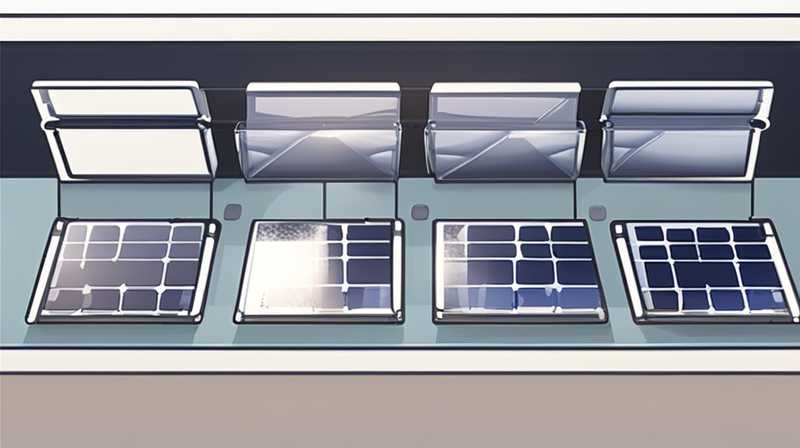

Solar silicon panels are primarily composed of silicon, a key element in the production of photovoltaic cells. 1. The main types of silicon used in solar panels are monocrystalline, polycrystalline, and amorphous silicon. 2. Monocrystalline silicon is known for its high efficiency and longevity, whereas polycrystalline silicon is more cost-effective but slightly less efficient. 3. Amorphous silicon, utilized in thin-film technology, offers flexibility and lightweight advantages but generally has lower efficiency rates. 4. Overall, the choice of silicon type affects the panel’s performance, production costs, and application suitability. Monocrystalline panels, with their single-crystal structure, typically provide the highest energy conversion efficiency and take up less space, making them ideal for residential and commercial installations with limited roof space. On the other hand, polycrystalline panels, comprised of multiple silicon crystals, represent a balance between affordability and performance, finding extensive use in larger utility-scale projects. The various forms of silicon and their characteristics allow for the development of solar technologies suited to different energy needs and economic considerations, ensuring accessibility to solar energy solutions for a diverse range of applications.

1. THE CHEMICAL STRUCTURE OF SILICON

Silicon is classified as a metalloid and possesses unique properties that render it an ideal component for solar energy collection. Its atomic structure features four valence electrons, enabling extensive bonding capabilities with other atoms, particularly oxygen. This tetravalent nature allows silicon to form a robust crystal lattice, essential for creating silicon wafers in photovoltaic cells. Monocrystalline and polycrystalline varieties differ primarily in their formation processes. Monocrystalline silicon is produced from a single crystal lattice structure, which is grown in a controlled environment. The manufacturing process results in higher purity and fewer defects, significantly elevating its energy conversion efficiency.

In contrast, polycrystalline silicon is manufactured from multiple silicon crystals melted together. This method incurs a lower cost due to less stringent production requirements, yet it introduces certain inconsistencies in the crystal structure. Consequently, polysilicon panels generally exhibit lower efficiency rates compared to their monocrystalline counterparts. Despite their lower efficiency, polycrystalline panels are commonly utilized in large-scale solar farms due to cost considerations and decent performance.

2. TYPES OF SILICON AND THEIR CHARACTERISTICS

The varieties of silicon utilized in solar panel production showcase distinctive characteristics that cater to diverse energy needs. Monocrystalline silicon, recognized for its smooth and uniform appearance, boasts the highest efficiency ratings, often exceeding 20%. Its energy production capabilities, particularly in low-light conditions, make it a favored choice for urban environments where rooftop space is limited. The longevity of monocrystalline panels, typically supported by warranties of 25 years or more, further enhances their appeal to consumers seeking long-term investments.

Polycrystalline silicon presents a more affordable option, although with trade-offs. While efficiencies range from 15% to 20%, often lagging behind monocrystalline options, polycrystalline panels benefit from a lower manufacturing cost, which translates to more accessible pricing for large installations. Their physical appearance, often characterized by a speckled look due to the cooling process of multiple silicon crystals, does not diminish their functionality in solar farm applications. Notably, advancements in manufacturing techniques are continually improving the efficiency rates of polycrystalline panels, allowing them to remain competitive.

