1. The optimal wire for solar photovoltaic panels is Copper, due to its excellent conductivity and durability. 2. The gauge of wire is crucial, with 10-gauge or 12-gauge commonly used to balance performance and resistance. 3. Insulation type matters, particularly with THHN/THWN, suitable for both indoor and outdoor applications. 4. The wire length and routing should be minimized to reduce voltage drop, enhancing overall efficiency.

When considering the installation of solar photovoltaic (PV) panels, the selection of wire plays a vital role in ensuring an efficient and reliable system. Various types of wire are available, each possessing unique properties that can significantly impact performance, reliability, and safety. Thus, understanding these options and their implications is essential for effective solar energy harnessing.

1. CONDUCTIVITY AND MATERIAL SELECTION

When assessing suitability, copper outshines all others, primarily due to its superior electrical conductivity. This characteristic facilitates efficient energy transfer from the solar panels to the inverter and ultimately to the grid or battery storage systems. Furthermore, copper presents greater resilience to environmental factors like temperature changes and moisture, enhancing long-term service life and reduces replacement costs.

In contrast, aluminum may seem a viable substitute due to its lightweight and lower cost. However, its conductivity is inferior to copper, leading to increased resistance and potential energy losses. Additionally, corrosion issues often arise when aluminum is exposed to moisture, making it less ideal for outdoor applications where longevity is a concern. The dilemmas presented by aluminum illustrate why copper remains the predominant choice in the solar sector for high-quality installations.

2. GAUGE OF WIRE AND ITS SIGNIFICANCE

Determining the wire gauge is another critical aspect. Wire gauge is significant because lower gauge numbers mean thicker wire. Thicker wires can carry larger currents with less resistance, minimizing energy loss during transmission. A common practice in solar installations is using 10-gauge to 12-gauge wire based on the current rating of the system.

Selecting the appropriate gauge must also consider the total distance between the solar panels, inverter, and power source. Longer distances may necessitate a thicker wire to offset resistance induced by the wire’s length. Failure to select the right gauge can lead to voltage drop issues, hindering optimal energy production. Employing appropriate gauge requirements, therefore, leads to enhanced efficiency and reliable energy supply.

3. INSULATION TYPES AND THEIR IMPACT

Understanding wire insulation is paramount. The insulation encasing the wire serves multiple functions, including protection from environmental conditions and electrical insulation from inadvertent short circuits. THHN/THWN (Thermoplastic High Heat Resistant Nylon-coated/ Thermoplastic Heat and Water-resistant Nylon-coated) wires are a preferred choice for solar power systems due to their resilience against moisture and high temperatures.

When used in outdoor settings, the insulation must withstand UV radiation and extreme weather conditions. The priority is ensuring that the insulation maintains its integrity over time, mitigating risks of shorts or failures in the system. Wires with inferior insulation properties can deteriorate quickly, leading to increased maintenance costs and potential safety hazards. Thus, selecting wires with appropriate insulation type is critical for ensuring long-lasting performance in solar systems.

4. ROUTING AND LENGTH CONSIDERATIONS

Optimization of wire length and routing contributes significantly to the system’s overall efficiency. Minimizing the distance of wire runs reduces voltage drop, which enhances energy conversion efficiency. It is important to keep wire runs as short as practically possible, maintaining a clear path that avoids unnecessary bends or obstacles.

Excessive lengths can lead to considerable energy loss and reduce the performance of the PV system. Furthermore, careful planning of wire routing minimizes exposure to physical damage, which is crucial in outdoor installations. The layout should be engineered to reduce potential hazards, enabling consistent energy production that solar panels promise to deliver.

5. VOLTAGE DROP AND SYSTEM EFFICIENCY

A critical aspect often overlooked is voltage drop and its implications. Voltage drop refers to the reduction in voltage as electrical current travels through the wire due to resistance. High voltage drops can lead to suboptimal performance of the solar installation, with potential efficiency losses exceeding 10%.

Calculating voltage drop is vital in planning the installation. The National Electrical Code (NEC) recommends that the voltage drop not exceed 3% for circuits feeding a load. Thus, maintaining the wire length within optimal parameters contributes to more efficient operations. Employing larger gauge wires can also counteract the voltage drop, rendering maximum energy utilization from the solar panels.

6. SAFETY REGULATIONS AND CODES

Adhering to safety regulations is paramount for any electrical installation, including solar PV systems. Compliance with local building codes and the National Electrical Code (NEC) ensures installation safety and reliability. Regulations often dictate acceptable wire types, insulation materials, and routing methods to mitigate electrical hazards.

Choosing wires certified for safety enhances the overall performance and reduces risks associated with wiring failures. Failing to comply can lead to dangerous situations such as electrical fires, equipment damage, or even voiding warranties provided by manufacturers. An adequate understanding of local codes ensures that installations meet required standards for performance and safety.

7. COST CONSIDERATIONS

Investing in solar energy is often viewed through the lens of initial costs versus long-term benefits. Wire selection can significantly impact both short-term investments and long-term maintenance. Copper wiring, while initially more expensive than aluminum, often results in lesser replacement costs and improved performance over time.

