Energy storage equipment manufacturing involves the design, production, and assembly of devices that store energy for later use, including batteries, supercapacitors, and flywheels. 1. This field is essential for optimizing energy distribution and usage, 2. it supports renewable energy integration, 3. and it enhances grid stability and resilience. The growing demand for energy storage solutions is driven by the need for reliable, efficient, and sustainable energy systems. Manufacturing processes encompass a range of technologies, materials, and applications, resulting in diverse energy storage products tailored for residential, commercial, and industrial use. One aspect that warrants attention is the significant role advanced materials play in enhancing battery performance. New developments in materials science lead to improvements in energy density, lifespan, and environmental sustainability, offering more efficient energy storage solutions.

1. UNDERSTANDING ENERGY STORAGE

The landscape of energy storage has evolved significantly in recent years, influenced by technological advancements and the necessity for more sustainable energy sources. At its core, energy storage encompasses various technologies that capture and retain energy for later use. Understanding the fundamental principles behind energy storage is pivotal for both manufacturers and consumers. From a technical perspective, energy storage allows users to store excess energy produced during peak generation times and utilize it during periods of high demand or production shortfalls.

Energy storage systems are instrumental in balancing supply and demand on the electrical grid. They facilitate the smooth integration of renewable energy sources, such as wind and solar, which operate intermittently. By storing energy when production exceeds demand and supplying it back to the grid when demand peaks, energy storage systems enhance grid reliability and reduce the need for costly peaking power plants.

2. MANUFACTURING TECHNOLOGIES IN ENERGY STORAGE

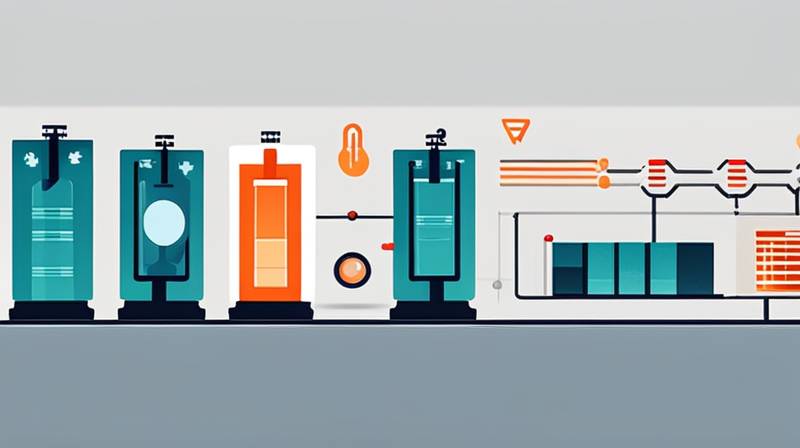

Diverse technologies are employed in the manufacturing of energy storage equipment, each with unique methodologies and applications. The most prevalent forms include traditional batteries, flow batteries, supercapacitors, and mechanical systems. Each technology has distinct characteristics that cater to various energy storage requirements, making it imperative for manufacturers to have a comprehensive understanding of these systems.

For various applications, traditional battery technologies, like lithium-ion, lead-acid, and nickel-metal hydride, dominate the market. Lithium-ion batteries, in particular, have witnessed exponential growth due to their high energy density, efficiency, and declining costs. However, as demand rises and sustainability concerns increase, alternative battery technologies are gaining traction. For instance, flow batteries, characterized by their scalability and long cycle life, offer an attractive solution for large-scale energy storage applications, catering particularly well to renewable energy sources.

3. MATERIALS AND THEIR IMPACT ON PERFORMANCE

The choice of materials used in energy storage equipment directly influences performance characteristics such as energy density, efficiency, and lifespan. Research and development efforts are increasingly focused on advanced materials that can enhance the capabilities of energy storage systems. For example, innovative anode and cathode materials can significantly improve energy storage efficiency, leading to better battery performance and longevity.

Graphene, silicon composites, and nickel-rich materials have emerged as potential game-changers in energy storage technology. These materials hold the promise of higher capacity and faster charging times, creating new opportunities for industries reliant on efficient energy storage solutions. Furthermore, the exploration of sustainable materials is becoming crucial as manufacturers seek to reduce the environmental footprint of their products. Enhanced recycling methods for existing materials exacerbate the need for a sustainable lifecycle approach to energy storage equipment.

4. REGULATORY ENVIRONMENT AND MARKET DEMANDS

The energy storage market operates within a complex regulatory environment that influences manufacturing practices and product development. Various policies and regulations have been implemented globally to foster the development of renewable energy technologies and energy storage systems. Understanding the implications of these regulations is fundamental to navigating successfully through the energy storage landscape as a manufacturer or investor.

