1. The ideal air pressure for energy storage tanks is between 100-150 psi, depending on specific applications. This range ensures optimal efficiency, allowing for effective storage and retrieval of energy. Maintaining appropriate pressure levels is crucial as it affects both the longevity of the equipment and the overall efficiency of energy distribution. It is important to consider factors such as the type of tank, the intended application, and regulatory standards.

UNDERSTANDING AIR PRESSURE IN ENERGY STORAGE TANKS

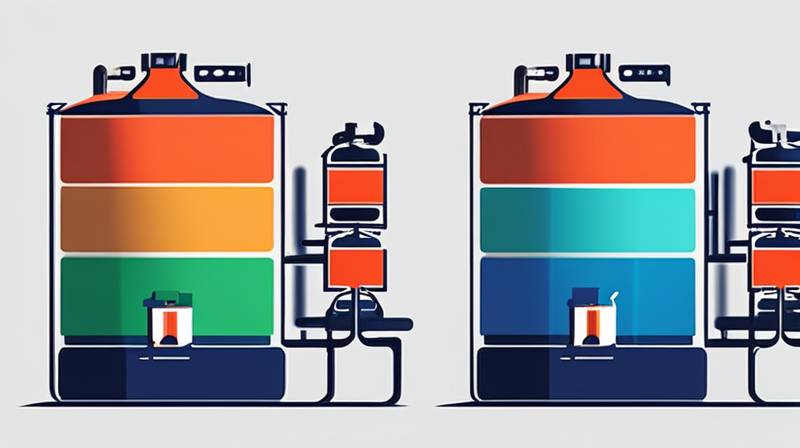

Air pressure within energy storage tanks serves as a vital component of operational efficiency and safety. By grasping how pressure affects tank performance, one can optimize storage systems tailored to diverse needs. High-pressure systems, frequently used in various industrial applications, facilitate the efficient management of compressed air for energy storage. A comprehensive understanding of this concept provides insights into factors affecting performance, maintenance strategies, and safety considerations.

1. THE ROLE OF AIR PRESSURE

Air pressure acts as the driving force in energy storage tanks, determining how efficiently energy can be stored and released. Within these systems, compressed air functions as an energy medium, translating potential energy into usable forms when released. Inadequate pressure can lead to energy losses during the conversion and distribution processes.

Moreover, while high pressure can enhance storage capacity, it also necessitates careful management to prevent system failures. Monitoring pressure levels is essential, as deviations can lead to adverse consequences impacting both operational efficiency and safety protocols. Tanks must be designed to withstand elevated pressures, with robust materials ensuring structural integrity.

2. FACTORS AFFECTING OPTIMAL AIR PRESSURE

Several factors determine the ideal air pressure for energy storage tanks. These factors include tank design, intended application, ambient conditions, and user requirements. Each variable plays a critical role in establishing parameters for maximum efficiency.

Tank design is one of the most significant influences on pressure requirements. For instance, cylindrical tanks can handle higher pressures due to their geometric shape, evenly distributing loads. Conversely, a rectangular tank might require pressure adjustments to maintain stability and safety. Proper engineering ensures these tanks can operate reliably within specified pressure ranges.

Then, intended applications—for example, in energy transmission versus industrial uses—require distinct pressure settings. Energy transmission may retain lower pressure pathways, allowing for energy to efficiently travel over long distances. In contrast, applications requiring immediate energy retrieval may necessitate higher pressures, emphasizing the need for careful planning in system design.

3. REGULATORY STANDARDS AND SAFETY

Compliance with regulatory standards is paramount in determining the acceptable pressure ranges for energy storage tanks. Regulatory bodies impose guidelines around pressure handling to protect operators and the surrounding environment from potential hazards. All stakeholders must stay informed about these regulations to avoid costly penalties and promote safe operational practices.

Incorporating robust safety mechanisms into storage tanks also plays a crucial role. While maintaining an ideal pressure range is essential for efficiency, system redundancies that activate during emergencies—such as pressure relief valves—are critical. These systems ensure that even under stress, safety is not compromised. Frequent pressure monitoring is crucial to verify compliance with established safety norms, forming an integral part of operational protocol.

