What is solar circuit board p

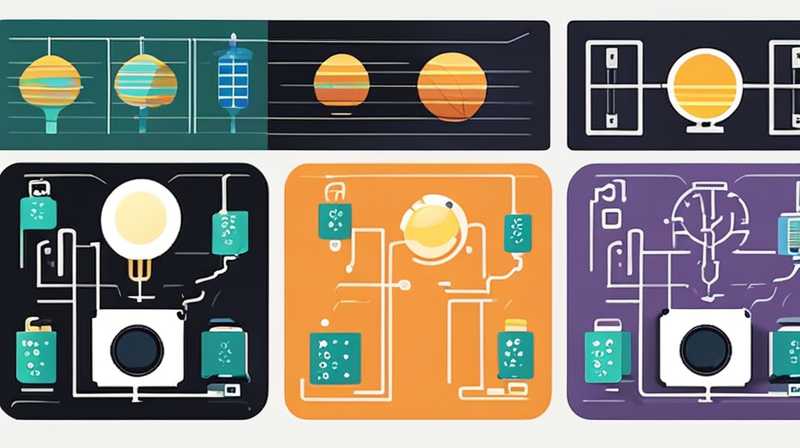

- A solar circuit board p is a specialized printed circuit board (PCB) designed for solar energy applications. 1. The primary function is to manage power distribution, 2. It incorporates advanced materials ensuring efficiency, 3. It handles complex circuitry while promoting sustainable energy, and 4. It is essential for optimizing solar panels’ performance. These boards are crucial in photovoltaic systems, where they enable effective energy conversion by connecting various components. The intricate nature of solar energy systems necessitates highly efficient and durable circuit boards that can withstand environmental stress while maximizing the use of solar energy for various applications.

1. UNDERSTANDING SOLAR CIRCUIT BOARD P

The term “solar circuit board p” signifies a type of printed circuit board crafted specifically for applications in solar energy systems. These PCBs are integral for regulating and distributing power within solar installations, ensuring that the energy converted from sunlight is effectively harnessed and utilized. The design and structure of these boards are meticulously engineered to accommodate the unique demands posed by solar energy technology.

In essence, the solar circuit board p serves as the central nervous system of photovoltaic devices. By facilitating connections among different components, such as solar cells, inverters, and batteries, it plays a pivotal role in enhancing performance and reliability. The transition to renewable energy sources has necessitated advancements in the technology used in circuit boards, emphasizing the importance of efficiency and durability.

2. COMPONENTS OF SOLAR CIRCUIT BOARDS

There are several critical components found within solar circuit boards that allow them to function optimally in solar energy systems. 1. Solar cells, 2. The inverter, 3. Charge controllers, and 4. Interface circuits are among the primary elements that make up these intricate boards.

Solar cells are the primary source of energy in photovoltaic systems, and their integration into circuit boards is essential for the direct conversion of sunlight into electricity. The inverter is another vital component, as it transforms the direct current (DC) generated by solar cells into alternating current (AC), which can then be utilized by household appliances or fed back into the electrical grid. Charge controllers are crucial for maintaining optimal battery performance, preventing overcharging and ensuring longevity. Finally, interface circuits facilitate communication between the various components, allowing for the effective monitoring and management of energy flow.

The interconnection of these components must be done with precision, as even minor flaws in the circuit board can lead to significant efficiency losses. The layout of traces and pads on the board must minimize resistance and maximize conductivity, ensuring that energy transfer occurs seamlessly.

3. MATERIALS USED IN SOLAR CIRCUIT BOARDS

The materials employed in constructing solar circuit boards are vital in determining their performance characteristics and overall reliability. 1. Epoxy resin, 2. Copper layers, 3. Silicone, and 4. Ceramics are commonly used materials that contribute to the functionality and durability of these boards.