Market demands continue to evolve, driven by factors such as technological advancements, the push for carbon neutrality, and increasing consumer awareness regarding sustainable energy solutions. Manufacturers must adapt to changing consumer expectations while ensuring compliance with regulatory requirements. Innovations like smart grid technologies and demand response programs further enhance the necessity for efficient energy storage solutions, presenting lucrative opportunities for manufacturers capable of meeting these requirements.

5. FUTURE TRENDS IN ENERGY STORAGE

As technology progresses and society shifts toward sustainable energy, energy storage equipment manufacturing is poised for transformative changes. Emerging trends include advancements in solid-state battery technology, increased automation in manufacturing processes, and the integration of AI-driven analytics to optimize energy storage performance. The rise of smart homes and electric vehicles reinforces the demand for efficient, scalable energy storage solutions.

Moreover, understanding end-user needs will drive innovation in product offerings. Consumers are increasingly looking for user-friendly systems that integrate seamlessly with existing energy infrastructure. Therefore, energy storage manufacturers must prioritize designing adaptive, smart equipment that caters to market complexity while reducing environmental impact.

FREQUENTLY ASKED QUESTIONS

WHAT TYPES OF ENERGY STORAGE EQUIPMENT ARE COMMONLY MANUFACTURED?

Energy storage equipment encompasses a variety of devices, primarily batteries, supercapacitors, and mechanical systems. Batteries, particularly lithium-ion, are the most prevalent, utilized predominantly in household electronics and electric vehicles due to their high energy density and efficiency. Flow batteries serve well for large-scale energy storage applications, such as grid stabilization, due to their scalability and long discharge durations. Supercapacitors, on the other hand, are optimized for quick burst power applications, ideal for regenerative braking in electric vehicles or high-power industrial uses. Mechanical systems like flywheels and pumped hydro storage provide bulk storage and are integral to grid management, capable of storing and releasing energy swiftly, thus contributing to overall stability in energy supply.

HOW DOES ENERGY STORAGE EQUIPMENT BENEFIT RENEWABLE ENERGY USAGE?

Energy storage plays a crucial role in harnessing renewable energy effectively. Due to the intermittent nature of sources like solar and wind, energy storage systems allow excess energy to be captured and stored, then redistributed when generation falls short. This capability ensures a continuous power supply, increasing reliability and availability for consumers while reducing dependency on non-renewable energy sources. For instance, during sunny hours, solar systems can generate surplus energy, which is stored and utilized during cloudy periods or at night, thus optimizing energy use. Furthermore, these systems enable grid operators to manage demand fluctuations without resorting to fossil fuels, supporting the overall transition towards a sustainable energy future.

WHAT ARE THE CHALLENGES FACING ENERGY STORAGE EQUIPMENT MANUFACTURING?

Manufacturing energy storage equipment entails navigating multiple challenges, primarily related to technological, material, and economic factors. One significant hurdle is the rapid pace of technology development, which requires manufacturers to continuously innovate and adapt to stay competitive. The reliance on rare materials in batteries raises concerns regarding supply chain stability and environmental impact, pushing companies to explore alternative resources and sustainable practices. Additionally, financing these technologies can be challenging, as potential clients may be reluctant to invest in systems without established performance records or clear economic benefits. Thus, the ability to address these concerns through transparent reporting and robust product performance data is critical for manufacturers aiming to capture market share in the energy storage sector.

The advancement of energy storage equipment manufacturing represents a crucial element in addressing today’s energy challenges, catalyzing a revolution in how energy is stored and utilized. As society pivots towards sustainable and reliable energy sources, manufacturers play an essential role, adapting to emerging technologies, optimizing processes, and meeting consumer demands while ensuring regulatory compliance. It is evident that the sector remains dynamic, presenting vast opportunities for innovation and growth. The landscape is enriched by ongoing research into materials, system designs, and integration strategies, enhancing the reliability and performance of energy storage solutions. With the global focus on sustainability, collaboration across industries and government initiatives will further propel advancements in energy storage technologies.

Efforts to streamline manufacturing processes and reduce costs will be pivotal in shaping the future landscape. As renewable energy sources become more predominant, the role of energy storage systems becomes increasingly significant in transitioning to a low-carbon economy. Emphasizing environmental sustainability and lifecycle considerations will steer the course for not only the energy sector but also the broader context of manufacturing and technology development. Thus, stakeholders must remain vigilant, engaging in continuous learning and adaptation to ensure the successful evolution of energy storage equipment manufacturing in the coming years.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-is-energy-storage-equipment-manufacturing/