The ALD (Atomic Layer Deposition) method for solar cells refers to a sophisticated thin-film deposition technique offering various advantages in the production of solar photovoltaic devices. 1. ALD enhances efficiency in solar cells, 2. It allows for precise control over layer thickness, 3. The process can enable complex material integration, 4. It provides a uniform coating on substrates regardless of shape or size.

The most significant aspect of ALD is its ability to create ultra-thin films with atomic-level precision, which optimizes the absorption and conversion of solar energy, leading to improved solar cell performance. This precision not only maximizes efficiency but also helps in developing new materials suited for next-generation photovoltaic systems.

1. UNDERSTANDING ALD TECHNIQUE

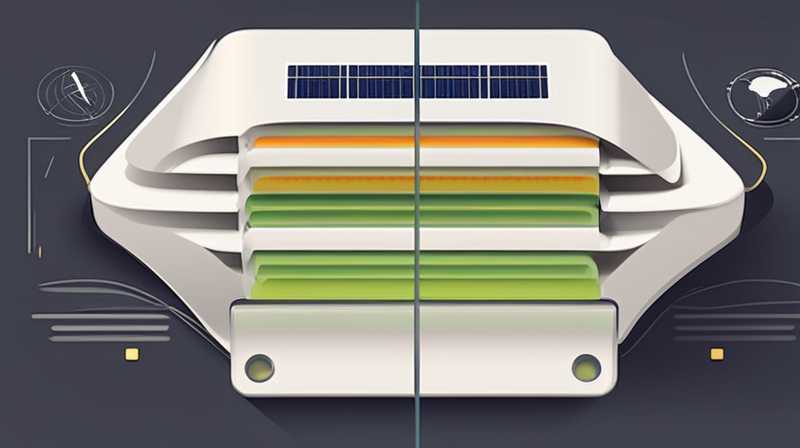

Atomic Layer Deposition represents a remarkable shift in the realm of thin-film deposition methodologies. This technique is characterized by sequential, self-limiting surface reactions, allowing for the deposition of materials one atomic layer at a time. This means that unlike traditional coating methods, where materials may be unevenly applied leading to imperfections, ALD ensures uniformity and precise control over film thickness even at the nanoscale.

ALD operates typically in a vacuum environment, using reactors that can accommodate various substrates. The process involves alternating exposures of gaseous precursors to the substrate material, where one reacts with the surface and saturates it before the second precursor is introduced. This dual-phase reaction mechanism permits high conformity even on complex geometries, ensuring complete coverage. Consequently, the controlled nature of ALD allows for the deposition of a wide variety of materials, which can be finely tuned to achieve specific properties essential for solar applications.

2. ADVANTAGES OF ALD FOR SOLAR CELLS

The ALD methodology showcases several benefits, particularly in the context of solar photovoltaic technology. First and foremost, ALD offers unparalleled control over film thickness, which is critical for optimizing photovoltaic layers. This control enables the precise engineering of materials, allowing researchers and manufacturers to manipulate electronic properties precisely.

Moreover, the self-limiting nature of ALD allows for the deposition of high-quality dielectric and semiconductor materials essential in solar cells without fear of oversaturation or defects that can arise from conventional deposition methods. ALD’s ability to uniformly coat surfaces equips it to adeptly handle intricate geometries, a significant advantage in modern solar cell designs. Traditional deposition techniques may struggle to achieve similar quality on non-planar or textured surfaces. Furthermore, the compatibility of ALD with various materials extends its applicability to a broader spectrum of solar technologies, including organic photovoltaics and advanced ceramics.

3. APPLICATIONS OF ALD IN SOLAR PHOTOVOLTAIC DEVICES

In contemporary solar cell research and development, ALD has found extensive applications across various types of photovoltaic technologies. Thin-film solar cells, especially those using Cadmium Telluride (CdTe) and Copper Indium Gallium Selenide (CIGS), benefit tremendously from ALD deposition. For instance, ALD can be employed to deposit antireflective coatings and buffer layers, enhancing the light-harvesting abilities of these thin films.

Moreover, the application of ALD in multi-junction solar cells presents significant advancements in efficiency. By facilitating the deposition of complex multi-layer structures with different materials tailored for specific spectral ranges, ALD can optimize energy absorption across a wider range of solar irradiation. Ultimately, this multifaceted approach maximizes the energy conversion efficiency of solar devices, pushing the boundaries of what is feasible in solar energy technology.

4. CHALLENGES AND LIMITATIONS OF ALD IN SOLAR TECHNOLOGY

Despite its many advantages, the incorporation of the ALD technique in solar cell manufacturing also encounters several challenges and limitations. One primary concern is the economic aspect. The intricate nature of the ALD process often entails higher initial capital investment due to specialized equipment and extended process times.

