Silicon serves as a fundamental material in the composition of solar panels, fundamentally influencing their performance and efficiency. 1. Silicon is a key semiconductor used in photovoltaic cells, 2. Its crystalline structure enhances light absorption, 3. Different forms include monocrystalline, polycrystalline, and amorphous silicon, 4. The choice of silicon type affects cost and efficiency. The crystalline structure of silicon significantly enhances the absorption of sunlight. Silicon’s unique properties allow it to efficiently convert solar energy into electricity, making it the most prevalent material in solar technology today.

1. UNDERSTANDING SILICON’S ROLE

Silicon is an elemental substance with the atomic number 14 and lies fourth in abundance in the universe, primarily found in silicates and quartz. It is renowned for its semiconducting properties, making it pivotal in the operation of electronic devices. In solar panels, silicon is essential for converting sunlight into usable energy. The properties of silicon enable it to play a crucial role in the functioning of photovoltaic cells, which are the fundamental components of solar panels.

The semi-conductive nature of silicon allows it to generate electrons when exposed to sunlight. When photons hit the silicon atoms, they transfer energy sufficient to displace electrons, generating a flow of electrical current. This transformation of solar energy into electrical energy is harnessed in applications ranging from powering homes to running spacecraft. Consequently, silicon, in its varied forms, becomes essential for advancing renewable energy technologies and achieving sustainable energy goals across the globe.

2. TYPES OF SILICON IN SOLAR PANELS

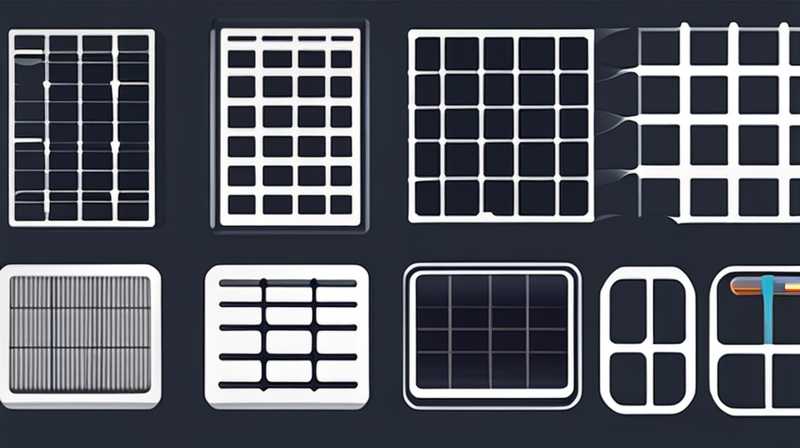

Silicon exists in various forms, each with distinct characteristics suitable for different applications in solar technology. The three primary types of silicon utilized in solar panel manufacture include monocrystalline, polycrystalline, and amorphous silicon. Each type presents unique benefits and drawbacks, influencing their application based on performance requirements and cost constraints. A thorough understanding of these types allows stakeholders to make informed decisions regarding solar panel selection and deployment.

MONOCRYSTALLINE SILICON

Monocrystalline silicon is produced from a single continuous crystal structure, which allows for a highly efficient conversion of solar energy. Photovoltaic cells made from this type of silicon feature a distinctive dark color and rounded edges. One of the primary advantages of monocrystalline silicon is its high efficiency, often exceeding 20%. This efficiency is primarily due to the uniformity of its crystalline structure, which optimally absorbs sunlight and converts it into electrical energy effectively.

However, the production process for monocrystalline silicon is more complex and costly than alternatives. These cells require advanced technology to manufacture, resulting in a higher price point for end consumers. Nonetheless, their durability and performance in varied light conditions make them an attractive choice for many users requiring maximum energy production in limited space. Capacity to perform efficiently in low-light conditions ensures they are sought after for residential installations where space may be at a premium.

POLYCRYSTALLINE SILICON

Polycrystalline silicon is formed from numerous smaller silicon crystals melted together, resulting in a less uniform structure compared to monocrystalline options. In terms of efficiency, polycrystalline solar cells typically achieve around 15-20% effectiveness, making them a viable alternative for users looking for cost-effective solutions. When involved, multipurposed silicon technologies allow for reduced manufacturing costs.

