Understanding the energy storage inductance of a direct current (DC) module is vital for enhancing efficiency and functionality in various electrical and electronic applications. 1. Energy storage inductance represents the ability of a module to store energy in an inductor; 2. This parameter is crucial for managing power delivery in electrical systems; 3. Inductance values influence circuit response and performance characteristics; 4. Knowledge of these values assists in optimizing designs for specific applications. In detail, inductance functions as a crucial component in energy storage systems, facilitating the conversion of energy between electrical and magnetic forms. Inductors in DC modules play a pivotal role in smoothing out voltage fluctuations and maintaining a consistent flow of current. High inductance values can store significant energy, allowing for better performance under varying load conditions and aiding in stability during transient responses, making it essential for designers and engineers to comprehend the intricacies involved.

1. DEFINITION AND IMPORTANCE OF ENERGY STORAGE INDUCTANCE

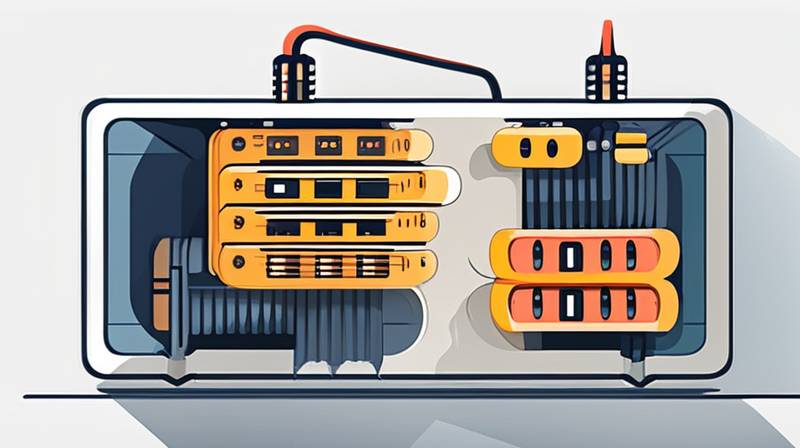

Understanding energy storage inductance begins with recognizing its fundamental definition. Inductance is a measure of an inductor’s capacity to store energy in its magnetic field when an electric current passes through it. This process is governed by the relationship between voltage, current, and the physical characteristics of the inductor, such as the number of coil turns, the core material, and the shape of the inductor.

The significance of energy storage inductance cannot be understated. In DC modules, inductance is crucial for ensuring efficient energy transfer and maintaining circuit stability. When designs incorporate adequate inductance, it allows for smoother power delivery and can effectively mitigate voltage spikes, reducing stress on other components. Furthermore, increased inductance leads to enhanced performance during load changes, making the system more resilient against fluctuations.

2. METRICS AND CALCULATIONS OF INDUCTANCE

Calculating inductance in the context of energy storage involves several parameters. The formula for inductance (L) is defined as L = V / (di/dt), where V represents voltage, di represents the change in current, and dt is the change in time. This formula enables engineers and designers to determine the required inductance values necessary to achieve desired performance levels in direct current systems.

Moreover, the inductance value is often influenced by the core material utilized. Inductors constructed with ferromagnetic materials tend to possess higher inductance values compared to air-core inductors, leading to enhanced energy storage capabilities. Understanding the role of different core materials becomes vital in optimizing the design for specific energy storage requirements. By manipulating these design parameters, engineers can tailor the inductance characteristics to achieve specific performance objectives, tapping into the intrinsic properties of the materials used.

3. APPLICATIONS IN ELECTRICAL AND ELECTRONIC SYSTEMS

Energy storage inductance finds varied applications across numerous electrical and electronic systems. One notable application includes power supply circuits, where inductance assists in voltage regulation and ripple reduction. In such setups, a well-designed inductor can store energy during periods of high demand and release it during lulls, maintaining a steady voltage output.

Another critical application encompasses renewable energy systems, particularly in solar inverters. These devices rely on energy storage inductance to manage fluctuations in power generation due to variable sunlight conditions. In this context, the inductors are central to optimizing energy capture and conversion efficiency, ensuring dependable power output while accommodating changing environmental conditions.

