The replacement for the solar solenoid valve typically depends on the specific application and system requirements. 1. Common substitutes include electrically operated valves, which can effectively manage fluid flow in solar thermal systems; 2. Mechanical valves, which offer sturdy, manual control; 3. Pneumatic valves, ideal for systems that utilize compressed air; 4. Automated ball or gate valves, which can provide reliable operation with minimal maintenance. The choice of valve hinges on factors such as pressure ratings, compatibility, and operational efficiency.

For instance, electrically operated valves are prevalent due to their ease of integration with electronic controlling systems in solar applications, allowing for precise automated flow control. By understanding various options, users can select a valve that optimally suits their setup requirements.

1. UNDERSTANDING SOLAR SOLENOID VALVES

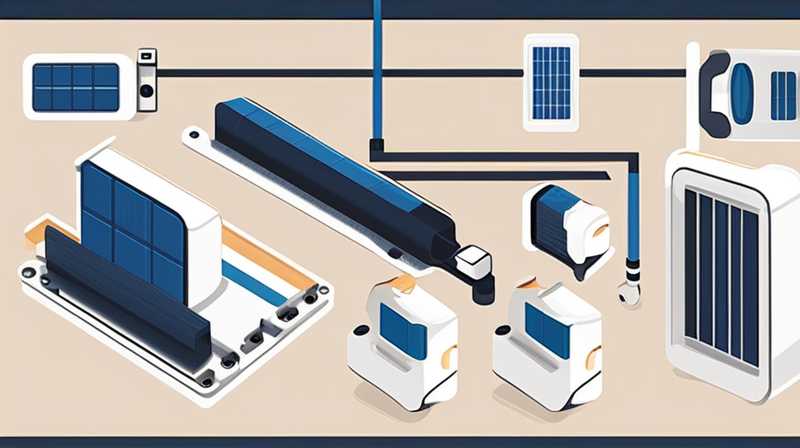

Solar solenoid valves play a pivotal role in the management of fluid dynamics within solar heating systems. They function primarily to control the flow of water or heat transfer fluids, operating in response to electrical signals. The valve opens or closes as determined by the electrical input, allowing for precise regulation of temperature and pressure.

The effectiveness of a solar thermal system often hinges on the reliability of its components, especially the solenoid valve. If the valve fails, it can lead to inefficiencies, increased energy consumption, or even system failure. Therefore, understanding viable replacements is essential for maintaining optimal performance in solar applications.

2. TYPICAL REPLACEMENTS FOR SOLAR SOLENOID VALVES

When seeking alternatives to solar solenoid valves, a variety of options are available, including electrically operated valves, mechanical valves, and pneumatic valves.

A. ELECTRICALLY OPERATED VALVES

Electrically operated valves function similarly to solenoid valves but may come in different designs tailored for specific applications. These valves can be actuated using various electronic control systems, offering users the ability to automate the flow based on environmental conditions or operational needs.

The precision that electronically controlled valves offer makes them suitable for intricate solar thermal systems, where fine adjustments to liquid flow can significantly affect energy efficiency. For instance, systems using sensors to measure temperature differences can utilize these valves to adjust fluid flow dynamically, thus optimizing performance.

B. MECHANICAL VALVES

For applications requiring durability and manual control, mechanical valves present an alternate choice. Unlike solenoid valves, mechanical solutions do not rely on electrical signals, which can be advantageous in environments where power supply is not guaranteed.

These valves operate through manual actuation, allowing operators to physically control the flow. While they may lack the automation features of solenoid valves, their robust design makes them ideal for applications where reliability is paramount. Consider scenarios involving local constraints or conditions where electronic components may be vulnerable; mechanical valves hold significant advantages.

3. PNEUMATIC VALVES AS OPTIONS

Pneumatic valves utilize compressed air to actuate and control fluid flow. They offer distinct advantages, especially in systems where pneumatic energy or air pressure is abundant.