Epoxy resin is widely favored due to its excellent insulation properties and resistance to mechanical stress. This material helps protect the circuitry from environmental factors such as moisture and dust, which could otherwise compromise performance. Copper layers serve as the conductive pathways in the circuit, enabling the efficient transfer of electricity throughout the solar system. The thickness and quality of the copper used can significantly impact the system’s efficiency, necessitating careful selection.

Silicone is often utilized in protective coatings, providing an additional layer of insulation and moisture resistance. Ceramics may also be employed in certain components where high temperature resistance is required. The selection of materials must consider their thermal and electrical properties, ensuring optimal performance in diverse environmental conditions.

4. DESIGN CONSIDERATIONS FOR SOLAR CIRCUIT BOARDS

Designing solar circuit boards necessitates a thorough understanding of photovoltaic systems and their energy management needs. 1. Thermal management, 2. Layout optimization, 3. Component arrangement, and 4. Compliance with industry standards are crucial design aspects.

One of the main challenges with solar circuit boards is thermal management. Since these boards operate in outdoor environments, they are subject to varying temperatures which can impact efficiency. Proper design must account for heat dissipation to prevent overheating, which can lead to failures or reduced performance.

Layout optimization involves strategically placing components to minimize the distance between them, thereby reducing resistance and enhancing efficiency. The arrangement must also incorporate sufficient space for soldering and heat dissipation. Furthermore, compliance with industry standards is essential for ensuring safety and reliability in the end product. Adhering to established norms also facilitates market acceptance, making these boards more appealing to manufacturers and consumers alike.

5. PERFORMANCE OPTIMIZATION IN SOLAR CIRCUIT BOARDS

Enhancing the performance of solar circuit boards involves various techniques and measures aimed at maximizing energy efficiency. 1. Advanced manufacturing techniques, 2. Use of high-quality materials, 3. Testing and validation, and 4. Regular maintenance all play critical roles in achieving optimum performance.

Advanced manufacturing techniques, such as surface mount technology (SMT) and automated assembly processes, improve the precision with which components are placed on the circuit board. These methods are vital in reducing the potential for human error, enhancing overall reliability.

Utilizing high-quality materials and components can significantly impact the performance of solar circuit boards. Investing in better materials may lead to longer lifespans and improved energy efficiency. Furthermore, rigorous testing and validation processes must be undertaken to ensure that every component works seamlessly within the system before it is deployed.

Regular maintenance also contributes to sustaining performance levels for extended periods. Conducting routine checks for wear and damage allows early detection of potential issues, enabling proactive measures to be undertaken before detrimental effects occur.

6. CHALLENGES AND LIMITATIONS OF SOLAR CIRCUIT BOARDS

Despite the many advancements in solar circuit board technology, several challenges and limitations continue to affect their performance and viability. 1. Environmental factors, 2. Technological constraints, 3. Cost considerations, and 4. Market competition are some of the predominant issues faced.

Environmental challenges include exposure to extreme weather conditions, which can lead to physical deterioration of the circuit boards. UV radiation, humidity, and temperature fluctuations can influence the integrity of the materials used, potentially impairing functionality over time.

Technology is constantly evolving, and as such, circuit boards must keep pace with innovations in solar energy systems. The integration of new technologies, such as energy storage solutions and smart grid capabilities, places additional demands on circuit board design. Manufacturers must invest in ongoing research and development to remain competitive while ensuring reliability and efficiency.

Cost considerations also play a significant role in shaping the market for solar circuit boards. Balancing performance with affordability is often a delicate task, as high-quality materials can significantly increase manufacturing costs. Additionally, increasing competition within the industry places further pressure on pricing strategies, compelling manufacturers to be more innovative in their approaches.

7. FUTURE TRENDS IN SOLAR CIRCUIT BOARD TECHNOLOGY

The future of solar circuit board technology promises numerous advancements driven by the growing demand for renewable energy solutions. 1. Integration of AI and IoT, 2. Enhanced materials science, 3. Increased customization capabilities, and 4. Sustainable manufacturing practices are noteworthy trends likely to shape the industry landscape.

