Normal air pressure in an energy storage tank is typically between 10 to 50 psi (pounds per square inch), 1. Variations in pressure levels depend on the specific application and storage medium, 2. It is critical to maintain appropriate pressure to ensure efficient energy storage, 3. Regular monitoring and adjustments safeguard against operational issues, 4. The maintenance of these pressure levels is closely tied to the tank’s design and the regulatory standards governing energy storage systems.

1. UNDERSTANDING AIR PRESSURE IN ENERGY STORAGE TANKS

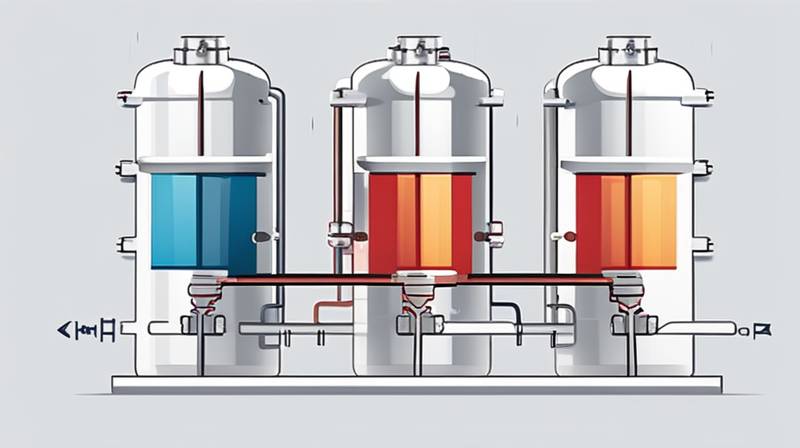

Energy storage tanks serve a pivotal role in various industries, particularly in the fields of renewable energy and industrial applications. At the heart of these tanks lies the concept of air pressure, which is essential for storing energy in a balanced and efficient manner. An understanding of what constitutes “normal” air pressure in these systems is foundational for operators and engineers alike. Specific applications, such as compressed air energy storage (CAES), have unique requirements that differ depending on the purpose and design of the tank.

The pressure within an energy storage tank can be influenced by factors including the ambient temperature, the type of energy being stored, and the tank’s structural integrity. For instance, in CAES systems, air is compressed during periods of low electricity demand and released to generate power when demand is higher. Understanding the baseline, or normal operating pressure, is vital to ensuring these systems operate safely and effectively.

2. INFLUENCING FACTORS ON AIR PRESSURE

Several variables impact the air pressure levels within energy storage tanks. Seasonal changes, mechanical factors, and external environment conditions can significantly affect the internal dynamics of a tank. For instance, fluctuations in ambient temperature can lead to thermal expansion or contraction of storage gases, altering internal pressure readings. Operators must remain vigilant about these changes, primarily during seasonal transitions.

Moreover, the design of the tank itself can act as a determining factor. Tanks constructed with different materials may absorb or disperse heat differently, influencing the gaseous contents’ state. This mechanical interaction can create variability in pressure that must be continuously managed. To sustain optimal operating conditions, regular assessments of both the mechanical integrity of the tank and its internal pressure remain indispensable.

3. REGULATORY STANDARDS

Adherence to regulatory standards plays a critical role in the maintenance of air pressure within energy storage tanks. Compliance with safety regulations set forth by organizations such as the Occupational Safety and Health Administration (OSHA) or the American Society of Mechanical Engineers (ASME) is paramount. These standards often stipulate specifications regarding maximum allowable pressure, tank material integrity, and safety protocols for pressure monitoring.

Operators must perform routine inspections and preventive maintenance to align with these regulations. This involves checking gauges, testing pressure relief valves, and overseeing automated systems that monitor pressure levels. Such diligence aids in preventing pressure-related incidents that could arise from neglecting regulatory compliance.

4. MONITORING AND MAINTENANCE

Effective monitoring and maintenance practices are essential for sustaining normal air pressure in energy storage tanks. Implementing automated monitoring systems can provide real-time data to operators, significantly enhancing awareness of pressure fluctuations. Modern technology, including IoT (Internet of Things) solutions, facilitates remote monitoring capabilities, allowing for timely interventions when readings fall outside predetermined thresholds.

Scheduled maintenance activities should also incorporate thorough checks of pressure regulators and relief valves, which are critical components in sustaining safe pressure levels. Regularly calibrating instruments ensures that operators receive accurate data, thus enhancing safety measures and operational efficiency. Establishing a routine for these activities promotes prolonged durability of tank systems and enhances overall safety protocols within the energy storage industry.

5. COMMON APPLICATIONS OF ENERGY STORAGE TANKS

Energy storage tanks have diverse applications, from residential use to large industrial settings. Devices utilizing compressed air for energy storage embody a prominent example. In such systems, air is compressed and stored in tanks at high pressure, allowing for energy to be generated when required. This model is particularly advantageous in managing energy generated from intermittent renewable sources such as wind or solar power.

