To determine the normal resistance of the solar panel relay, it is essential to understand that the resistance value typically ranges between 1 to 10 ohms, though various factors such as the specific relay model and environmental conditions can influence this range. 1. Correct resistance measurement is crucial for optimal relay function, as excessive resistance may hinder effective current flow, causing operational inefficiencies. 2. Understanding the ratings helps in selecting the right relay for solar panel applications. 3. Regular checks can prevent faults that lead to system failures. 4. Knowing the normal resistance ensures that users can readily identify any abnormalities in relay performance. By maintaining awareness of these parameters, one can optimize the relay’s functioning within the solar energy framework, thereby enhancing overall efficiency and reliability.

1. UNDERSTANDING RELAYS IN SOLAR ENERGY SYSTEMS

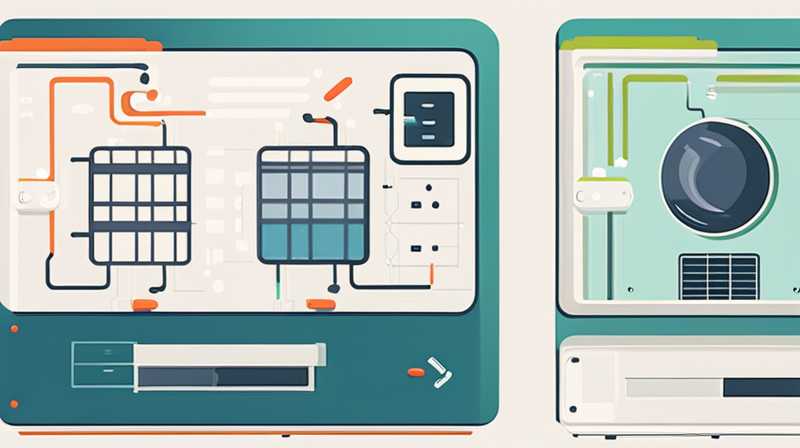

Relays function as electromechanical switches that are vital in many electronic and electrical systems, including solar energy applications. Their role becomes particularly significant in controlling circuit connections efficiently. Electromechanical relays work by utilizing a coil that, when energized, creates a magnetic field to mechanically move a switch. This mechanism enables precise control over the charging and discharging cycles of solar batteries, managing loads effectively. As solar energy systems are increasingly adopted globally, understanding how these components work and their significance in the overall power management becomes crucial for any potential or established solar energy user.

In solar setups, relays are employed for various reasons, such as preventing reverse current flow, managing multiple power sources, and switching loads on and off. The normal resistance of the relay is integral to its operation, reflecting the relay’s ability to conduct electricity without generating excessive heat. High resistance in a relay can lead to voltage drops that might prevent the system from performing optimally, demonstrating the importance of maintaining nominal resistance levels for reliable energy output.

2. MEASURING RESISTANCE IN RELAYS

Understanding how to measure resistance accurately in a relay can mitigate potential risks and enhance functionality. Initially, one must ensure that the relay is disconnected from the power source as measuring resistance while the relay is engaged could yield inaccurate readings and cause damage to the multimeter. Using a digital multimeter (DMM), the probes should be placed on the relay’s terminals. The reading displayed will indicate the resistance level, which, for most standard solar panel relays, should typically range between 1 to 10 ohms. If the reading significantly deviates from this range, it may indicate that the relay is either in need of maintenance or replacement.

To elaborate further, the type of relay employed can determine the specific resistance value expected. Different relays are designed for varied loads and environmental conditions; hence, detailed specifications from the relay’s manufacturer should be consulted. For instance, some marine-grade relays might present different resistance readings due to their construction to withstand harsh conditions. Regular measurements and understanding the context of these values empower users to take informed actions in maintaining their solar energy systems securely.

3. FACTORS AFFECTING RELAY RESISTANCE

Many underlying aspects can influence the resistance of solar panel relays, ranging from environmental conditions to aging components. Significant changes in temperature, humidity, and exposure to corrosive elements can cause the resistance values to deviate from their nominal readings. High temperatures can lead to physical expansion of materials, modifying their conductive capacities, while humidity can affect connections, leading to increased resistance that may impede the circuit’s efficiency. Thus, awareness of these environmental impacts is necessary for maintaining optimal system performance.

Additionally, the aging of the relay itself plays a critical role in resistance changes. Over time, contacts within the relay can wear out, introducing more resistance and potentially leading to failures under load. Frequent cycling of the relay is another factor; the more often a relay is activated, the more wear and tear it experiences. Users should establish a periodic inspection schedule to verify the state of their relays, ensuring that resistance values remain within acceptable parameters to prevent system failures and enhance the longevity of the solar energy installations.

