1. Solar tubes can explode due to various reasons, including inadequate pressure management, manufacturing defects, and environmental conditions that exert stress on the materials.

2. Among these, inadequate pressure management is particularly critical. This occurs when the internal and external pressures exerted on the solar tube are not adequately balanced, leading to potential rupturing or explosive failure of the tube.

1. OVERVIEW OF SOLAR TUBES

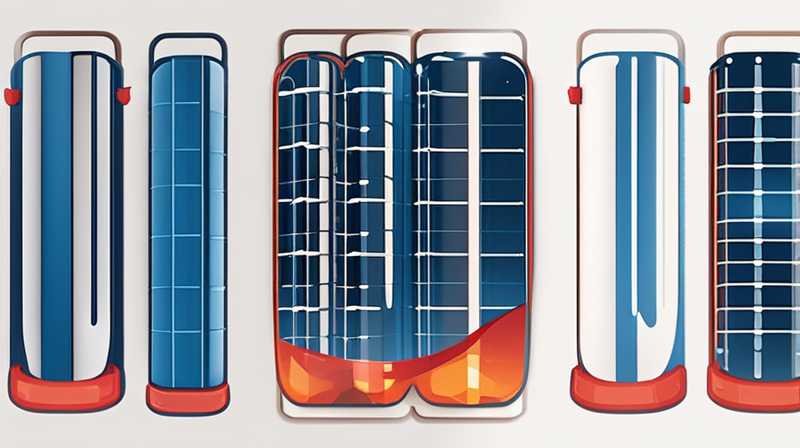

Solar tubes, also known as solar tubes collectors or solar tubes systems, are innovative technologies designed to harness solar energy efficiently. Their main function is to capture sunlight and convert it into thermal energy, which can be used for various heating applications such as water heating, space heating, and pool heating. Comprised of a cylindrical shape filled with specialized materials, solar tubes maximize exposure to sunlight while minimizing heat loss.

The fundamental advantage of these systems lies in their ability to produce energy even in less-than-ideal conditions, such as cloudy days or in areas with lower sunlight intensity. Through the use of double-walled glass structures, solar tubes create a greenhouse effect, allowing captured sunlight to be transformed into heat efficiently. However, along with these benefits, certain risks accompany their use, one of which is the potential for explosive failure under certain conditions.

2. FACTORS LEADING TO SOLAR TUBE EXPLOSIONS

A variety of factors can contribute to the catastrophic failure of solar tubes. Among them, inadequate pressure management is significant. Solar thermal systems operate under specific pressure levels, and any discrepancies can lead to dangerous situations. When excess pressure builds up inside the tube without adequate release mechanisms, the structure may yield to the internal stress, resulting in an explosive rupture.

Moreover, manufacturing defects can play a pivotal role. Materials used in constructing solar tubes are subjected to rigorous quality control. Nevertheless, lapses in the manufacturing process, such as poor adhesion of the heat-transfer fluids or microscopic flaws in the glass structures, can compromise their integrity. This imperfection may not be immediately observable but can lead to serious malfunctions later.

Additionally, environmental influences cannot be overlooked. Extreme weather conditions, such as high temperatures or abrupt temperature fluctuations, alongside external factors like hail impacts, may create stress on solar tube structures that are not designed to endure such forces. Regular monitoring of these systems allows for early detection of potential issues, thus mitigating the risk of failure.

3. UNDERSTANDING PRESSURE DYNAMICS

Pressure dynamics is crucial in understanding how solar tubes function and the risks associated with them. The internal and external pressures must remain consistent to ensure the safe operation of these systems. Sunlight heats the fluid within the solar tube, which expands, increasing the internal pressure. A properly designed solar tube should have mechanisms in place to alleviate this pressure, such as pressure relief valves, which facilitate a controlled release of built-up pressure.

When these systems are installed, it is vital to ensure that they adhere to appropriate pressure specifications. Models should be selected based on the expected heating load and local climate conditions. Failure to consider these aspects can lead to an imbalance in pressure management that may eventually culminate in an explosion.

Furthermore, temperature regulation directly influences pressure management. As the temperature increases, so does the pressure inside the tube. A well-insulated solar tube will lessen heat loss, ensuring it remains efficient; yet, this could also result in elevated pressure levels if not managed correctly. Users and installers of solar tube systems must familiarize themselves with how to maintain appropriate temperatures to reduce the possibility of dangerous pressure spikes.

4. THE ROLE OF MATERIALS

The materials selected for manufacturing solar tubes are essential for both efficiency and safety. High-quality materials ensure the longevity and functionality of the structure. Common components might include special glass designed to withstand extreme temperatures, stainless steel or aluminum for durability, and thermal insulation materials.

Using inferior or incorrect materials can yield disastrous results. For instance, glass that is not of sufficient thickness or quality may crack or shatter, compromising the structural integrity. If left unmonitored, this could become a critical hazard. For this reason, it is crucial to purchase solar tubes from reputable manufacturers who adhere to strict regulations regarding manual and mechanical testing.

Furthermore, thermal expansion rates of materials used must be compatible. Different materials expand and contract at various rates when subjected to temperature fluctuations. When incompatibility among materials exists, it can lead to mechanical failure. Therefore, integrating advanced materials engineering practices during design and production processes is essential in minimizing risks related to pressure and explosive failure.

