The appropriate pressure of an energy storage tank depends on various factors including the type of system, application requirements, and safety considerations. 1. The pressure should be tailored to the specific energy storage mechanism being employed, such as compressed air, hydrogen, or liquid storage. 2. Optimal pressure settings typically enhance the efficiency of energy retrieval, ensuring that stored energy can be accessed effectively. 3. A careful assessment of materials and structural capabilities of the tank is essential, as each material exhibits unique pressure tolerances that impact durability and safety. Among these points, a nuanced focus on the application requirements, for instance, the intended energy output and environmental conditions, deserves particular attention. This aligns the pressure settings with operational needs, ultimately leading to better performance and resource management.

1. UNDERSTANDING ENERGY STORAGE TANKS

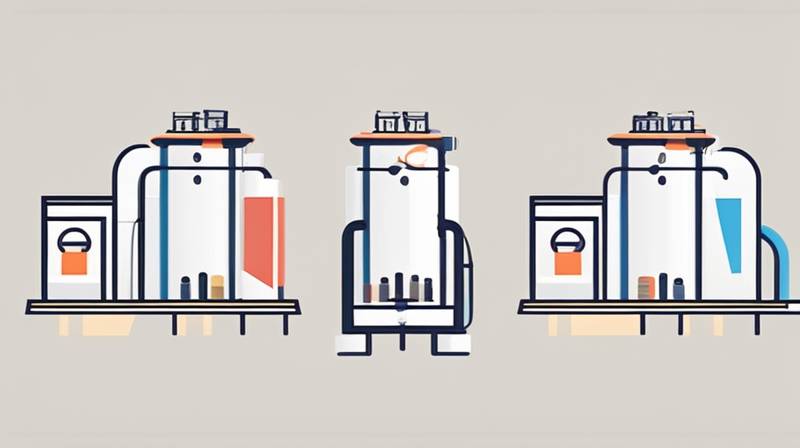

Energy storage tanks serve a pivotal role in modern energy management systems, facilitating the capture, retention, and release of energy. Tanks can be categorized into various types, including mechanical, thermal, and chemical storage systems. Each type operates under distinct principles that dictate their design and operational characteristics. For instance, compressed air energy storage (CAES) relies on high-pressure systems to store energy in the form of compressed air, while thermal storage systems utilize materials that store heat.

The operational efficiency of these systems significantly hinges on the pressure levels within them. In CAES systems, pressure levels directly influence how much energy can be stored and how quickly it can be released. Higher pressures typically enable greater energy density, allowing for more efficient storage solutions. Understanding the implications of energy storage pressures lends insight into the overall performance and reliability of these systems, which is crucial for industries aiming for sustainable solutions.

2. FACTORS INFLUENCING PRESSURE SETTINGS

Multiple variables influence the determination of appropriate pressure levels in energy storage tanks. First, the specific application necessitates scrutiny. Different applications demand varying pressure ranges; for instance, pressure requirements for industrial-scale energy management may differ dramatically from those needed for residential applications. A detailed analysis of the operational context informs pressure adjustments tailored to maximize system performance.

Another essential factor is the structural integrity of the tank material. Pressure capacities rely heavily on the physical characteristics of the tank’s construction material. Materials such as carbon steel, stainless steel, or composite materials each exhibit different tolerances to stress and pressure variations. Choosing the right material is vital, not just for performance, but also for safety, as exceeding a material’s limits may lead to catastrophic failure. As such, assessing material properties, together with intended use cases, forms the basis for establishing safe pressure thresholds.

3. SAFETY CONSIDERATIONS IN PRESSURE MANAGEMENT

Safety considerations are paramount when it comes to managing pressure levels within energy storage tanks. Over-pressurization poses severe risks, including rupture or explosion, resulting in significant financial loss and harm to personnel. Recognizing these hazards emphasizes the need for strict adherence to safety guidelines and regulations governing maximum pressure thresholds for different storage systems.

Implementing robust pressure monitoring systems serves as an essential strategy in this context. Continuous monitoring allows for real-time adjustments based on fluctuations in temperature and external environmental conditions. Technologies such as pressure transducers can provide instantaneous feedback, giving operators the ability to respond proactively to potential fluctuations that may jeopardize tank integrity. Furthermore, regular inspections and maintenance routines are advised to ensure tanks remain within safe operational boundaries.

4. OPTIMIZING PRESSURE FOR EFFICIENCY

Enhancing overall efficiency in energy retrieval is a critical objective for storage systems. Optimal pressure settings enable better control over the energy release process. For example, in thermal storage systems, managing the pressure of gases can optimize heat transfer efficiency, significantly impacting the energy yield.

When assessing performance metrics, it is important to consider how pressure influences energy conversion rates. Higher pressures can facilitate quicker energy release, which is beneficial in applications requiring rapid energy deployment, such as grid balancing. However, this must be balanced against energy losses that may occur if pressures are increased beyond efficient operating parameters. Therefore, conducting rigorous simulations and tests will aid in fine-tuning the pressure settings for top-tier performance and energy management.

5. COMMON USAGE OF ENERGY STORAGE TANKS

The numerous applications of energy storage tanks highlight their versatility and significance in energy management systems. Renewable energy integration stands as one of the most prominent use cases. As solar and wind power generation can be intermittent, energy storage tanks enable the retention of excess energy for use during low production periods.