Additionally, while ALD is adept at producing extremely thin layers, each cycle typically takes a substantial amount of time. As such, the scalability of ALD for large-scale production remains an important consideration. Manufacturers may need to balance the benefits of ALD’s precision with the throughput required for commercial viability. Nevertheless, researchers are actively investigating strategies to improve reaction speeds and reduce costs while maintaining the high standards of quality associated with ALD.

5. FUTURE OF ALD IN SOLAR CELL TECHNOLOGIES

Looking ahead, the future of Atomic Layer Deposition within the solar sector appears promising as continual advances in nanotechnology and materials science unfold. Emerging novel materials such as perovskites, known for their robust solar cell performance, can potentially be enhanced using ALD techniques to improve stability and efficiency.

Furthermore, integrating ALD with other deposition methods could offer synergies that lead to innovative strategies in solar cell fabrication. The advancements in computational materials science coupled with ALD may usher in the development of entirely new classes of photovoltaic materials, propelling solar energy into the forefront of renewable energy sources. The ongoing research and development endeavors focusing on optimizing ALD processes and exploring its applicability across different solar technologies will play a crucial role in shaping the next generation of energy conversion devices.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE MAIN BENEFITS OF USING ALD FOR SOLAR CELLS?

The advantages of utilizing Atomic Layer Deposition for solar cells are significant and multifaceted. Firstly, ALD is notable for its precision in film thickness control. This capability enables manufacturers to engineer optimally tailored layers essential for photovoltaic applications. The ability to deposit the materials one atomic layer at a time results in uniform coverage with reduced defects.

Moreover, this method facilitates the application of layers on complex substrates, which is an essential feature when dealing with modern solar cell designs. The self-limiting nature of ALD also allows for better material utilization, ensuring that minimal waste occurs during the deposition processes. Additionally, ALD can be used to deposit a variety of materials, allowing for versatility in the integration of different functionalities into solar cells, thus pushing the efficiency and performance of these devices significantly forward.

HOW DOES ALD COMPARE TO OTHER DEPOSITION METHODS?

Atomic Layer Deposition exhibits a distinct set of characteristics that differentiate it from other thin-film deposition techniques such as chemical vapor deposition (CVD) and physical vapor deposition (PVD). The primary difference lies in the self-limiting nature of ALD, a feature that grants it an unparalleled layer-by-layer deposition capability. In contrast to CVD, where the reaction may continue beyond the desired thickness leading to potential defects, ALD guarantees precision by only allowing a designated number of atomic layers to form.

Furthermore, the conformality of ALD is superior when compared to many traditional methods. This quality is particularly beneficial for coating intricate or complex three-dimensional surfaces, which is essential in maximizing the efficiency of solar cells’ light absorption capabilities. While ALD processes can be slower and more costly, the high quality and control offered by this method make it a preferred choice for cutting-edge applications requiring utmost precision.

WHAT ARE THE CURRENT RESEARCH TRENDS FOR ALD IN SOLAR TECHNOLOGY?

Research in the domain of Atomic Layer Deposition for solar technology is currently burgeoning with various promising trends. There is a strong emphasis on enhancing the materials used in solar photovoltaics, including the exploration of advanced compounds such as perovskites. Researchers are examining how ALD can optimize the stability and efficiency of perovskite solar cells through the deposition of protective layers or conductive materials.

In addition, the integration of ALD techniques with innovative approaches, such as in-situ monitoring and machine learning algorithms, is gaining traction. These advancements aim to improve the efficiency and speed of the deposition processes while maintaining control over the deposition characteristics. Continuous exploration of scalable systems that can leverage ALD for economic large-scale production is also a focal point, indicating a thriving research landscape poised to drive significant advancements in solar energy technology.

In summary, the Atomic Layer Deposition technique stands out as a transformative technological advancement in the pursuit of optimizing solar cell performance. This method empowers researchers and manufacturers to achieve stringent precision levels in material deposition, surpassing limitations set by traditional techniques. As the demand for renewable energy sources intensifies globally, the role of ALD in enhancing the efficiency of solar photovoltaics becomes increasingly pivotal. With ongoing research and development exploring new materials and integration techniques, the prospects for ALD in solar technology remain bright and promising.

Future innovations in ALD could lead to breakthrough applications not only in solar energy but also in numerous other fields where precise material control is crucial. The continuous evolution of ALD technologies will undoubtedly contribute to more efficient, sustainable energy solutions, thus fostering advancements that may reshape the solar landscape considerably.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-is-the-ald-method-for-solar-cells/