4. SIGNIFICANCE OF PROPER RELAY MAINTENANCE

Regular maintenance of relays not only guarantees their effective operation but also ensures the entire solar energy system remains healthy and efficient. Neglecting maintenance could lead to increased resistance in the relays, reduced performance of the solar panels, and potential system failures. Inspection protocols should include checking the mechanical parts of the relay, cleaning contacts, and ensuring that connections are secure. This proactive approach helps identify issues before they escalate, saving both time and resources in the long run.

Moreover, educating users about the normal operating conditions and resistance values of relays introduces a layer of reliability to solar energy systems. Awareness encourages users to take action when values vary significantly from the norm. When relays are well maintained, they operate in their intended resistance ranges, which plays a pivotal role in optimizing overall energy conversion efficiency.

FREQUENTLY ASKED QUESTIONS

WHAT CAUSES HIGH RESISTANCE IN RELAYS?

High resistance in relays can stem from a variety of factors. One of the primary causes is contact wear, resulting from continuous mechanical movement during operation. This wear creates a layer of oxidation or debris on the contacts, preventing optimal electrical flow. Corrosion is another concern, particularly in systems subjected to moist or saline environments. Protective measures, such as using relays rated for specific environmental conditions, can mitigate these risks. Regular maintenance and inspection are essential practices to prevent high-resistance scenarios in relays.

Additionally, improper installation could also contribute to increased resistance. Misalignment of components, wrong connections, or inadequate soldering can introduce resistance that was not part of the design. Furthermore, temperature fluctuations may exacerbate resistance changes in relays. High temperatures can cause expansion and contraction of the materials, ultimately compromising their functionality. Thus, maintaining appropriate installation procedures and regularly checking the relays will help ensure they work within normal resistance specifications.

HOW DOES TEMPERATURE AFFECT RELAY RESISTANCE?

Temperature has a profound influence on relay resistance, with both excessive heat and cold potentially affecting performance. High temperatures can lower resistance by increasing the conductivity of the relay’s materials, but if the temperature exceeds certain thresholds, material degradation occurs, which can lead to failures. Conversely, low temperatures can increase resistance, as reductions in thermal energy can cause materials to contract, adversely affecting contact areas. Such resistance fluctuations can lead to relay malfunction or diminished efficiency in solar panel operations.

Climate considerations become increasingly significant when deploying solar energy systems in diverse geographic locations. For instance, areas with extreme heat should utilize relays designed to withstand high-temperature environments while considering the effects of localized heat generation, such as proximity to inverters. Similarly, sites subjected to cold weather conditions may require relays with low-temperature ratings to assure reliability in electrical connections. By understanding the temperature limitations and ranges of resistance values, users can select the right components that ensure perpetual operational efficacy in varying ambient conditions.

WHAT ARE COMMON SIGNS OF A FAULTY RELAY?

Identifying a faulty relay promptly is imperative for maintaining the efficiency of a solar energy system. One of the most noticeable signs is the presence of a clicking sound that is inconsistent or absent when controls engage the relay. This irregularity often signifies internal mechanical issues or worn components that fail to complete the conductive bridge. Additionally, abnormal heating or burning smells are strong indicators of trouble; when resistance within the relay is significant, excess heat can build up and potentially damage the surrounding infrastructure.

Another significant sign includes inconsistent system performance – for instance, if the solar panels are underperforming while extra energy is sent to batteries more often than anticipated, the relay might be malfunctioning. A multimeter test revealing resistance outside the normal range of 1 to 10 ohms further underscores the need for immediate remedial action. Observing these symptoms enables users to act expeditiously to either repair or replace relays, ensuring optimal functionality and sustainability of the entire system.

In summation, understanding the normal resistance of solar panel relays, typically between 1 to 10 ohms, is vital for the efficient operation of solar energy systems. Thoroughly measuring resistance is essential to ensure that relays function properly, with regular upkeep necessary to avoid increased resistance due to environmental factors or component aging. Various causes, such as mechanical wear, corrosion, or temperature changes, can influence resistance readings, emphasizing the significance of inspecting and maintaining these critical components. Users must remain vigilant about signs of relay distress, as identifying faulty components early can prevent costly downtime and system inefficiencies. Knowledge about relay resistance ultimately empowers users to make informed choices, ensuring that solar energy systems remain reliable, efficient, and compliant with energy demands. Regular education on these parameters and proactive maintenance practices can substantially enhance the performance and longevity of solar installations, creating opportunities for sustainability and energy independence across different sectors.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-is-the-normal-resistance-of-the-solar-panel-relay/