Polycrystalline solar panels display several distinctions when compared to other types, notably in manufacturing processes, efficiency, cost, and appearance. 1. Manufacturing Process: Polycrystalline panels are composed of multiple silicon crystals and are produced by melting silicon fragments together. This method differs from monocrystalline panels, which utilize a single silicon crystal. 2. Efficiency: Generally, polycrystalline panels tend to have a lower efficiency rate, typically around 15-20%, when set against monocrystalline panels, which can reach efficiencies over 20%. 3. Cost: On the financial side, polycrystalline options often present a more budget-friendly alternative, making them appealing for larger projects where cost is a critical factor. 4. Appearance: Visually, they appear bluish and have a speckled, non-uniform surface as a result of varying crystal structures. These fundamental aspects influence consumer choices, installer preferences, and market trends. For those considering solar energy solutions, understanding these differences helps in making informed decisions and maximizing energy investments.

1. MANUFACTURING PROCESS

The creation of polycrystalline solar panels involves a specific methodology that distinguishes them from their monocrystalline counterparts. This process starts with purification of silicon, followed by the melting of silicon fragments together to form multiple crystals. The resulting material is then cooled and sliced into thin wafers that make up the solar cells. This technique is relatively more cost-effective, contributing to lower manufacturing expenses. The lesser purity of silicon in this method, however, translates into decreased efficiency. As these panels have no distinct single silicon structure, their performance in energy conversion tends to be less optimal.

In contrast, monocrystalline panels excel in efficiency due to their single-crystal structure. They undergo a more complex manufacturing process, where purified silicon forms a single continuous crystal. This increased purity provides them with the advantages of higher efficiency ratings, often exceeding 20%, as they facilitate better electron mobility. The disparity in production techniques between the two types results in significant differences in their respective performance metrics and market positioning.

2. EFFICIENCY

The efficiency of solar panels is a critical factor when assessing their performance and suitability for various applications. Polycrystalline solar panels generally operate at an efficiency ranging between 15-20%. This is primarily because of their multiple crystal structure and less optimal energy conversion processes. The presence of various silicon crystals introduces more boundaries for electrons to traverse, thereby causing increased resistance and energy loss. Consequently, while polycrystalline solar panels are cost-effective, they may necessitate a larger surface area to generate the same amount of power as more efficient alternatives.

In comparison, monocrystalline panels, known for their single-crystal structure, achieve higher efficiency levels. Due to their uniform crystal lattice, these panels can convert sunlight into electricity more effectively, resulting in more power output from a given area. This higher efficiency makes monocrystalline panels particularly suitable for installations where space is at a premium. Thus, while polycrystalline panels might serve well in large-scale applications where budget constraints exist, stakeholders must weigh these benefits against the overall output and efficiency when making their choices.

3. COST

When evaluating solar panel types, financial implications often play a decisive role. Polycrystalline solar panels are generally more affordable to produce, leading to lower market prices. The reduced cost associated with their manufacturing process makes them attractive for large-scale energy installations where financial limitations are prevalent, like commercial solar farms or residential systems aiming for a lower initial expenditure. Despite their lower upfront costs, consumers should be mindful of potential long-term performance deficits due to the relative inefficiency of these panels, resulting in potentially higher overall energy costs over time.

Conversely, while monocrystalline solar panels come with a higher price tag, their exceptional efficiency ratings can result in a faster return on investment. Over time, the increased energy production from these panels reduces energy bills significantly, sometimes compensating for the initial expenses. Therefore, the financial evaluation becomes essential in selecting solar panels—considerations extend beyond initial costs to encompass potential savings and energy outputs in the long run. Stakeholders should conduct comprehensive calculations to estimate the overall value generated through either option.

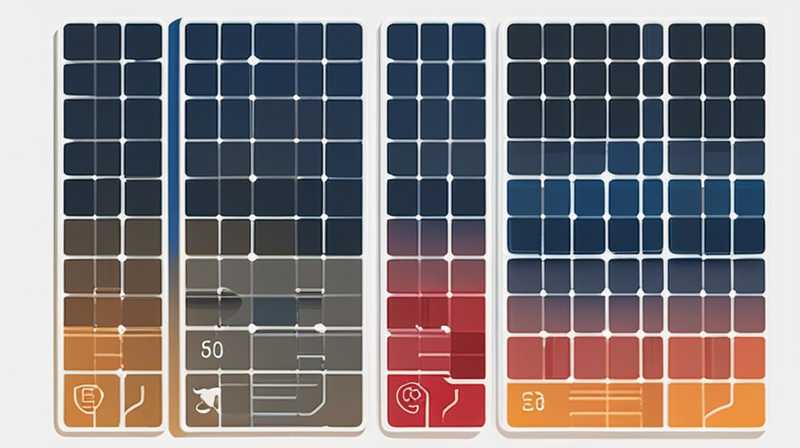

4. APPEARANCE

The visual characteristics of polycrystalline solar panels set them apart in the market. Typically, these panels exhibit a bluish tint and showcase a textured, speckled surface due to the multiple crystal structures that compose them. This distinct appearance results from the random arrangement of silicon crystals, creating a unique aesthetic that differs from monocrystalline panels, which are often uniform and black in hue. The non-uniform look might appeal to certain consumers but could also deter those seeking a more streamlined appearance for their solar installations.

