What is the energy storage device assembly?

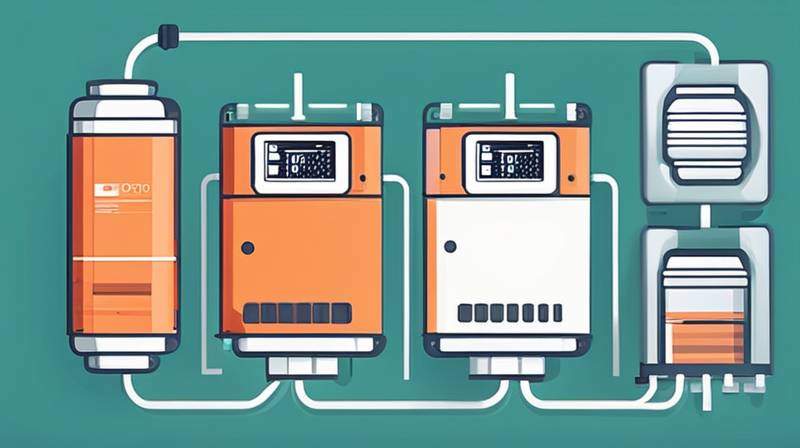

1. Energy storage devices are critical components used to capture, hold, and release energy as required. 2. These assemblies can include batteries, capacitors, ultra-capacitors, and flywheels, among others. 3. The assembly process involves integrating various components to ensure they function efficiently. 4. Understanding the interplay between different energy storage technologies is vital for optimizing performance and ensuring longevity. Elaborating further, energy storage device assemblies serve as essential elements in a range of applications, from renewable energy systems to electric vehicles and grid stability. The successful assembly of these devices requires a thorough understanding of electrochemistry, mechanical engineering, and materials science.

1. UNDERSTANDING ENERGY STORAGE DEVICES

The significance of energy storage devices in modern society cannot be overstated. As the global energy landscape shifts towards greater reliance on renewable sources, the need for efficient energy management systems becomes crucial. Energy storage devices are designed to mitigate the intermittent nature of solar and wind power, enabling a more stable and reliable energy supply.

In essence, energy storage systems allow for energy to be stored during times of low demand and released during peak demand periods. This characteristic makes them indispensable in achieving energy efficiency and sustainability goals. Notably, the assembly of these devices requires a combination of various components that must be meticulously integrated to ensure optimal performance. By understanding how these systems function, stakeholders can better appreciate the role they play in contemporary energy solutions.

2. COMPONENTS OF ENERGY STORAGE ASSEMBLIES

To comprehend the assembly of energy storage devices, it is essential to identify the primary components involved in their construction. Batteries are typically composed of an anode, cathode, electrolyte, and separator. These elements work together to facilitate the electrochemical reactions necessary for energy storage and release.

Capacitors, on the other hand, store energy through an electric field created between two conductive plates separated by an insulating material. Ultra-capacitors combine the principles of batteries and capacitors, allowing for rapid energy release and absorption. The choice of components heavily influences the overall efficacy and capacity of the energy storage assembly, making it imperative to select the most suitable materials for the intended application.

Furthermore, developments in battery technology—such as lithium-ion, solid-state, and flow batteries—highlight the importance of ongoing research in the field. Each of these battery types offers distinct advantages and challenges, necessitating careful consideration when assembling energy storage solutions.

3. ASSEMBLY PROCESS OF ENERGY STORAGE DEVICE

The assembly process for energy storage devices is multifaceted, requiring precision and expertise at every stage. Initially, careful attention must be paid to sourcing quality materials, as the performance and lifespan of the device hinge on component integrity. This begins with the selection of electrodes and electrolytes that possess optimal electrochemical properties.

Following material acquisition, the assembly stage involves several procedures, including electrode preparation, electrolyte filling, and cell stacking in the case of multi-cell configurations. Each step is critical to ensure that the device operates at peak efficiency. For batteries, this may also include the encapsulation of cells to protect them from environmental factors, as well as the integration of battery management systems to monitor performance and safety during operation.

Quality control plays a pivotal role throughout the assembly process. Rigorous testing must be conducted at various stages to assess not only the functionality of individual components but also the performance of the assembled device as a whole. Maintaining high manufacturing standards is essential to minimize defects and optimize reliability in energy storage assemblies.

4. MAINTENANCE AND LONGEVITY OF ENERGY STORAGE ASSEMBLIES

To ensure that energy storage devices maintain optimal performance over their lifespan, regular maintenance is crucial. For example, batteries require periodic checks to monitor charge cycles and battery health, helping to prevent issues related to aging and degradation. Understanding the specific characteristics of various types of batteries can inform appropriate maintenance strategies, thus prolonging their life and efficacy. Similarly, capacitors must be assessed for leakage and capacitance values, as both factors impact their ability to store and release energy efficiently.

