What is the capacity of the hydraulic energy storage tank?

The capacity of a hydraulic energy storage tank is determined by various factors, including 1. the physical dimensions of the tank, 2. the operating pressure, and 3. the required energy output. A comprehensive understanding of these elements is crucial for optimizing the performance and efficiency of such systems. The physical size impacts the volume of fluid that can be stored, while the operating pressure influences how much energy can be stored and released efficiently. Additionally, having a clear assessment of the required energy output helps in designing a system that meets specific operational demands.

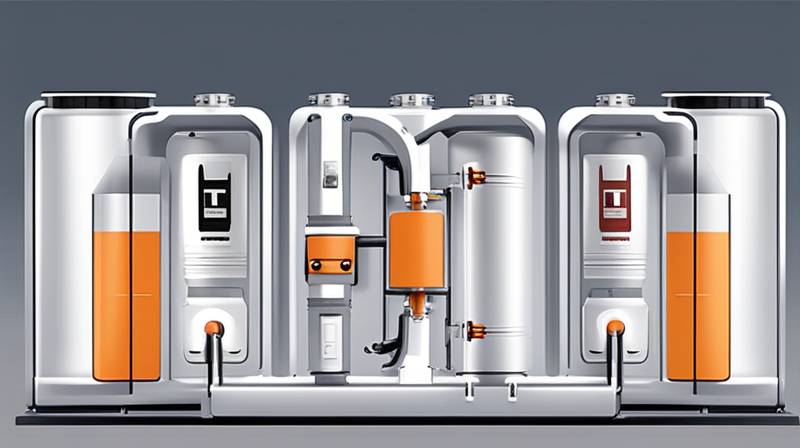

1. THE SIGNIFICANCE OF HYDRAULIC ENERGY STORAGE TANKS

Hydraulic energy storage tanks play a pivotal role in modern energy systems, particularly in the context of renewable energy sources. As the world moves toward sustainability, the demand for energy storage solutions has skyrocketed. These tanks serve to balance energy supply and demand, smooth out the intermittency associated with renewables like wind and solar energy, and facilitate grid stability. The design and capacity of a hydraulic energy storage tank can dramatically influence energy management strategies.

Often overlooked, the capacity of these tanks can dictate the overall efficiency of the energy storage system. When properly sized, they allow for greater energy storage potential, enabling utilities and businesses to harness renewable energy more effectively. Furthermore, the ability to store energy during off-peak hours and release it during peak demands aids in reducing reliance on fossil fuels. As a result, these tanks are crucial for monitoring and managing vast energy flows, enhancing the sustainability of energy consumption.

2. DESIGN CONSIDERATIONS FOR HYDRAULIC ENERGY STORAGE TANKS

When embarking on a design for a hydraulic energy storage tank, specific criteria must be evaluated to ensure that the system meets operational requirements effectively. First, the tank’s dimensions must align with the projected energy needs and the physical constraints of the installation site. Engineers must take into account factors such as the height and diameter of the tank, which play an essential role in determining its volume and structural integrity.

In addition to spatial considerations, the material selection is critical in reaching optimal performance levels. The internal composition of the tank must be resistant to corrosion and capable of withstanding high-pressure scenarios. Manufacturers often leverage advanced materials that provide durability and efficiency while minimizing maintenance costs. The design must also integrate suitable safety mechanisms to prevent failures, such as pressure relief valves and proper sealing to accommodate varying pressure levels. When these factors are meticulously addressed, the operational capacity of the tank can be maximized, ensuring reliability and longevity.

3. CAPACITY DETERMINATION METHODS

Determining the capacity of a hydraulic energy storage tank is an integrative process involving various methodologies. Engineers typically use formulas to calculate the volume required for a specific energy output based on water density and pressure levels. The basic formula for determining storage capacity can be expressed as the product of the tank’s volume and the density of the fluid used.

For instance, if the objective is to store a specific amount of energy, engineers translate that energy requirement into hydraulic parameters. By utilizing the potential energy formula ( E = mgh ), where ( m ) is mass, ( g ) is acceleration due to gravity, and ( h ) represents height, designers can ascertain how much water (or other fluids) needs to be stored under various pressure scenarios. This critical analysis supports the optimal design tailored to specific project needs.