In industrial applications, energy storage tanks can serve to stabilize operations by providing a buffer during peak demands. This flexibility allows for improved load management, ensuring that enterprises minimize waste and optimize resource utilization. By understanding the unique requirements of each application, stakeholders can more effectively define appropriate pressure ranges tailored to their specific scenarios.

6. REGULATORY FRAMEWORKS AND INDUSTRY STANDARDS

Before establishing pressure limits for energy storage tanks, familiarity with relevant regulatory frameworks is essential. Various safety standards exist to guide the design and operation of storage systems. Organizations like the American Society of Mechanical Engineers (ASME) provide guidelines that ensure both structural integrity and operational safety.

Compliance with these standards not only ensures safety but also fosters worker confidence and public trust. The regulatory landscape is complex; thus, constant engagement with state and federal regulations ensures that operators remain updated with changing laws. Understanding these frameworks further elevates the operational discipline of energy storage systems and enhances reliability.

7. EMERGING TECHNOLOGIES IN ENERGY STORAGE

New technologies are driving innovations in energy storage methodologies, particularly in pressure management. Advancements in materials science are producing lighter and stronger materials that can withstand higher pressures, revolutionizing tank design and functionality. These materials can enhance performance, particularly in applications where weight and space are critical considerations.

Additionally, the integration of artificial intelligence and machine learning in monitoring systems provides unprecedented levels of precision in pressure control. These technologies allow for predictive maintenance and real-time adjustments, thus empowering operators to optimize energy storage tanks for changing conditions dynamically. Such innovations exemplify the importance of integrating modern technology into traditional energy management systems.

8. REAL-WORLD EXAMPLES OF PRESSURE MANAGEMENT

Examining specific case studies reveals best practices in effective pressure management within energy storage tanks. For example, the implementation of CAES systems in Germany demonstrates how rigorously controlled pressure environments can improve energy reliability. The facility effectively manages energy demands through a series of geological formations that serve as natural tanks, illustrating the nuanced approaches to pressure settings.

Similarly, researchers at several universities are conducting experiments to identify optimal pressure levels for hydrogen storage. These studies are critical to advancing safety protocols and improving efficiency in hydrogen production and usage. By analyzing real-world applications, one can glean insights into optimal practices for pressure determination across various energy storage contexts.

FAQs

WHAT IS THE IMPACT OF HIGH PRESSURE ON ENERGY STORAGE EFFICIENCY?

A higher pressure in energy storage systems can significantly enhance efficiency by increasing energy density and enabling faster retrieval rates. However, this comes with trade-offs. Excessive pressure increases material stress, which can lead to safety hazards such as leaks or ruptures. Therefore, it is crucial to balance operational pressures with the structural tolerance of tank materials. In applications such as compressed air energy storage, higher pressures allow for larger energy storage capacities, but careful monitoring is necessary to avoid over-pressurization.

Moreover, pressure losses in the system must also be accounted for to optimize overall energy conversion efficiency. Efficient system design considers not only maximum pressure thresholds but also how these conditions affect energy loss during storage and retrieval processes. Ultimately, a meticulous evaluation of both benefits and risks is required to determine optimal pressure levels for particular applications.

HOW OFTEN SHOULD ENERGY STORAGE TANKS BE INSPECTED FOR PRESSURE CHECKS?

Regular inspections are vital in maintaining the integrity and optimal performance of energy storage tanks. Experts recommend performing inspections at least once a year, although more frequent assessments may be necessary depending on the operational context and pressure levels involved. High-pressure systems, particularly, warrant more rigorous checks to ensure that all components are functioning within safe limits.

During these inspections, trained personnel should evaluate tank materials, fittings, and monitoring equipment for any signs of wear or stress. Utilizing advanced inspection techniques such as ultrasonic testing can help in detecting potential failures before they escalate. In regulated industries, compliance with legal inspection protocols further underscores the necessity of routine evaluations. Ultimately, diligent inspections are a pro-active approach toward sustaining the safety and efficiency of energy storage tanks.

WHAT TYPE OF MATERIAL IS BEST FOR HIGH PRESSURE ENERGY STORAGE TANKS?

Choosing the right material for energy storage tanks is critical, especially in high-pressure applications. Steel alloys, particularly carbon steel and stainless steel, are frequently utilized due to their robust structural properties and ability to accommodate higher pressures without compromising integrity. These materials offer durability, resistance to corrosion, and thermal stability, making them favorable choices for various applications.

Recent developments have introduced composite materials that combine lightweight properties with high strength, allowing for innovative tank designs. These materials can often withstand significant pressure while enhancing transportability and ease of installation. Ultimately, the selection of materials must align with specific operational demands and regulatory guidelines to ensure safe and effective energy storage.

The pressure in energy storage tanks is a complex topic that requires a multifaceted approach to ensure efficiency and safety. Understanding the specific application requirements, taking into account safety protocols, and selecting suitable materials serves as the foundation for establishing optimal pressure levels. The integration of advanced technologies into inspection and monitoring further enables enhanced performance and reliability across various applications. Ultimately, a well-rounded consideration of all these elements contributes significantly to the effective management of energy storage systems.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-is-the-appropriate-pressure-of-the-energy-storage-tank/