Monocrystalline panels, in contrast, boast a sleek and polished look that many homeowners find visually appealing. Their uniform coloration contributes to a more integrated look when mounted on rooftops, making them a preferred choice for those prioritizing aesthetics alongside efficiency. The visual distinctions can influence consumer choice, particularly in residential applications where the appearance of solar panels plays a crucial role in overall satisfaction. Ultimately, considerations regarding appearance should complement other dominate factors like efficiency and cost in the decision-making process.

FAQs

HOW LONG DO POLYCRYSTALLINE SOLAR PANELS LAST?

Polycrystalline solar panels typically have a lifespan of around 25 to 30 years. Many manufacturers guarantee performance for at least 25 years, assuring consumers that their investment will last through the warranty period. Over time, the efficiency of the panels may decrease, usually by about 0.5-1% annually. This gradual decline in efficiency can be attributed to factors such as weather conditions, exposure to UV light, and other environmental elements. Regular maintenance, including cleaning and inspections, can maximize longevity and efficiency.

Investors should also consider that while polycrystalline panels may have a shorter lifespan compared to monocrystalline options, advancements in technology and materials are continually improving durability and lifespan across all solar panels. Moreover, several manufacturers are now offering improved warranties and protection policies, enhancing their attractiveness. Consequently, while longevity varies, polycrystalline panels represent a solid investment in the renewable energy landscape.

WHAT ARE THE ADVANTAGES OF POLYCRYSTALLINE SOLAR PANELS?

Several advantages make polycrystalline solar panels a favorable option in the solar energy market. Affordability is a significant advantage, as their manufacturing process is simpler and less costly than that of monocrystalline panels, leading to lower prices for consumers. This economic benefit allows homeowners and businesses with budget constraints to invest in solar technology.

Another noteworthy aspect is resilience in various weather conditions. Polycrystalline panels can perform well in cloudy or shaded environments, although their efficiency remains variable. Additionally, as their material consists of multiple silicon crystals, their resistance to overheating boosts overall performance during hot weather. Furthermore, the manufacturing process of polycrystalline panels typically has a lower environmental impact, given that it utilizes lower-grade silicon. This sustainability facet resonates with eco-conscious consumers aiming for a minimal carbon footprint. Thus, these panels provide attractive benefits for those focusing on cost, performance, and environmental considerations.

CAN POLYCRYSTALLINE PANELS BE INSTALLED IN COLD WEATHER?

Yes, polycrystalline panels can indeed be installed and perform adequately in cold weather conditions. Despite the common misconception that solar panels only work efficiently in warm temperatures, their functionality is not exclusively linked to heat. Cold weather conditions can enhance the efficiency of solar panels since the photovoltaic cells perform optimally when cool. In fact, the efficiency of polycrystalline panels can slightly increase in lower temperatures, helping to produce more electricity on clear sunny days during winter months.

However, it is crucial to ensure proper installation for optimal performance in cold climates. Factors such as snow accumulation can potentially obstruct sunlight exposure, thereby decreasing energy generation. To address this, installations may need specific considerations, including angle adjustments and ensuring regular maintenance to clear snow. While cold weather can present challenges, the inherent design of polycrystalline panels, combined with proper attention to their installation, allows for effective energy production throughout the winter.

In summary, distinguishing between polycrystalline and other types of solar panels requires an understanding of their fundamental differences, which encompass manufacturing processes, efficiency rates, cost implications, and visual characteristics. Each factor plays a vital role in informing consumer choices and shaping the solar energy landscape. Although polycrystalline panels are generally more affordable, their overall performance is often less than that of monocrystalline panels. Decision-making should prioritize long-term benefits and personal energy goals. As technology evolves, ongoing innovations in the solar industry may bring further advancements, making the consideration of solar energy an ever-important subject in the realm of sustainable energy solutions. Those interested in adopting solar technology should carefully weigh their options while assessing both immediate needs and future energy requirements in this rapidly advancing field.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-is-the-difference-between-polycrystalline-solar-panels/