1. No-load voltage refers to the maximum voltage produced by a solar panel when it is exposed to sunlight but not connected to any load, typically measured in volts. 2. This voltage varies based on factors such as panel types, environmental conditions, and temperature. 3. Generally, crystalline silicon panels exhibit higher no-load voltages, while thin-film technologies present lower voltages. 4. Environmental factors, including temperature and irradiance levels, significantly influence the measured no-load voltage, making these values essential for optimizing solar energy systems. 5. Understanding this voltage is crucial for designing efficient energy systems, ensuring compatibility with inverters and batteries. 6. Proper knowledge of no-load voltage assists in system planning and the identification of potential energy losses or inefficiency.

1. UNDERSTANDING NO-LOAD VOLTAGE

The concept of no-load voltage holds significant importance in the realm of solar energy systems. This parameter reflects the maximum electrical potential that a solar panel can generate under standard conditions when it is disconnected from any electronic load. When measuring this voltage, the panel is explicitly exposed to sunlight, and no current is drawn from it. Consequently, the no-load voltage provides a benchmark for understanding the efficiency and capabilities of solar technology.

Several factors affect the no-load voltage readings from solar panels. Irradiance, which pertains to the amount of solar radiation received per unit area, plays a crucial role. Higher irradiance levels typically result in increased voltage output, while lower levels can diminish performance. Additionally, temperature is another critical variable—higher temperatures can lead to reduced voltage due to thermal effects, potentially impacting the overall efficiency of the solar system.

2. VOLTAGE RANGES FOR DIFFERENT SOLAR PANEL TYPES

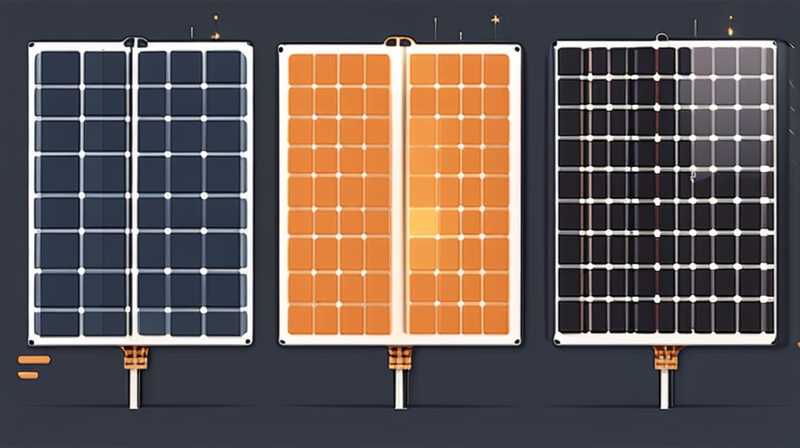

When exploring the no-load voltage derived from various types of solar panels, it becomes apparent that there exist distinctions across technologies. For instance, monocrystalline silicon panels tend to generate higher no-load voltage in comparison to their polycrystalline and thin-film counterparts. Monocrystalline solar panels generally have a no-load voltage ranging from 36 to 40 volts, which is advantageous for systems requiring higher voltage outputs. This increase in voltage correlates with their higher efficiency rates and performance.

In contrast, thin-film solar panels often have lower no-load voltage readings, typically falling between 20 to 30 volts. Although these panels have lower efficiency ratings, they present benefits such as flexibility and lightweight construction, making them suitable for specific applications, such as building-integrated photovoltaics. Ultimately, understanding these discrepancies can aid users in making informed decisions regarding which technology best fits their objectives.

3. INFLUENCE OF ENVIRONMENTAL CONDITIONS ON NO-LOAD VOLTAGE

Environmental conditions play a pivotal role in shaping the no-load voltage characteristics of solar panels. Temperature variations can dramatically influence the panel’s output. In colder environments, the no-load voltage may experience an uptick since cooler temperatures are less likely to cause thermal losses. Conversely, when the temperature rises, the voltage may decrease, thereby affecting performance and energy yield.

Another vital factor is irradiance, which pertains to the solar energy received on the panel’s surface. When irradiance levels peak, the voltage likewise reaches its zenith. Various environments, such as urban areas with shadowing from buildings or regions with frequent cloud cover, may experience significant fluctuations in irradiance. These changes will have direct implications on the voltage output during different times of the day and under various weather conditions.

4. IMPORTANCE OF NO-LOAD VOLTAGE IN SOLAR SYSTEM DESIGN

In the realm of solar energy systems, understanding no-load voltage assists in the meticulous design of these installations. This voltage parameter is particularly relevant for optimal system performance and compatibility with essential components, such as inverters and batteries.