While the cheaper options may appear more alluring at first glance, hidden costs related to replacement, potential energy losses, and increased maintenance can add up. Additionally, the increased longevity and reliability of better-quality wiring contribute significantly to the overall efficiency and functionality of the solar system, making the initial investment not only wise but necessary for long-lasting performance.

8. ENVIRONMENTAL IMPACT AND SUSTAINABILITY

The environmental implications of wire manufacturing and disposal require contemplation as well. Choosing sustainable wiring options helps minimize the carbon footprint associated with solar installations. Products made from recycled materials or those that offer energy-efficient properties contribute to a greener approach towards energy harvesting solutions.

The lifecycle of the wiring, from production through disposal, should also align with sustainability goals. By selecting high-quality materials that offer durability and longevity, the overall environmental impact diminishes over time, creating a more sustainable solution. This perspective aligns well with the broader objectives of solar energy, promoting eco-friendly practices throughout the energy generation process.

9. INNOVATIONS IN WIRING TECHNOLOGY

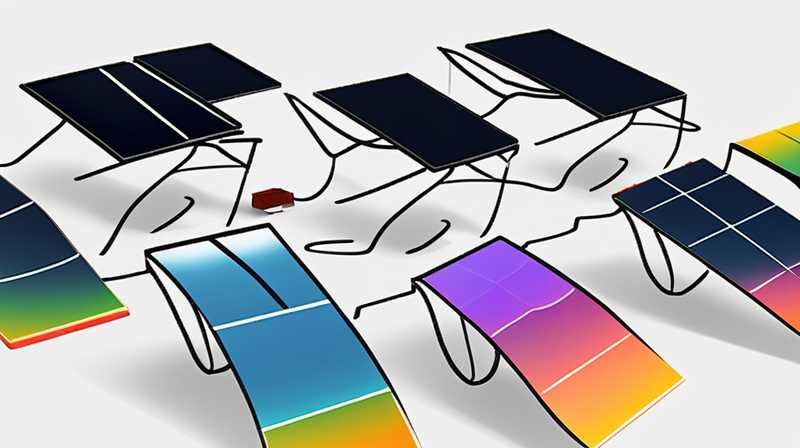

Advancements in technology continuously reshape the solar energy landscape. Innovations in wiring technology focus on enhancing conductivity and developing insulation materials that can withstand extreme environments. Smart wiring options, designed to monitor performance in real time, provide insights that help optimize energy efficiency.

Furthermore, research and development into nano-coatings and alternative materials offer promising enhancements to traditional wiring methods, potentially improving overall performance and extending the lifetime of installations. Tracking these technological advancements can provide insights into the future of solar installations, assisting consumers in making informed choices that reflect modern practices and developments.

FREQUENTLY ASKED QUESTIONS

WHAT WIRE GAUGE IS RECOMMENDED FOR SOLAR INSTALLATIONS?

For solar photovoltaic systems, 10-gauge or 12-gauge wire is typically recommended. The wire gauge selection is based on the current rating of the system and the distance the energy travels from the solar panels to the inverter and beyond. Thicker wires are generally preferred as they facilitate a higher load capacity and reduce resistance, which minimizes energy losses. However, it’s crucial to tailor the wire gauge to the specific requirements of each installation. Consideration must also be given to the overall wire length, as longer distances may necessitate the use of a thicker wire to mitigate voltage drop issues. The specific electrical codes and guidelines provided by the National Electrical Code (NEC) should always be adhered to for both safety and performance.

WHY DOES WIRE INSULATION MATTER WHEN INSTALLING SOLAR PANELS?

Wire insulation plays a crucial role in protecting wires from external conditions and ensuring safety in an electrical installation. Quality insulation materials, like THHN or THWN, are designed to withstand moisture and high temperatures, reducing the risk of short circuits and electrical failures. When installing solar panels, exposure to elements like UV radiation and extreme weather is a significant consideration. Insulation also contributes to the wire’s longevity, ensuring that the electrical system operates reliably over the years without the need for frequent replacements. Poorly insulated wires can lead to electrical hazards and compromises in efficiency, making the choice of suitable insulation essential for safe and effective solar panel installations.

HOW DOES VOLTAGE DROP AFFECT SOLAR ENERGY SYSTEMS?

Voltage drop reflects the decrease in electrical power as it travels through the wiring from solar panels to inverters or storage systems. High voltage drops can significantly impair system efficiency, leading to less energy being converted or stored, diminishing the overall performance of the system. The National Electrical Code (NEC) recommends that voltage drop not exceed 3% for circuits feeding a change in load. Utilizing an appropriately gauged wire and ensuring optimal routing can help mitigate voltage drop, ensuring that the energy harvested from solar panels is utilized efficiently. Monitoring and managing voltage drop are critical for maximizing the total energy output of solar installations; hence proper planning and engineering decisions must be made at the outset.

IN SUMMARY, proper selection of wiring is foundational for the efficiency and effectiveness of solar photovoltaic systems. Each aspect, from material composition to insulation and routing, plays a vital role in overall performance. Understanding and analyzing these dimensions help optimize energy generation and ensure a safe and compliant installation.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-is-the-best-wire-for-solar-photovoltaic-panels-2/