The integration of artificial intelligence (AI) and the Internet of Things (IoT) is expected to revolutionize solar circuit board operation. Smart monitoring systems can improve efficiency by analyzing performance data in real-time to optimize energy management. This data-driven approach allows for more informed decision-making regarding energy consumption and storage.

Advancements in materials science are also anticipated to yield improved performance characteristics. Researchers are continually discovering and developing novel materials that exhibit superior properties, such as increased conductivity and enhanced durability. Such materials can lead to more efficient energy transfer and longer-lasting circuit boards.

Increased customization capabilities will allow circuit board manufacturers to design boards tailored to specific applications, accommodating various solar technologies. Moreover, the industry’s focus on sustainability is driving manufacturers to adopt eco-friendly practices in production, leading to reduced environmental impact and a more sustainable future for solar energy technologies.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE MAIN FUNCTIONS OF A SOLAR CIRCUIT BOARD P?

Solar circuit boards perform several essential functions within solar energy systems. The primary role is to facilitate the distribution and regulation of electrical power generated by solar panels. It connects various components, including solar cells, inverters, and batteries. By regulating energy flow, the circuit board ensures optimal performance and efficiency, promoting the effective use of renewable energy. Additionally, these boards often incorporate features for monitoring energy output, enabling users to analyze and improve system performance over time. Overall, the functionalities of solar circuit boards are crucial for the seamless operation of photovoltaic systems, directly impacting energy conversion efficiency.

HOW DO ENVIRONMENTAL FACTORS AFFECT SOLAR CIRCUIT BOARDS?

Environmental factors significantly influence the performance and longevity of solar circuit boards. Exposure to extreme weather conditions, such as high temperatures, humidity, and UV radiation, can lead to material degradation and compromise functionality. For instance, moisture can infiltrate the board, causing corrosion and short-circuiting. Additionally, prolonged exposure to sunlight may affect the insulation properties of materials used in circuit boards, diminishing energy efficiency over time. Manufacturers often incorporate protective coatings and durable materials to address these challenges. Nevertheless, acknowledging the environmental impact is essential for designing reliable solar circuit boards capable of withstanding diverse conditions, ensuring sustained performance throughout their operational lifespan.

WHAT TECHNOLOGICAL ADVANCEMENTS CAN IMPROVE SOLAR CIRCUIT BOARD PERFORMANCE?

Several technological advancements can significantly enhance the performance of solar circuit boards. One crucial area is the development of more efficient manufacturing processes, such as automated assembly techniques and advanced materials. These innovations contribute to improved precision in component placement and reduce the risk of errors during production, leading to higher quality boards. Furthermore, the integration of smart technology, like AI and IoT, allows for real-time monitoring and data analysis, optimizing energy management and system performance. Additionally, ongoing research in materials science has introduced new materials with better conductive properties and increased durability, enabling solar circuit boards to perform more efficiently under various conditions. These advancements collectively foster the growth and efficiency of solar energy systems, promoting broader adoption of renewable energy sources.

The significance of solar circuit board p in contemporary energy solutions cannot be overstated. As the world shifts towards sustainable energy sources, innovation in technology plays a critical role. Emphasizing high-quality materials, efficient designs, and advanced manufacturing techniques enables the development of circuit boards that meet the evolving demands of solar energy applications. Utilities and businesses reliant on renewable energy systems will benefit from investing in these technologies to maximize energy efficiency and reliability. Overcoming challenges such as environmental wear, cost constraints, and technological limitations requires a concerted effort between researchers, manufacturers, and policymakers alike. The future of solar circuit board technology rests upon collaboration and continual improvement, ensuring that solar energy remains a viable alternative to traditional energy sources. By embracing innovations and adopting eco-friendly practices, the circuit board industry can contribute meaningfully to a sustainable future, aligning with global objectives to mitigate climate change and promote responsible energy consumption. Therefore, pursuing advancements in solar circuit board technology is not merely an option; it is imperative for achieving a greener planet.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-is-solar-circuit-board-p/