Amorphous silicon, distinct from crystalline forms, offers unique advantages as a thin-film option. The lack of a crystalline structure results in flexibility and lightweight properties, enabling applications where traditional panels would be impractical. These characteristics make amorphous silicon a suitable choice for building-integrated photovoltaics (BIPV) and portable solar devices. However, the efficiency of amorphous silicon usually hovers around 6% to 10%, which limits its use in energy-hungry applications. Innovations aimed at enhancing the performance of thin-film technology promise to extend its reach within the solar sector.

3. MANUFACTURING PROCESSES OF SILICON PANELS

Producing solar panels requires a meticulous and often complex manufacturing process that transforms raw silicon into functional photovoltaic cells. The first stage involves purifying silicon, attained through a chemical process that removes impurities and results in metallurgical-grade silicon. For the production of monocrystalline panels, this purified silicon undergoes crystal growth techniques, such as the Czochralski method or the Float Zone method, which yield high-purity single crystal wafers. These wafers are subsequently sliced into thin discs, cleaned, and subjected to doping processes, where elements like phosphorus or boron are introduced to create p-type or n-type semiconductors that facilitate the flow of electrical current.

Polycrystalline silicon production diverges significantly from monocrystalline methods. Instead of individual crystal growth, polycrystalline silicon begins by melting purified silicon and allowing it to cool in molds. The result is a large block of silicon comprising various interconnected crystals, which is then cut into wafers for further processing. This approach is more economically feasible, particularly for large-scale installations, but leads to some inherent inefficiencies due to the multi-crystal structure. Once the wafers from both types undergo doping, they proceed to be coated with anti-reflective layers that enhance light absorption.

The final stages of production involve assembling the wafers into solar cells, which are then interconnected and encapsulated in protective materials to ensure longevity. This encapsulation safeguards against moisture, temperature fluctuations, and environmental wear, ensuring that solar panels maintain their performance over time. The rigorous quality checks during manufacturing, including electrical testing and visual inspections, are critical to delivering reliable and efficient solar panels to market.

4. PERFORMANCE AND EFFICIENCY COMPARISONS

A fundamental aspect of any photovoltaic technology involves assessing efficiency metrics and performance in real-world applications. Monocrystalline panels are distinguished as the most efficient types, exhibiting superior capabilities for energy conversion under standard test conditions. This inherent efficiency translates into higher energy output per square meter compared to other silicon technologies. During periods of lower sunlight, such as cloudy days, monocrystalline panels are still capable of producing energy more effectively, making them well-suited for regions with less consistent solar exposure.

In contrast, polycrystalline panels often yield lower efficiency rates, particularly in tight spaces or specific orientations. While their performance can still be robust, those utilizing polycrystalline technology may need to invest in larger installations to achieve similar output levels as monocrystalline setups. Interestingly, advancements in manufacturing and material science are gradually narrowing these performance gaps, enabling polycrystalline solutions to maintain a competitive edge.

Moreover, environmental considerations play a significant role in the performance discourse surrounding solar panels. Amorphous silicon’s lower efficiency is compensated by its lower environmental footprint during manufacture, as less material is required compared to crystalline counterparts. The lightweight nature of thin-film technology can also lessen structural load requirements for rooftops and installations. However, it is crucial to assess how these trade-offs impact overall life-cycle energy production and contribute to sustainable energy solutions.

5. COST ANALYSIS AND ECONOMIC IMPLICATIONS

The economic dynamics of solar silicon panels involve a complex interplay of manufacturing costs, installation expenses, and potential savings over time. Monocrystalline panels command higher initial investment, reflecting the costs associated with high-purity silicon and the intricate production processes involved. This upfront expense may deter some consumers; however, many perceive the enhanced efficiency, durability, and warranty periods as valuable long-term benefits.

Conversely, polycrystalline panels position themselves as more accessible in terms of affordability. The reduction in production costs, alongside competitive performance, enables consumers on a budget to opt for solar solutions without compromising too much on efficiency. This economic advantage becomes even more pronounced in utility-scale solar farms, where larger quantities can be procured at lower costs per watt installed, leading to substantial energy production savings.

In recent years, government incentives, rebates, and advancements in financing options have contributed to a broader adoption of solar technologies across consumer sectors. As economies of scale develop, manufacturers can achieve cost reductions, further enhancing the attractiveness of solar investments. Ultimately, the choice of panel type is influenced by economic considerations intertwined with personal energy goals, environmental preferences, and space availability.

