The back of a physical solar panel refers primarily to the rear-facing components and materials that contribute to the overall efficiency and durability of the unit. 1. The back provides thermal insulation, 2. It includes protective layers against environmental elements, 3. It houses wiring and electrical connections, 4. It impacts the panel’s longevity and performance. For instance, the back layer usually consists of a durable material, such as ethylene-vinyl acetate (EVA) or Tedlar, which serves as a protective barrier against moisture, UV radiation, and extreme weather conditions. The effectiveness of this back layer is crucial for maintaining the efficiency of energy conversion and prolonging the panel’s operational lifespan since any degradation in materials could potentially lead to decreased performance over time.

1. STRUCTURAL COMPONENTS OF THE BACK OF A SOLAR PANEL

The rear side of solar panels is equipped with various structural components designed to enhance durability and optimize functionality. These elements work together to protect the sensitive internal components from external environmental factors like moisture, temperature fluctuations, and physical damage. This section will delve into the significance of materials used for the rear structure, covering both durability and thermal efficiency.

The back of a solar panel often employs materials engineered to withstand harsh conditions. Polymeric materials, such as Tedlar, are prevalent because of their remarkable resistance to UV radiation and moisture. This protective layer functions not only as a shield against environmental hazards but also prevents degradation of the internal components, which can lead to energy loss and a shortened lifespan of the solar unit. The choice of material for the rear-facing side is critical, as it directly correlates with the energy efficiency of the panel. Thus, high-quality backing materials are vital for maintaining optimal operational efficiency over extended periods.

Moreover, manufacturers often implement intricate designs in the rear structure to facilitate thermal management. The effectiveness of thermal insulation directly impacts the performance of the solar panel. As temperature increases, solar cells can become less efficient, so optimizing the back layer to reduce heat retention is essential. By using materials with high insulation properties, manufacturers can mitigate heat buildup, ensuring the solar panel operates effectively even in high-temperature scenarios. Controlling the operating temperature of solar cells enhances overall output, making it a priority for designers and engineers.

2. ELECTRICAL CONNECTIONS AND WIRING SCHEMES

Understanding the electrical connections that reside at the back of solar panels is vital in grasping how these systems function efficiently. Correct wiring and integration of electrical components are key to maximizing energy conversion and ensuring the effective operation of the entire unit. This section examines how these electrical components work together and how their placement affects performance, safety, and maintenance.

Typically, the back of a solar panel features junction boxes that serve as hubs for wiring and protective circuits. The junction box houses critical electrical components, including diodes that prevent current flow back into the solar cells at night. This configuration not only aids in optimizing the energy capture during the day but also enhances the overall safety of the solar system. Diodes minimize the risk of overheating and potential fires, making their presence on the back side of solar panels crucial for operational safety.

Furthermore, the arrangement of wiring has implications for both performance and maintenance. The connections must be organized efficiently to prevent any potential issues such as fraying or overtension that could lead to electrical failure. Properly routed wires help to maintain the aesthetic appeal of the installation and simplify troubleshooting should any problems arise. The back of the solar panel is thus not just a protective layer; it’s a crucial interface where electrical integrity meets physical durability, contributing to the successful operation of solar technology overall.

3. IMPACT OF BACK MATERIALS ON PERFORMANCE

The materials utilized for the back layer of solar panels significantly impact their performance and longevity. This aspect goes hand-in-hand with the efficiency of energy conversion, which is paramount for maximizing the benefits of solar technology. In this portion, we will assess how various materials influence performance metrics, along with their contributions to energy efficiency.

One of the most critical aspects to consider is the reflectivity of back materials. Materials that possessing higher reflectivity can bounce heat away from solar cells, thus ensuring they operate at optimal temperatures. This feature is essential because excessive heat can lead to reduced efficiency, causing a decline in energy output. Certain innovative manufacturers are adopting technologies like selective coatings that not only provide protection but also reflect and dissipate heat effectively, enhancing thermal management strategies incorporated within their panels.

Additionally, the choice of back material influences the panel’s susceptibility to wear and tear. Longevity is primarily dependent on both environmental exposure and the degradation resistance of back materials. For example, panels with cheap backing materials may be prone to physical damage or environmental stressors, resulting in malfunction or reduced efficiency over time. Thus, the strategic selection of back materials is vital for ensuring that solar panels achieve extended operational lifetimes while minimizing maintenance costs and downtime.

4. ADVANCEMENTS IN BACK MATERIAL TECHNOLOGY

Technology is consistently evolving, and advancements in the materials used for the back of solar panels can lead to significant improvements in functionality. Keeping pace with innovations allows manufacturers to provide more effective, reliable, and versatile products to the market. This segment will explore some of the latest trends in back material technology as well as their potential implications for the industry.