4. IMPACT OF INDUCTANCE ON SYSTEM PERFORMANCE

The influence of inductance on the overall performance of a DC module is multifaceted. Higher inductance generally leads to improved energy storage, enhancing the system’s ability to handle peak loads and dynamic conditions. More specifically, an increased ability to manage sudden changes in current can reduce the risk of voltage spikes, thereby protecting sensitive components within the circuit.

However, it is essential to strike a balance. Excessively high inductance can lead to slower response times and impede dynamic performance in fast-switching applications. Therefore, selecting the appropriate inductance value is critical. Engineers must analyze the specific requirements of their applications, considering factors such as load characteristics, expected current variations, and required response times, culminating in a well-rounded approach to energy storage inductance design.

5. ADVANCED TECHNIQUES FOR OPTIMIZING INDUCTANCE

Beyond understanding basic inductance principles, engineers are implementing advanced techniques to enhance the effectiveness of energy storage inductance in DC modules. One innovative approach involves employing coupled inductors, which can increase efficiency by allowing multiple inductors to share energy storage capabilities. This method ensures that the energy gathered during high load situations can be instantly redirected to where it is most needed, thus improving overall system responsiveness.

Additionally, designers are increasingly utilizing digital simulation tools that model inductance effects under various operational scenarios. By simulating different configurations and evaluating performance outcomes, engineers can optimize the inductor design before physical implementation. These simulation tools become invaluable resources, enabling precise tuning of energy storage parameters and better accommodating unique project demands.

FREQUENTLY ASKED QUESTIONS

WHAT FACTORS AFFECT ENERGY STORAGE INDUCTANCE?

Several aspects can influence the energy storage inductance of a system. Core material, the number of turns in the coil, and the physical geometry of the inductor are primary contributors. Inductors with ferromagnetic cores typically exhibit significantly higher inductance compared to air-core options due to enhanced magnetic flux concentration. Additionally, the winding technique and the spacing of the coils may affect the inductance value, emphasizing the importance of each design element in the energy storage configuration. External conditions such as temperature and frequency also play a role, as they can impact material properties and performance metrics, signifying the need for comprehensive analysis during the design phase.

HOW DOES INDUCTANCE IMPACT POWER SUPPLY CIRCUITS?

Inductance plays a crucial role in power supply circuits, primarily in regulating voltage levels. In such systems, inductance assists in smoothing variations in current demand, allowing for consistent voltage output. When the load on the circuit fluctuates, inductors store excess energy during periods of high demand and release it during down times, thus stabilizing the overall performance. Furthermore, by reducing voltage ripple, inductors help protect downstream components from damage caused by voltage spikes. Ultimately, an optimal inductance value is vital, enabling reliable performance and longevity within power supply designs.

HOW CAN I SELECT THE RIGHT INDUCTANCE FOR MY APPLICATION?

Choosing the appropriate inductance value involves a comprehensive assessment of the system requirements. Key factors to consider include the voltage and current ratings, load characteristics, and frequency of operation. Typically, beginning with a detailed analysis of system performance needs allows for preliminary calculations of inductance values based on empirical formulas. Ensuring consideration of peak load conditions and potential transient responses provides additional layers of redundancy in the decision-making process. In many cases, iterative prototyping coupled with performance evaluation becomes necessary, allowing engineers to fine-tune their inductance choices for optimal results.

Understanding the intricacies of energy storage inductance in DC modules necessitates a deep exploration of its definition, applications, and implications. The various aspects include how inductance features in system performance, the significance of materials and configurations, and advanced optimization techniques designed to enhance functionality. Additionally, engaging with common queries surrounding inductance can elucidate important considerations for current and future applications. As electricity and power generation systems evolve, the role of energy storage inductance will remain central, influencing everything from renewable energy processes to efficient circuit design. Ultimately, engineers and designers must maintain an up-to-date understanding of inductance characteristics and their relevance in a rapidly advancing technological landscape, ensuring that they can adapt practices accordingly. In an era driven by innovative solutions, knowledge of such foundational principles will be imperative for cultivating effective and efficient electrical systems.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-is-the-energy-storage-inductance-of-the-dc-module/