6. ENVIRONMENTAL IMPACT AND SUSTAINABILITY

Solar power generation is heralded for its environmental benefits, particularly in reducing greenhouse gas emissions and dependence on fossil fuels. The material selection for solar silicon panels critically impacts their overall ecological footprint. Monocrystalline silicon, while efficient, presents challenges during its production stages, where energy-intensive processes may generate significant carbon emissions. In contrast, advancements in solar manufacturing technologies, particularly in reducing energy consumption and increasing material recycling, aim to lessen these environmental burdens.

Furthermore, the life-cycle assessment of silicon panels reveals insights into their sustainability credentials. Although polycrystalline panels carry a smaller carbon footprint during production, their overall life cycle performance can vary based on materials used, local recycling capabilities, and installation impacts. Innovations in photovoltaic recycling are fostering circular economy practices within the solar industry. By developing processes to recover and reuse materials from decommissioned solar panels, the environmental implications of both types of silicon can be substantially offset.

Engaging with the ecological component of solar energy solutions prompts broader discussions surrounding energy justice, equitable access, and environmental protection. Stakeholders, including manufacturers, policymakers, and consumers, must collaborate to promote ethical practices, ensuring that the benefits of solar technologies are shared across communities while preserving the integrity of natural resources.

QUESTIONS THAT OFTEN ARISE

WHAT IS THE LIFESPAN OF SOLAR SILICON PANELS?

Solar silicon panels generally have a lifespan of 25 to 30 years, but this can vary based on several factors. Climate conditions, installation quality, and maintenance practices all play a significant role in determining how long solar panels will perform at optimal levels. Many manufacturers provide warranties extending up to 25 years, assuring that their products will generate a specified level of power during this period. However, panels can continue to produce electricity after this timeframe, although at reduced efficiency. Regular maintenance and periodic assessments can help ensure that solar panels operate effectively throughout their lifespan, thus maximizing return on investment and energy yield.

HOW DO CLIMATE CONDITIONS AFFECT SILICON PANEL PERFORMANCE?

Climate conditions significantly influence the performance of solar silicon panels. Panels are designed to operate under various environmental factors, including temperature, sunlight exposure, humidity, and seasonal variations. High temperatures can potentially decrease the efficiency of solar panels, while excessive shading can obstruct energy production. Conversely, locations with ample sunlight and moderate climates often see optimal performance from both monocrystalline and polycrystalline technologies. However, advancements in design and manufacturing continue to improve the resilience and efficacy of panels in diverse conditions, ensuring reliable energy production even in challenging environments.

WHAT ADVANCEMENTS ARE BEING MADE IN SOLAR TECHNOLOGY?

Innovation plays a crucial role in the evolution of solar technology, focusing on improving efficiency, reducing costs, and enhancing product lifespan. Researchers are exploring new materials and manufacturing techniques, such as bifacial solar cells that capture sunlight from both sides and perovskite solar cells that promise higher efficiencies at lower costs. Moreover, enhancements in energy storage technologies, including advanced battery systems, allow for better management of solar energy production, overcoming intermittent supply challenges. Collaborative efforts within the industry continue to push the boundaries of solar technology, making renewable energy more accessible and effective across a global scale.

Solar silicon panels serve as a cornerstone in the renewable energy landscape, utilizing various forms of silicon—monocrystalline, polycrystalline, and amorphous—to harness solar energy efficiently. Each form comes with its advantages, impacting factors such as energy production, cost, and environmental commitment. Monocrystalline panels are celebrated for their efficiency and longevity, making them prime choices for installations where space is limited. In contrast, polycrystalline panels appeal to budget-conscious consumers while delivering satisfactory performance in larger projects. Amorphous silicon underscores the flexibility and lightweight nature of thin-film technology, broadening the applications for solar energy.

The manufacturing of these panels involves sophisticated processes, emphasizing purity, structure, and durability. Innovations in production methods are increasingly focused on reducing the environmental impact of solar technologies and improving sustainability. As the market for solar power continues expanding, understanding the intricate details behind solar silicon panels equips consumers and stakeholders with the knowledge to make informed decisions while optimizing energy solutions. Investing in solar panels is not merely a financial decision; it is a commitment to renewable energy, sustainability, and a collaborative approach to mitigating climate change and protecting our planet for future generations. The implications of selecting the right type of solar silicon technology extend beyond personal benefits, contributing to larger ecological solutions and energy independence.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-is-the-material-of-solar-silicon-panels/