For instance, inverters operate within specific voltage ranges to ensure efficient energy conversion from DC (direct current) to AC (alternating current). By understanding the no-load voltage output of solar panels, designers can specify inverters that effectively synchronize with the panel’s capabilities, thus maximizing energy conversion and minimizing wastage.

Additionally, in battery-based systems, understanding the no-load voltage is paramount for effective charging practices. A mismatch between the solar panel output and the battery’s voltage requirements can lead to inefficient charging and, potentially, battery damage. Therefore, meticulous planning guided by no-load voltage insights can significantly enhance the longevity and performance of energy systems.

5. NO-LOAD VOLTAGE MEASUREMENT TECHNIQUES

Accurately measuring no-load voltage should be approached with care and precision. Various instruments, such as multimeters, can be employed to gauge this parameter effectively. To initiate the measurement, it is vital to ensure that the solar panel is clean and free from debris or shading to obtain an accurate reading.

The measurement process involves connecting the multimeter’s positive and negative probes to the solar panel terminals. Once the probes are securely attached, the multimeter displays the voltage reading, representing the no-load condition. Proper attention should be paid to the conditions under which testing occurs—primarily, the time of day and environmental factors that may affect irradiance and temperature levels.

Regular measurement of no-load voltage is advisable for those operating solar energy systems, as it can provide insights into performance trends. Any significant deviations from expected values may denote underlying issues that warrant further investigation, such as degradation of panel materials or performance loss due to environmental impacts.

FREQUENTLY ASKED QUESTIONS

WHAT IS THE SIGNIFICANCE OF NO-LOAD VOLTAGE IN SOLAR PANELS?

The importance of no-load voltage in solar panels lies in its role in determining the maximum voltage the panel can supply under optimal conditions. It acts as a benchmark that informs system designers when selecting components like inverters and batteries to ensure compatibility and efficiency. If the voltage output is not adequately aligned with system requirements, it can lead to inefficiencies, excessive energy losses, or even damage to the components involved. Thus, grasping this concept becomes crucial for the overall effectiveness of solar energy systems, enabling effective energy capture, conversion, and storage.

HOW DOES TEMPERATURE AFFECT THE NO-LOAD VOLTAGE?

Temperature is a defining factor impacting the no-load voltage of solar panels. In cooler conditions, the electrical output tends to increase, often resulting in higher voltage readings, which is beneficial for energy generation. However, as temperature escalates, the no-load voltage can decline due to thermal effects impacting the semiconductor materials present in the panel. This decrease can translate to diminished efficiency and overall output. Therefore, it is essential to account for local climate conditions when evaluating solar panel performance and capabilities to optimize energy production.

WHAT DIFFERENCE DOES IRRADIANCE MAKE TO NO-LOAD VOLTAGE?

Irradiance, referring to the power of sunlight received per unit area, is another crucial variable influencing no-load voltage. In essence, when irradiance levels rise, the potential voltage output from a solar panel increases, resulting in enhanced energy generation capacity. Conversely, under low-irradiance circumstances—such as cloudy days or shaded environments—the no-load voltage will be lower. This relationship highlights the necessity for system design considerations that take into account varying irradiance levels throughout the year, ensuring that installations can adapt and optimize performance based on external sunlight availability.

The landscape of solar technology continues to evolve, making understanding no-load voltage pivotal in maximizing solar system performance. Solar panels serve as essential components harnessing the sun’s energy, transitioning it into usable electrical power. The nuances surrounding no-load voltage cannot be overstated; it is fundamentally tied to the overall design, efficiency, and effectiveness of solar installations. Awareness of how this voltage influences system components leads to informed decisions, contributing to increased energy yield and overall sustainability.

By maintaining a clear focus on factors such as temperature, irradiance, and the implications of choosing the right panel technology, stakeholders can appropriately navigate the complexities of solar energy systems. Moreover, monitoring and measuring no-load voltage regularly can pave the way for preemptive maintenance, ultimately prolonging the lifespan and efficiency of solar panel setups.

Furthermore, as the solar industry advances, the importance of no-load voltage will likely remain a focal point for innovation and improvement. Embracing new technologies and methods to enhance performance will continue driving forward the efficiency of solar energy systems. Sustainable energy solutions are not just a trend; they represent the future, securing both economic and environmental benefits for generations to come. Understanding and optimizing no-load voltage will undeniably play a crucial role in this journey.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-is-the-no-load-voltage-of-solar-panels/