4. PERFORMANCE MONITORING AND MAINTENANCE

Regular maintenance and performance monitoring can greatly reduce operational risks associated with energy storage tanks. Implementing a routine check-up schedule allows for the proactive identification of potential issues, including pressure irregularities. By tracking these metrics closely, operators can effectively manage tank performance.

Monitoring technologies, such as pressure gauges and data loggers, enable continuous assessment of tank conditions. These advanced systems not only fulfill operational needs but also provide actionable insights into potential improvements. By analyzing historical data, one can identify trends that inform the decision-making process regarding maintenance and upgrades.

5. APPLICATIONS OF ENERGY STORAGE TANKS

Energy storage tanks have diverse applications across multiple sectors. Understanding these practical uses highlights the importance of maintaining appropriate air pressure for specific tasks. Examples include renewable energy storage, industrial applications, and even residential models designed for sustainability.

In renewable energy settings, such as wind or solar installations, compressed air systems allow energy to be stored during peak production times and released during periods of low generation. This capability directly ties into air pressure management, as achieving optimal pressure levels ensures energy availability when demand arises. Wind energy sites utilize high-pressure systems to store excess energy, balancing supply and demand effectively.

6. EVOLUTION OF AIR STORAGE TECHNOLOGIES

Recent advancements in energy storage technologies have transformed the landscape of compressed air storage. Emerging technologies, such as integrated storage solutions, utilize smart monitoring systems to maximize efficiency. Awareness of these innovative approaches can drive better investment decisions and long-term planning.

As technology continues to evolve, organizations must keep abreast of the latest developments to enhance their operations. By exploring the prospects of modern air storage solutions, operators can augment their energy management strategies and improve overall system performance.

COMMONLY ASKED QUESTIONS

WHAT IS THE FUNCTION OF AIR PRESSURE IN ENERGY STORAGE TANKS?

Air pressure primarily functions as the driving force within energy storage tanks, enabling the effective management of compressed air as an energy medium. By generating pressure, these tanks can store potential energy efficiently for later use. Adequate pressure levels facilitate seamless energy release during demand periods while maintaining structural integrity and safety. Thus, understanding the interplay between pressure and energy storage capacity becomes pivotal for operators seeking to optimize performance.

HOW DOES HIGH PRESSURE AFFECT TANK SAFETY?

High-pressure levels can lead to increased risks if not managed properly. Excessive pressure may exceed the tank’s structural limits, causing failures that jeopardize safety and maintenance protocols. Therefore, compliance with established safety standards, alongside the implementation of monitoring systems, becomes essential in maintaining safe operational pressures. Continuous pressure assessment and the integration of safety devices—such as pressure relief valves—are necessary to mitigate risks associated with high-pressure systems. Ultimately, balancing optimal performance with safety is crucial for long-term operational resilience.

WHAT MAINTENANCE IS REQUIRED FOR AIR STORAGE TANKS?

Regular maintenance of air storage tanks includes routine inspections, pressure monitoring, and system cleanings. Scheduled check-ups provide insights into the tank’s condition and help identify any potential hazards before they escalate. Monitoring technologies should be implemented to collect data consistently, enabling operators to make informed decisions regarding maintenance and repairs. Proper upkeep, alongside compliance with regulatory standards, ensures operational efficiency and significantly reduces the risk of failures due to unaddressed issues.

In summary, the optimal air pressure for energy storage tanks is critical for achieving efficiency, safety, and longevity. Appropriately maintained air pressure ranges—generally between 100-150 psi—promote effective energy management in various applications. Monitoring systems, robust designs, and adherence to safety protocols work in concert to mitigate risks. This multifaceted approach creates a balanced system in which both performance and safety can thrive. Continuous advancements in technologies and a deeper understanding of air pressure functions are essential for maximizing the efficiency of energy storage solutions. As industries evolve, the importance of air pressure management in energy storage will only increase, necessitating ongoing research and innovative practices that push boundaries for future applications. Through focused efforts on optimal operating conditions and responsible design, stakeholders can ensure sustainable practices while meeting growing energy demands.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-is-the-best-air-pressure-for-energy-storage-tanks/