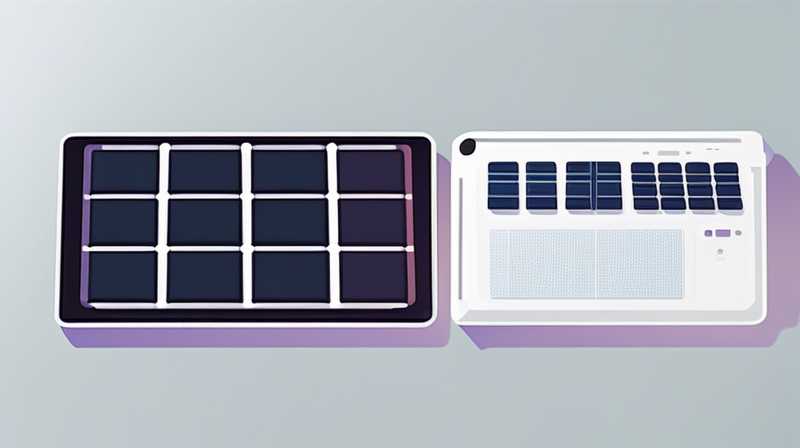

Recent advancements include the development of bifacial solar panels, which feature transparent backs that allow light to penetrate from beneath. This design enables the use of reflected light from the ground or surrounding surfaces, effectively increasing overall energy capture. These innovative structures signify a shift in traditional solar technology and demonstrate the potential for higher efficiency levels compared to their monofacial counterparts. As the solar market trends toward diversified approaches for increasing efficiency, these technologies’ advent emphasizes the need for future-focused back materials.

Additionally, ongoing research into high-tech polymers and composites is changing the landscape of solar panel manufacturing. Enhanced durability against environmental factors, combined with improved thermal properties, allows manufacturers to produce panels that perform efficiently in a broader range of conditions. The incorporation of nanomaterials and coatings can lead to surfaces that resist dirt accumulation, further ensuring efficient energy conversion by allowing maximum sunlight exposure. The implications of these developments are colossal, not only in terms of performance but also regarding environmental sustainability, since more advanced materials can lead to lower production costs and less waste.

FAQS

WHAT ARE THE COMMON MATERIALS USED FOR THE BACK OF SOLAR PANELS?

Common materials for the rear of solar panels include Tedlar, EVA, and glass. Tedlar is a polyvinyl fluoride (PVF) film known for its excellent resistance to UV radiation and moisture, making it an ideal protective layer. Ethylene-vinyl acetate (EVA) is often used as a binding layer that secures solar cells in place while providing some thermal insulation. Glass is sometimes incorporated in bifacial panel designs, as it allows for light to enter from both sides of the panel, which can enhance energy production. Each material has specific properties that help protect the panel’s integrity and improve its overall performance, helping to ensure the longevity of the solar system as a whole.

HOW DOES BACK MATERIAL AFFECT SOLAR PANEL EFFICIENCY?

The efficiency of solar panels is significantly influenced by the back materials employed. Materials with high reflectivity can reduce heat absorption, helping to maintain optimal operating temperatures for solar cells. Excessive heat can lead to a reduction in efficiency—a phenomenon known as thermal derating. Additionally, the quality of the back layer determines its resilience against environmental damage, which can impact the panel’s lifespan and energy output. Hence, high-quality back materials contribute to a more stable performance across changing environmental conditions, effectively maximizing energy production rates.

CAN SOLAR PANEL BACKS BE REPLACED OR REPAIRED?

In many cases, replacing or repairing the back of a solar panel is not a practical solution. Solar panels are designed as sealed units, meaning that access to internal components is often limited. If the back layer becomes damaged or deteriorates, it generally affects the entire system’s integrity, leading to diminished energy production. Instead of repair, replacement of the entire panel is recommended to ensure safety and optimal performance. Regular maintenance and inspections can help catch any minor issues early on, potentially preventing extensive damage and extending the lifespan of the solar power system.

The importance of the back components of solar panels cannot be overstated. The rear structure not only serves protective purposes but also significantly contributes to thermal management and energy efficiency. Selecting appropriate materials like Tedlar or EVA allows for optimal durability while minimizing thermal derating, thereby enhancing overall performance. Moreover, the incorporation of advanced technologies such as bifacial designs represents a paradigm shift in solar efficiency, driving the market towards innovation in material selection and production methods. Ultimately, the choices made regarding the back layer of solar panels have profound implications for the longevity of these systems and their ability to provide sustainable energy solutions. As the solar energy sector continually evolves, keeping abreast of advancements in back materials will allow stakeholders to make informed choices that benefit both the environment and the economy. By investing in high-quality back structures and staying attuned to emerging technologies, manufacturers can help ensure their products remain competitive in the ever-growing solar market, thus contributing to the broader goal of sustainable energy consumption.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-is-the-back-of-a-physical-solar-panel/