Although slightly less efficient than their monocrystalline counterparts, polycrystalline panels hold several advantages. They exhibit a lower production cost since their manufacturing process is less energy-intensive. These qualities make them popular among consumers who are budget-conscious yet desire substantial energy productivity. In terms of aesthetics, their square appearance with a speckled blue hue may blend more easily into rooflines without drawing undue attention.

AMORPHOUS SILICON

Amorphous silicon (a-Si) resides on the opposite end of the spectrum, as it lacks a crystalline structure, forming a thin film either deposited onto a substrate or built directly into various surfaces. Despite lower efficiency rates, typically between 6-8%, the flexible nature of these panels allows for a diverse range of applications. Amorphous silicon performs well under low-light conditions and can be utilized in portable solar applications, such as chargers for devices.

The primary advantage of amorphous silicon is its versatility, granting integration into products without substantial structural adjustments. However, the energy conversion efficiency remains a significant limitation in its widespread adoption for large-scale solar energy projects. By understanding the diverse characteristics of various silicon types, consumers can determine which panels align best with individual needs, considering factors like available space, budget, and overall energy goals.

3. PRODUCTION AND MANUFACTURING OF SILICON SOLAR PANELS

The production process of silicon solar panels is intricate and begins with silicon extraction from quartz sand, a highly prevalent form of silicon dioxide. The purification process is critical, involving methods such as carbothermic reduction to eliminate impurities and produce metallurgical-grade silicon. Following this, further treatment establishes solar-grade silicon, resulting in a high-purity material essential for effective photovoltaic performance.

Once silicon is purified, two primary forms can be derived: crystalline silicon wafers or thin-film silicon. The crystalline process involves slicing silicon ingots into wafers, necessitating significant precision. Conversely, thin-film technology entails depositing layers of silicon directly onto a substrate, resulting in lightweight and flexible solar products. Understanding these production methodologies is essential as they directly influence the cost, efficiency, and longevity of solar panels, factors paramount in the decision-making process for potential solar energy adopters.

THE IMPACT OF TECHNOLOGICAL ADVANCEMENTS

Technological progress in material science continually influences the efficiency and cost-effectiveness of silicon in solar panels. Innovations such as Passivated Emitter and Rear Cell (PERC) technology significantly enhance the efficiency levels of solar cells by reducing electron recombination losses. As a result, the expansion of PERC technology offers solutions that push cell efficiency above 22%, representing considerable advancements in solar technologies.

Further, ongoing research explores novel variations of silicon to improve performance and longevity. For example, bifacial solar panels leverage both front and rear surfaces for energy collection, essentially doubling the efficiency potential compared to standard panels. These advancements not only lead to performance improvements but also a shift in market dynamics, potentially reducing costs further as technology becomes commonplace.

ENVIRONMENTAL CONSIDERATIONS

The production of silicon solar panels, despite its benefits, raises an important dialogue regarding environmental impact. The extraction and purification process often requires significant energy input and can produce waste materials harmful to ecosystems. Manufacturers are responding by implementing more sustainable practices, such as recycling silicon and minimizing energy use in production facilities.

Innovations in recycling practices are paramount since one of the most significant challenges facing the solar industry today is the end-of-life disposal of solar panels. Initiatives aimed at reclaiming silicon from decommissioned panels can mitigate environmental effects, enhancing sustainability from production to disposal. As awareness grows, efforts to create greener manufacturing processes will be critical for long-term viability and acceptance of solar energy as a key player in renewable resources.

4. THE FUTURE OF SILICON IN SOLAR TECHNOLOGY

The future of silicon in solar technology continues to be bright as the demand for renewable energy sources soars amid climate change concerns. Silicon remains at the forefront due to its well-established properties, infrastructure, and manufacturing capabilities. However, innovation remains essential. Emerging technologies like perovskite solar cells offer potential completions to silicon, promising higher efficiencies and lower production costs.

Moreover, the integration of artificial intelligence and data analytics provides valuable insights for optimizing solar energy solutions. These techniques enable systems to learn and adapt, enhancing efficiency rates and minimizing energy losses. Investing in silicon technology while advocating for interdisciplinary collaboration will be crucial as society seeks robust solutions to contemporary energy challenges.