Pneumatic valves provide rapid response times, making them capable of handling quick changes in fluid dynamics. This characteristic proves beneficial in systems where immediate adjustments are essential, such as in large-scale installations that must adapt to variable solar energy outputs.

They also contribute to reducing electrical consumption, thereby optimizing energy efficiency. In environments where maintaining electrical components may be challenging, pneumatic alternatives can enhance reliability without sacrificing performance.

4. AUTOMATED VALVES AND THEIR FUNCTIONS

Automated ball and gate valves represent an advanced category of replacements for solar solenoid valves. They harness modern automation technology to maintain flow control in solar applications, providing the ability to monitor and adjust operations remotely.

The integration of sensors with automated ball valves allows for smart operation. For example, utilizing temperature and pressure sensors can facilitate real-time assessments, enabling immediate adjustments to the system. This adaptability helps to enhance overall efficiency and can significantly extend the lifespan of solar collection systems.

Since these valves can be integrated into broader automation frameworks, they offer users an exceptional degree of control and flexibility, allowing for the creation of smart energy systems that respond to real-time conditions.

5. ASSESSING VALVE COMPATIBILITY WITH SOLAR SYSTEMS

When evaluating replacements for solar solenoid valves, it is crucial to consider compatibility with the existing system architecture. Fluid dynamics, pressure ratings, and material compatibility must all align for effective function.

Valves constructed from corrosion-resistant materials ensure longevity, especially in systems utilizing aggressive fluids or exposed to harsh environmental conditions. Selection should also consider the pressure and temperature ratings of existing components, ensuring all parts of the system operate harmoniously.

The choice of actuators can also influence compatibility. Automated systems may require specialized interfaces and controls, demanding an analysis of existing electrical systems to facilitate effective operation.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE KEY INDICATORS OF A SOLENOID VALVE FAILURE?

Signs of solenoid valve failure can include inconsistent operation, irregular flow rates, or audible leaks. Often, physical inspection reveals wear or corrosion that may affect functionality. Additionally, if a valve fails to open or close as expected, the immediate step should involve testing electrical connections and actuation mechanisms for faults. Regular maintenance can help to identify early warning signs and prevent total system failure.

HOW DO ELECTRICALLY OPERATED VALVES COMPARE TO MECHANICAL VALVES IN TERMS OF COST AND EFFICIENCY?

Electric valves often entail higher upfront costs due to their complexity and additional electronic components. However, they typically offer improved operational efficiency and potentially lower long-term energy costs, particularly in automated systems. Mechanical valves, while more economical, may incur higher operational costs due to their manual nature and lower adaptability in changing conditions. Cost-benefit analyses must consider installation, operation, and maintenance to ascertain the best option for each application.

CAN PNEUMATIC VALVES BE USED IN ALL SOLAR HEATING SYSTEMS?

While pneumatic valves offer robust solutions, their suitability may vary based on specific system designs and requirements. For systems not designed to accommodate compressed air, pneumatic options may present challenges in integration. Moreover, in installations where electronic control systems prevail, adapting to pneumatic components can complicate operations. Thorough assessments of system design and operational strategies are crucial to determine if pneumatic valves are the right choice for particular applications.

Choosing a replacement for a solar solenoid valve entails various considerations that can significantly affect system performance and reliability. The integration of alternative valve types such as electrically operated valves, mechanical variants, pneumatic options, and automated solutions provides a plethora of opportunities for optimization. Understanding these options in detail can guide selection based on specific operational requirements, budgetary constraints, and the overarching goals of renewable energy applications.

In doing so, key factors such as compatibility, operational efficiency, long-term sustainability, and adaptability must be weighed carefully. With advancements in technology, modern systems are increasingly capable of precise control of fluid dynamics, saving energy and extending longevity. Ultimately, a well-informed decision not only enhances operational effectiveness but also contributes to a more reliable and efficient renewable energy framework. Transitioning away from traditional solar solenoid valves allows for a continuation of creativity and innovation in design and operation, ensuring that solar systems can meet evolving energy demands while sustaining ecological considerations.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-is-the-replacement-for-the-solar-solenoid-valve/