freezing point, allowing systems to function effectively even in colder climates. This capability is particularly important as solar installations become increasingly widespread in diverse geographical locations. The choice of thermal fluid must complement the materials used in the solar liquid filling tube to minimize any potential chemical reactions that could degrade the components.

Moreover, the installation accuracy and maintenance of the solar thermal system also significantly influence the operational efficiency of the solar liquid filling tubes. Properly executed connections and sealants minimize the risk of leaks, helping to maintain a consistent fluid flow and ensuring efficient heat exchange. Routine inspections are required to identify potential wear or signs of degradation, which, if left unaddressed, could lead to inefficiencies or system failure.

In addition, advancements in technology such as smart monitoring systems can enhance operational performance. These systems can provide real-time feedback about the conditions within the solar thermal system, helping to optimize fluid flow, detect leaks, and improve overall efficiency. This innovation represents a significant step forward in the management of solar thermal installations, further solidifying the importance of the solar liquid filling tube as a component designed for peak performance.

4. CHALLENGES AND FUTURE OUTLOOK

While solar liquid filling tubes are vital components in the success of solar thermal systems, they aren’t without challenges. External factors such as environmental conditions and materials’ performance under specific stressors can have consequences on their longevity and reliability. For example, extreme temperature fluctuations can lead to material fatigue over time, necessitating the need for routine replacements and updates.

Moreover, factors such as thermal expansion may pose significant challenges in various environments. As the thermal fluid heats up and cools down, the corresponding changes in volume can lead to pressure surges within the system, potentially risking leaks or ruptures if not managed appropriately. Engineers must design systems with these variances in mind, combining advanced materials with a careful approach to tube placement and system configuration.

Looking towards the future, the evolution of technology in the solar sector holds promise for improving the design and functionality of solar liquid filling tubes. Research into advanced materials, such as composites and nano-coatings, aims to create even more resilient tubes capable of enduring adverse conditions while maximizing heat transfer.

In summary, ongoing innovations will likely lead to designs that not only enhance the thermal performance of these tubes but also ensure their sustainability and eco-friendliness. Industry trends indicate a strong push towards integrating smart technologies with the traditional solar thermal systems, allowing for increased efficiencies and tailored solutions.

FREQUENTLY ASKED QUESTIONS

WHAT TYPES OF THERMAL FLUIDS ARE COMMONLY USED IN SOLAR LIQUID FILLING TUBES?

Various thermal fluids are utilized in solar systems, including propylene glycol, ethylene glycol, and water. Propylene glycol is a favored option due to its non-toxic nature and capability to withstand lower temperatures without freezing, making it suitable for colder climates. Ethylene glycol, often used in commercial applications, has a lower freezing point but is toxic, which necessitates careful handling. Water is also widely used due to its high specific heat capacity and availability, although its use is generally limited to warmer climates due to freezing concerns. Each thermal fluid has unique thermal properties, influencing the efficiency and longevity of the system. Additionally, the compatibility of the thermal fluid with the materials of the solar liquid filling tubes is crucial in preventing long-term degradation or potential failure.

HOW DO SOLAR LIQUID FILLING TUBES CONTRIBUTE TO SUSTAINABILITY?

Solar liquid filling tubes are central to the sustainability of solar thermal systems, facilitating the efficient transfer of renewable energy for heating purposes. By harnessing the sun’s energy, these systems help reduce dependence on fossil fuels and lower greenhouse gas emissions. Efficient heat transfer minimizes energy waste, ensuring that solar energy is maximized across various applications. Utilizing innovative materials in the tubes, such as recyclable composites, also enhances sustainability by reducing environmental impacts. Additionally, the longevity and durability of these tubes naturally lead to lower replacement rates and lesser waste over time, strengthening their appeal in sustainable energy solutions.

WHAT MAINTENANCE IS REQUIRED FOR SOLAR LIQUID FILLING TUBES?

The maintenance requirements for solar liquid filling tubes largely involve regular inspections and fluid checks to ensure optimal operation. Inspecting for leaks, corrosion, or any signs of wear is paramount, as these factors can significantly reduce system efficiency. Fluid levels should be monitored, and regular replenishment or replacement of the thermal fluid may be necessary, especially if degradation is observed. It is also essential to ensure that the connections between the filling tubes and other components of the solar system are secure. Additionally, the use of smart monitoring technologies can facilitate preemptive maintenance actions by providing real-time data about system performance and detecting any irregularities before they lead to significant issues.

The significance of solar liquid filling tubes extends beyond their immediate functionality; they embody the essence of efficiency and sustainability in solar thermal technology. As energy demands continue to shift towards renewable sources, optimizing every component within solar systems is vital. The role of the solar liquid filling tube is multifaceted, as it supports not only heat transfer but also the overall sustainability of energy systems. Understanding the material selection and design consideration intricacies further emphasizes the necessity of a robust infrastructure for efficient energy harnessing. The challenges faced, alongside advancements in technology, indicate a future enriched with innovation that promises improved performance and greater resilience, ensuring that solar thermal energy remains a key player in the global energy landscape. Continual investment in research and development will enhance these systems’ capabilities, positively impacting their global adoption rate. Ultimately, as society transitions toward sustainable energy solutions, solar liquid filling tubes will be integral to refining and enhancing solar thermal technologies, putting us on a path toward efficient and eco-friendly energy production.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-is-the-solar-liquid-filling-tube/