Another significant aspect of extending the life of energy storage assemblies involves operating conditions. Temperature, humidity, and load conditions can dramatically affect performance and longevity. Implementing safeguards and monitoring systems can help mitigate adverse conditions, ultimately enhancing the durability of the assembly. Furthermore, advancements in technology are continuously reshaping maintenance protocols, enabling predictive analytics to foresee potential failures before they occur.

With increasing adoption of renewable energy sources and electric vehicles, the demand for reliable energy storage solutions is set to rise even further in the coming years. Industry players must prioritize not only the assembly and initial quality of devices but also their long-term maintenance to maximize return on investment.

5. THE FUTURE OF ENERGY STORAGE ASSEMBLY TECHNOLOGIES

The landscape of energy storage technology is rapidly evolving, with innovative solutions emerging to address current limitations. One area of advancement involves solid-state batteries, which present improved energy density and enhanced safety features compared to traditional lithium-ion batteries. Their unique construction allows them to potentially surpass the performance of current technologies, making them a focal point of research and development in energy storage assembly.

Moreover, flow batteries are gaining traction owing to their scalability and long cycle life, particularly suited for large-scale energy storage applications. These systems allow for greater flexibility in energy management, accommodating varying power requirements with ease. Emphasizing the importance of recycling and sustainability in energy storage development is also crucial, as manufacturers strive to minimize the environmental impact associated with device assembly and disposal.

As the world strives to achieve climate targets and reduce reliance on fossil fuels, the role of energy storage assemblies becomes increasingly vital. Continuous innovation and collaboration across industries will be essential in driving advancements and ensuring that our energy systems remain resilient, efficient, and sustainable.

FREQUENTLY ASKED QUESTIONS

WHAT TYPES OF ENERGY STORAGE DEVICES EXIST?

There are various types of energy storage technologies, each designed to serve specific needs and applications. Batteries are perhaps the most well-known for storing electrical energy chemically, with lithium-ion batteries being predominant in consumer electronics and electric vehicles. Capacitors, which store energy electrostatically, have applications in power backup and electronic devices. Ultra-capacitors combine the benefits of both batteries and capacitors, able to retain energy and deliver it quickly, making them suitable for applications requiring immediate power bursts. Other advanced technologies, such as flywheels, utilize kinetic energy and are primarily employed in grid stability and frequency regulation. Understanding the unique characteristics and applicable scenarios for each technology is imperative for choosing the right energy storage solution.

HOW DOES THE ASSEMBLY PROCESS AFFECT DEVICE PERFORMANCE?

The assembly process of energy storage devices plays a pivotal role in determining their reliability, efficiency, and overall performance. Each assembly step— from material selection to quality control— significantly impacts operational outcomes. If components are not integrated properly or quality standards are neglected, the risks of performance issues or outright failure increase markedly. For instance, precise electrode alignment and proper electrolyte filling are crucial in battery assembly; any error can result in decreased energy capacity or accelerated wear. Moreover, emphasizes on thorough testing throughout the assembly process, identifying potential failure points early on, is critical for optimizing the final product. By understanding the importance of meticulous assembly practices, manufacturers can ensure that their devices meet or exceed industry standards.

WHAT IS THE SIGNIFICANCE OF ENERGY STORAGE ASSEMBLY IN RENEWABLE ENERGY SYSTEMS?

Energy storage assembly is paramount for the successful integration of renewable energy sources such as solar and wind power into the grid. These energy sources rely on varying environmental conditions and often produce energy intermittently, leading to challenges in maintaining a stable energy supply. Energy storage systems mitigate these fluctuations by capturing excess energy during peak production times and releasing it during periods of high demand or low generation. The assembly of efficient energy storage devices is crucial to respond swiftly to changes in supply and demand, ensuring grid stability and reliability. Furthermore, energy storage plays a vital role in supporting the transition to clean energy, as it allows for the maximization of renewable resource utilization, thereby contributing to sustainability goals.

BOLDNESS IN REINFORCING THE NECESSITY OF ENERGY STORAGE DEVICE ASSEMBLY

The assembly of energy storage devices is undeniably foundational to harnessing the full potential of modern energy solutions. Given the intricate interplay of components involved, expertise and attention to detail are indispensable throughout the assembly process. The advantages offered by well-assembled energy storage systems extend beyond mere functionality; they encompass safety, reliability, and efficiency. As industries continue to embrace renewable energy technologies, the demand for high-quality energy storage systems will only intensify.

Moreover, advancements in battery technology, the integration of innovative materials, and the optimization of assembly processes will collectively shape the future landscape of energy storage. The importance of a comprehensive approach cannot be overstated; from meticulous design to diligent maintenance, every aspect contributes to the device’s overall longevity and performance. As we navigate towards a more sustainable energy future, a robust understanding of energy storage device assembly and its implications will play a crucial role in enabling energy independence and environmental stewardship.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-is-the-energy-storage-device-assembly/