Moreover, simulation models can help assess tank behavior under diverse operational scenarios, providing insights into how different capacities affect overall performance. Those simulations can accommodate variations in demand, discharge rates, and system efficiency, ensuring that the designed capacity meets or exceeds the anticipated operational expectations.

4. PERFORMANCE EVALUATION OF HYDRAULIC ENERGY STORAGE SYSTEMS

Performance evaluation is a vital part of any hydraulic energy storage system. Key performance indicators (KPIs) such as efficiency, response time, and storage duration must be analyzed comprehensively. Efficiency, for example, reflects how much energy put into the system can be retrieved during discharge. A high efficiency rate indicates that the hydraulic storage tank operates effectively, minimizing energy losses.

Additionally, response time relates to how quickly the system can deliver stored energy back to the grid or a specific application when needed. A faster response translates to a more responsive energy management system, vital for balancing supply and demand in real time. The duration of storage is another significant measure, as it reflects how long energy can be effectively stored before it needs to be converted or used.

Testing under various conditions establishes baseline performance metrics. This allows engineers and operators to adjust parameters, improve the design, and enhance the overall efficiency of the hydraulic energy storage tank system. By conducting deliberate performance assessments, developers can optimize each component, including the tank’s capacity, to meet the evolving demands of future energy systems.

5. ECONOMIC FACTORS IMPACTING CAPACITY CHOICES

Economic implications significantly affect the choices surrounding the capacity of hydraulic energy storage tanks. Cost considerations cover initial investments, maintenance expenses, and operational efficiencies. Investing in larger capacity tanks typically incurs higher initial costs due to materials, labor, and potential site preparations. However, the long-term benefits must also be evaluated concerning potential energy savings and operational efficiencies.

Additionally, the choice of technology greatly influences costs. Advanced materials and innovative design strategies can drive up upfront expenses but reduce lifetime operating costs by providing longer service life and improved efficiencies. The financial viability of any hydraulic energy storage project requires a balanced approach, weighing initial costs against potential long-term operational advantages.

Ultimately, policymakers and businesses must assess the economic landscape and project future energy demands accurately. Fully understanding local energy prices, incentives for renewables, and technological advancements can impact the decision-making process for sizing hydraulic energy storage tanks. Consequently, proper planning and economic analyses are fundamental in maximizing both cost-effectiveness and energy performance.

6. FUTURE TRENDS IN HYDRAULIC ENERGY STORAGE

As technology continues to evolve, future trends in hydraulic energy storage are poised to reshape the landscape. The adaptation of smart technologies, improved materials, and innovative designs is set to enhance capacity and energy efficiency further. One exciting development includes the integration of IoT (Internet of Things) technologies which can provide real-time data and analytics on system performance. By employing sensors within tanks, operators can monitor performance indicators like temperature, pressure, and fluid levels, translating to increased operational agility.

Another promising trend is the exploration of alternative working fluids beyond water. Advances in chemical engineering provide opportunities for utilizing fluids with superior energy storage characteristics. The choice of working fluid affects not only energy capacity but also efficiency and environmental impact. Researchers are focusing on eco-friendly materials that minimize the carbon footprint while enhancing the overall performance of hydraulic storage systems.

Moreover, investments in research and development are likely to yield breakthroughs in tank design and construction methods, potentially decreasing costs and extending operational life. As renewable energy sources gain traction, the role of hydraulic energy storage tanks will likely expand, playing an essential part in achieving energy sustainability and realizing ambitious climate goals.

7. ENVIRONMENTAL IMPACT OF HYDRAULIC ENERGY STORAGE

Environmental considerations are paramount in evaluating the overall impact of hydraulic energy storage systems. While these systems are primarily designed to improve efficiency and reliability in energy systems, their construction and operation can have ecological implications. The location and construction processes must be meticulously planned to prevent disruption to local ecosystems and aquatic environments.

Utilizing environmentally kind materials for tank construction minimizes the carbon footprint associated with their lifespan. Additionally, the energy economy stemming from hydraulic energy systems can lead to decreased greenhouse gas emissions. As reliance on fossil fuels diminishes, the positive ripple effects on air quality and overall ecosystem health can be considerable.