Another application lies in heating and cooling systems. Thermal energy storage tanks work by storing thermal energy produced during low-demand periods, making it available during peak demand times. Often found in commercial buildings, these tanks provide a cost-effective mechanism for managing energy use while mitigating stress on the grid. The effectiveness of these systems hinges on maintaining normal air pressure, which underscores their operational reliability and efficiency.

6. TROUBLES IN MAINTAINING AIR PRESSURE LEVELS

Many challenges can arise in the attempt to maintain normal air pressure in energy storage tanks. Equipment malfunction, human error, and environmental factors can all lead to deviations from required pressure levels. For instance, leaks in the tank or compromised seals can result in a gradual loss of pressure, which may go undetected until significant operational issues occur.

Mitigating these challenges involves implementing a robust training program for personnel handling these systems. Comprehensive training should include understanding the importance of normal air pressure and recognizing early warning signs of pressure loss, such as fluctuating gauge readings or abnormal sounds from the tank area. Continuous education fosters a culture of safety and awareness, thereby decreasing the likelihood of incidents ranging from minor setbacks to major system failures.

7. TECHNOLOGICAL ADVANCEMENTS IN PRESSURE MANAGEMENT

Advancements in technology are continually shaping the landscape of energy storage and pressure management. The integration of smart sensors and automation systems into energy storage tanks allows for enhanced data collection and predictive analytics. Such technology aids in determining the conditions under which pressure changes may occur and enables operators to preemptively address potential issues.

Data analytics techniques can improve decision-making and operational efficiency by providing insights into pressure trends and storage performance. These innovations pave the way for smarter, more effective air pressure management strategies, ensuring that energy storage tanks operate within safe and efficient parameters.

8. STRATEGIES FOR OPTIMIZING AIR PRESSURE

To achieve the best performance when utilizing energy storage tanks, operators should implement effective strategies for air pressure optimization. Regular pressure calibrations, along with systemic checks of all relevant systems, can ensure that pressure levels remain stable.

Effective communication and training programs play a crucial role in enhancing operational efficiency. Ensuring all personnel understand the significance of maintaining normal air pressure and are equipped to handle unexpected fluctuations can help mitigate risks. Moreover, establishing an action plan that outlines steps to be taken in case of pressure anomalies ensures quick responses to any potential issues.

COMMON QUERIES

WHAT ARE THE CONSEQUENCES OF LOW AIR PRESSURE IN ENERGY STORAGE TANKS?

Inadequate pressure can lead to suboptimal energy storage performance. Energy recovery rates may decrease, diminishing the overall efficiency of the system. Moreover, if pressure drops below specified levels, it can result in mechanical failure or an inability to generate energy, especially in compressed air applications.

The overall reliability of the storage mechanism also becomes compromised. Failure to maintain sufficient pressure can cause operational interruptions and even pose safety hazards if the system fails to activate pressure relief measures. Therefore, it is imperative to maintain the appropriate pressure within tanks to ensure they function as intended and remain safe for all users.

HOW DO EXTERNAL CONDITIONS IMPACT AIR PRESSURE IN STORAGE TANKS?

External environmental factors play a significant role in determining the internal pressure of energy storage tanks. Temperature fluctuations experienced in various seasons can cause gases to expand and contract, directly affecting pressure levels. During extreme temperatures, whether high or low, the tank’s contents may experience significant changes in pressure, potentially leading to an operational imbalance.

Additionally, changes in the atmospheric pressure can influence the behavior of the gases inside the tank. Therefore, it is crucial for operators to consider surrounding environmental conditions when assessing air pressure levels and to employ compensatory measures to preserve optimal operating conditions.

WHAT TECHNOLOGIES ARE ESSENTIAL FOR MONITORING AIR PRESSURE IN ENERGY STORAGE TANKS?

An array of technologies is increasingly necessary for effective pressure monitoring in energy storage tanks. Pressure gauges remain fundamental, offering immediate readings for quick assessments. However, more sophisticated technologies, such as smart sensors connected to IoT systems, provide real-time monitoring capabilities, alerting operators to any changes in pressure levels instantly.

Automated pressure regulation systems can significantly enhance safety and operational efficiency, as they autonomously adjust and correct pressure levels to maintain the needed balance. This integration of technology enables proactive management and minimizes risks associated with human error or oversight.

Establishing and maintaining normal air pressure in energy storage tanks is indispensable for optimal operational efficiency and safety. Attention to detail, adherence to regulatory standards, and employment of technology and training initiatives are pivotal to sustaining these pressure levels. Inadequacies in pressure management can lead to significant consequences, including reduced efficiency, higher operational costs, and safety risks. Therefore, a meticulous approach, underscored by continuous monitoring and proactive maintenance, ensures that these energy storage systems operate reliably and effectively. Ultimately, the synergy of advanced monitoring technologies, well-informed personnel, and a commitment to safety measures will pave the way for enhanced performance and safety in energy storage tank operations.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-is-the-normal-air-pressure-in-the-energy-storage-tank/