The transition toward silicon as a central component in solar energy systems highlights its significant role in the quest for sustainable energy solutions. Addressing the intricacies of silicon technology, production processes, and future innovations allows stakeholders to navigate the evolving landscape, ultimately promoting the broad adoption of renewable energy solutions in combating the pressing challenges of climate change.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE ADVANTAGES OF MONOCRYSTALLINE SILICON?

Monocrystalline silicon exhibits notable advantages that contribute to its widespread use in solar panels. The efficiency of monocrystalline solar cells often surpasses 20%, making them among the most effective photovoltaic technologies available. This high efficiency results primarily from the uniform crystalline structure, allowing for optimal energy conversion and absorption of sunlight.

Further, their compact design provides significant output power in limited space, rendering them suitable for residential applications where roof space may be constrained. In addition to efficiency, monocrystalline panels offer durability and longevity; they often come with warranties spanning up to 25 years. This reliability equates to a solid investment for consumers seeking a dependable energy source.

Despite the higher initial costs associated with monocrystalline panels, the long-term efficiency and savings on energy bills typically justify the investment. Choosing monocrystalline silicon thus reflects a choice for premium performance, demonstrating that while upfront costs may be higher, potential energy savings and consistent performance provide substantial benefits over the lifespan of the panels.

HOW DOES POLYCRYSTALLINE SILICON DIFFER FROM MONOCRYSTALLINE SILICON?

Polycrystalline silicon differs fundamentally from monocrystalline silicon in its manufacturing process and overall performance characteristics. Whereas monocrystalline silicon cells are created from a single silicon crystal, leading to a more uniform and efficient energy conversion, polycrystalline cells are produced from multiple silicon crystals melted and cooled together. This difference in crystallinity significantly impacts efficiency, with polycrystalline cells generally achieving efficiencies between 15-20%.

In terms of appearance, polycrystalline cells feature a speckled blue color and are typically less expensive to manufacture than their monocrystalline counterparts. This affordability makes polycrystalline silicon panels a more budget-friendly option while still providing considerable energy output. Despite their lower efficiency, polycrystalline panels hold effectiveness for many consumers, particularly in spaces that can accommodate larger installations that utilize multiple panels to achieve desired energy production.

The choice between polycrystalline and monocrystalline silicon ultimately boils down to budget, installation space, and performance requirements. Consumers prioritizing efficiency may opt for monocrystalline cells, while those seeking more flexible, cost-effective solutions may gravitate toward polycrystalline options, reflecting a balance between capital investment and energy outcomes.

WHAT ARE THE ENVIRONMENTAL IMPACTS OF SILICON PRODUCTION?

The environmental impact of silicon production is a critical aspect of renewable energy discussions. Extracting silicon primarily involves mining quartz sand, leading to habitat disruption and possible ecosystem degradation. Additionally, the purification process consumes vast amounts of energy, raising concerns related to carbon emissions generated during manufacturing.

Despite these issues, many manufacturers are adopting sustainable practices to mitigate negative environmental effects. Efforts include minimizing energy use, implementing waste recycling processes, and exploring greener alternatives in each production stage. Innovations in recycling technologies will also play a vital role in determining the long-term sustainability of silicon. By reclaiming materials from decommissioned solar panels, the solar energy sector can address end-of-life disposal challenges and reduce resource consumption associated with newly extracted silicon.

As the solar energy market evolves, balancing technological advancements and environmental responsibility will be critical for the industry’s sustainability trajectory. Establishing a circular economy through recycling and efficient manufacturing will ensure that the environmental footprint associated with silicon production becomes progressively manageable, fostering a healthier planet while facilitating renewable energy expansion.

The discussion surrounding silicon, especially in the context of solar panels, plays a pivotal role in a transformative energy landscape. Given its unique properties, silicon stands as a linchpin in modern photovoltaic technology, consistently driving innovation toward more efficient solar energy solutions. As societies worldwide strive to embrace renewable energy, the importance of silicon remains unquestionable. By optimizing the advantages of different silicon types while advancing sustainable production practices, the energy sector is positioned to rise to environmental challenges. Through a combination of material sciences, innovative technologies, and sustainable practices, silicon’s enduring relevance in solar technologies will profoundly shape the progression of global energy systems.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-is-silicon-in-solar-panels/