Furthermore, implementing best practices in water management will counterbalance any adverse impacts on local water sources during operation. Striking a balance between energy storage requirements and environmental protection must be at the forefront of hydraulic storage tank development. Ongoing research and advocacy are essential for ensuring the longevity of our planet while facilitating our transition to sustainable energy practices.

8. IMPLEMENTATION STRATEGIES FOR OPTIMIZING CAPACITY

Efficient implementation strategies are vital for maximizing the capacity of hydraulic energy storage tanks. Whether it entails using advanced forecasting techniques or integrating energy management systems, optimizing operational practices contributes to performance improvements. For instance, utilizing predictive analytics can help determine peak demand periods and enhance the tank’s discharge capabilities accordingly.

Moreover, strategic alliances with technology providers may lead to better optimization tools and integration of innovative methodologies. Engineers and project managers should leverage data-driven strategies to assess performance metrics continuously, allowing for timely adjustments based on real-world conditions. Feedback mechanisms can guide decision-making processes, yielding significant enhancements in operational effectiveness and capacity utilization.

A proactive approach is also necessary for maintenance routines, ensuring that the hydraulic systems function at peak efficiency. Utilizing sensors and monitoring technologies can alert operators to maintenance needs before they escalate into larger issues. By committing to regular evaluations and updates, companies can sustain optimal performance, ensuring that the capacity of hydraulic energy storage tanks is always aligned with evolving demands while minimizing operational risks.

FAQs

WHAT FACTORS INFLUENCE THE CAPACITY OF A HYDRAULIC ENERGY STORAGE TANK?

Several critical factors influence the capacity of a hydraulic energy storage tank. The tank’s physical dimensions, liquid density, and operational pressure levels play vital roles. A larger physical size typically allows for more fluid storage, directly impacting the energy capacity of the system. The density of the fluid used, traditionally water, also influences how much energy can be stored. Additionally, the operational pressure is crucial because higher pressures enable more energy storage but also require more robust materials to withstand these conditions. Factors like design integrity, safety mechanisms, and maintenance protocols further add to the complexities of capacity influence. As such, a multi-faceted approach is essential for determining the optimal capacity level across various applications.

HOW DO ENGINEERS DETERMINE THE ENERGY OUTPUT REQUIRED FROM A HYDRAULIC STORAGE SYSTEM?

Engineers ascertain the energy output required from hydraulic storage systems by conducting a thorough analysis of energy demand patterns, peak usage times, and application-specific requirements. Utilizing historical data, forecasts, and simulations can unveil insights into when energy demand peaks occur. Engineers also implement models to assess the expected load during various operating scenarios, helping inform the necessary capacity calculations. Furthermore, using algorithms that incorporate seasonal variations can ensure that energy output corresponds effectively with consumer usage trends. The combination of these methodologies enables a tailored approach that aligns the energy storage system’s capacity and performance with actual operational necessities, leading to greater efficiency and effectiveness.

WHAT IS THE ROLE OF ENVIRONMENTAL CONSIDERATIONS IN THE DESIGN OF HYDRAULIC ENERGY STORAGE TANKS?

Environmental considerations significantly impact the design and implementation of hydraulic energy storage tanks. Minimizing ecological disruption is paramount during construction and operation phases. Engineers must evaluate the optimal locations for tank installation while taking into account local ecology and hydrology. The selection of materials is another crucial aspect; environmentally friendly materials help minimize the carbon footprint of these systems. Furthermore, adherence to regulations regarding water usage can mitigate potential environmental adverse effects. By incorporating these considerations into the design process, developers can enhance the sustainability of energy storage practices while promoting ecological conservation efforts, ultimately paving the way for a greener energy future.

THE CAPACITY OF HYDRAULIC ENERGY STORAGE TANKS PLAYS AN INVOLVED ROLE IN MODERN ENERGY MANAGEMENT. By understanding and implementing nuanced design, operational, environmental, and economic strategies, these systems can serve as crucial enablers of energy sustainability. Ongoing improvements and innovations in technology will further facilitate the development of highly efficient and environmentally-friendly energy solutions tailored to tomorrow’s needs. Ensuring that hydraulic energy storage tanks are designed and operated with these various factors in mind will undoubtedly lead to a robust energy future, balancing the challenges posed by rapid energy transitions across diverse markets.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-is-the-capacity-of-the-hydraulic-energy-storage-tank/