5. ADVANCED TECHNOLOGIES AND INNOVATIONS

In an ever-evolving field, continuous enhancements in technology offer innovative solutions for existing problems related to solar tubes. Advanced monitoring systems have been developed to provide real-time data about temperature and pressure within solar tube collectors. Such systems can alert users to unusual conditions before they escalate to hazardous levels.

Moreover, smart materials that change properties in response to external conditions represent a promising avenue to enhance safety. For example, shape memory alloys can act to relieve pressure under extreme thermal conditions, reducing reliance on traditional mechanical components. Such innovations highlight the ongoing commitment to improving both performance and safety in renewable energy technologies, emphasizing the importance of adapting to future challenges.

6. MAINTENANCE AND SAFETY PROTOCOLS

Implementing routine checks and maintenance can significantly lower the risk of catastrophic failures in solar tubes. Users should establish a schedule for inspections that include looking for signs of wear and tear, pressure inconsistencies, and potential leaks in the system. Regular maintenance can also involve cleaning the tube’s surface to maximize solar absorption and identifying potential issues through visual inspections.

Furthermore, adhering to safety protocols and guidelines laid out by manufacturers is non-negotiable. These guidelines provide crucial information on installation, operation, and management of the system and should be sufficiently emphasized to end users and technicians alike. By doing so, risks can be mitigated, ensuring that solar tube systems remain safe and efficient in producing renewable energy.

7. LEGISLATION AND STANDARDS

Regulatory frameworks have emerged to guide the safe installation of solar tubes globally. Government agencies and international organizations have developed standards that govern manufacturing practices, installation guidelines, and performance metrics for solar thermal systems. Adhering to such standards fosters an environment of safety and reliability within the solar energy industry.

Regular assessments conducted within these frameworks also allow manufacturers to verify compliance with safety standards, thus ensuring quality control throughout production processes. Continuous improvements in legislation will invariably play a crucial role in minimizing the risks of solar tube explosions and ensuring an efficient, sustainable energy future.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE WARNING SIGNS OF A POTENTIAL SOLAR TUBE EXPLOSION?

Several warning signs may indicate an impending failure of solar tubes. Of particular concern are significant pressure fluctuations and unusual noises, such as hissing or popping sounds. Users should also look for visual deformities, cracks, or discoloration on the tube’s surface. Regular maintenance checks can help detect any abnormalities before they escalate into hazardous situations—keeping an eye on the efficiency of heat transfer can also serve as an indicator for the health of the system. When monitoring these factors, it is crucial to act swiftly if abnormalities are noticed; preventive measures often save considerable trouble and expense. Furthermore, installing automated monitoring systems can enhance early detection, ensuring that any dangerous pressures or temperatures are addressed promptly.

HOW CAN SOLAR TUBE SYSTEMS IMPROVE ENERGY EFFICIENCY?

Solar tubes significantly enhance energy efficiency by utilizing advanced materials and designs to capture sunlight more effectively. By creating a vacuum between the glass layers of the solar tube, heat losses due to convection or conduction are minimized, allowing the system to maintain its thermal energy for longer durations. Additionally, the design of solar tubes facilitates better integration with existing heating systems, thus optimizing overall energy usage. Consumer systems calibrated for particular environmental conditions also increase efficiency, responding dynamically to changes in temperature and sunlight intensity. Overall, continual improvements in technological design, materials used for construction, and system integration lead to more efficient solar tube functionality.

WHAT REGULATIONS GOVERN SOLAR TUBE INSTALLATION AND MAINTENANCE?

Various regulations and standards oversee the installation and maintenance of solar tubes, varying by country and region. Generally, these regulations revolve around safety, quality assurance, performance benchmarks, and manufacturing requirements. Reputable manufacturers shall ensure adherence to local building codes and guidelines, which often involve thorough assessments and certifications before approval for use. Local authorities might require regular inspections conducted by certified professionals, following set protocols to ascertain the systems’ operational safety. Keeping up with changing regulations and implementing necessary updates is vital for system operators to maintain compliance and safety standards consistently.

In conclusion, comprehending the factors that lead to the explosion of solar tubes is critical for users, manufacturers, and policymakers alike. Adequate pressure management, which includes maintaining a balance between internal and external pressures, emerges as the most significant contributor to preventing explosive failures. Furthermore, recognizing the role of manufacturing defects and environmental influences allows for enhanced vigilance and proactive measures to address potential risks effectively. It is imperative to highlight that rigorous monitoring of pressure dynamics, usage of high-quality materials in construction, and forward-thinking innovations are all essential components in mitigating the hazards associated with solar tubes. Ongoing maintenance and adherence to regulatory standards are also paramount in ensuring safe and efficient operation of solar thermal systems while fostering public safety. As solar technology continues to advance, understanding and responding to these concerns remain pivotal in maintaining user confidence and promoting sustainable energy practices globally. Thus, continual research, inspection, and adherence to best practices will pave the way for safer and more efficient solar energy utilization in the future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-is-the-reason-for-the-explosion-of-solar-tubes/