1. Energy storage battery assembly is a process that encompasses the design, construction, and integration of energy storage systems in order to efficiently store and manage electrical energy. 2. This assembly plays a pivotal role in renewable energy applications, enhancing the efficiency and reliability of battery systems. 3. By facilitating energy grid stability, energy storage battery assemblies enable the integration of intermittent power sources such as solar and wind. 4. The manufacturing involves various components such as cells, modules, and management systems that ensure optimal performance. 5. Detailed attention to quality control and safety regulations is critical in the assembly process to prevent hazards and maximize longevity.

1. UNDERSTANDING ENERGY STORAGE BATTERY ASSEMBLY

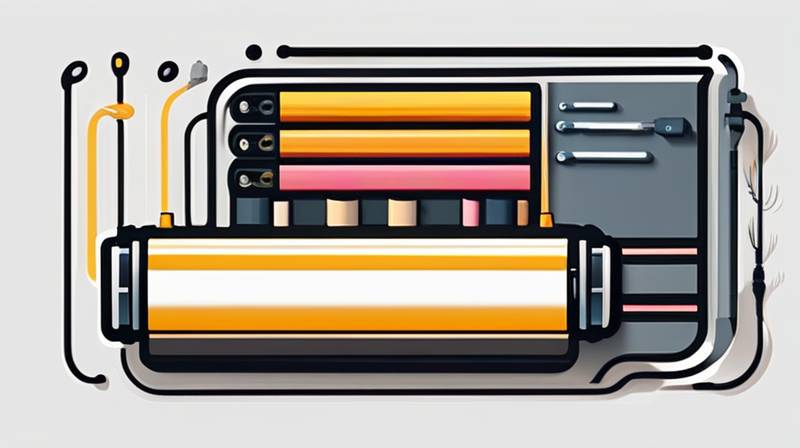

Energy storage battery assembly represents not just a technological endeavor, but a critical response to the evolving needs of modern energy demands. This assembly process involves multiple intricate stages, where raw materials transform into sophisticated systems capable of storing electricity for later use. Essentially, these battery systems serve as crucial intermediate solutions that enhance the overall efficiency of power consumption. By understanding the structural and functional components of energy storage systems, one can appreciate their pivotal role in both residential and commercial sectors.

In light of rising energy costs and increasing environmental concerns, businesses and households alike are recognizing the importance of robust battery systems. Such systems enable users to store surplus energy generated during peak production times and utilize it during periods of demand. The assembly of these batteries often involves selecting various types of cells, manage their integration, and ensuring the longevity and safety of the final product. Through this discussion, one gains insight into the specialized processes backing the production of energy storage batteries and their implications in contemporary society.

2. COMPONENTS OF ENERGY STORAGE BATTERY ASSEMBLY

To grasp the intricacies of energy storage battery assembly, it is essential to delve deeply into the various components that facilitate the storage and retrieval of energy. At the core, battery cells act as the fundamental units of energy storage, varying widely in type, such as Lithium-ion, Lead-acid, or Flow batteries. Each type of cell offers distinct advantages and drawbacks, influencing the overall system performance.

Lithium-ion batteries, for instance, are favored for their high energy density, leading to lighter structures and longer life cycles. However, they do come with challenges, such as the necessity for complex battery management systems to monitor the charge and health of each cell. By contrast, Lead-acid batteries are robust and cost-effective, yet they present limitations in energy density and life span. The choice of cells directly affects the design criteria for the battery assembly.

Apart from the cells, battery modules form the next layer of the assembly. These modules consist of multiple cells working in tandem, aimed to meet specific voltage and capacity requirements. It is within the modules that intricate arrangements and connections occur, necessitating a keen focus on thermal management and electrical efficiency. Effective thermal management is imperative for safety, as overheating can lead to decreased performance or even catastrophic failures.

3. THE ASSEMBLY PROCESS

Diving deeper into the assembly process, it becomes clear that it embodies not only mechanical work but also advanced engineering insights. The process typically commences with the purchase and preparation of components, where quality assurance checks are a priority, ensuring that all materials meet stringent safety and performance standards.

After components are prepared, the assembly line begins the integration of battery cells into modules. This stage involves meticulous attention to detail, as any variance in assembly can lead to inefficiencies or hazardous failures. Balancing the cells within a module so that they charge and discharge at uniform rates is critical as inconsistency can lead to reduced battery life or battery management issues.

An equally significant aspect of the assembly lies in the incorporation of the battery management system (BMS). The BMS is a sophisticated tool that monitors each cell’s voltage, temperature, and current while providing essential protection against overcharging, deep discharging, and short-circuiting. The effective integration of the BMS into modules can vastly improve the performance and safety of the battery system.

4. QUALITY CONTROL AND SAFETY MEASURES

Ensuring quality and safety is paramount throughout the assembly process. Regular inspections at various stages of production are necessary to safeguard the integrity of the battery systems. Advanced testing protocols examine individual cells for defects, ensuring that only the highest quality components are used in the assembly.

Furthermore, safety measures must extend beyond component quality to encompass the environment in which assembly occurs. Controlled environments help minimize contaminants that may affect the integrity of battery materials. Workers must adhere to strict protocols to handle potentially hazardous materials safely, especially during the assembly and testing stages.

Comprehensive safety regulations set forth by organizations and governmental bodies must be integrated into all assembly procedures to minimize risks. Training for assembly workers on safe practices and emergency protocols can mitigate potential hazards, ensuring both worker safety and product reliability.

5. APPLICATIONS OF ENERGY STORAGE BATTERY ASSEMBLY

Energy storage battery assemblies are revolutionizing numerous sectors, with applications ranging from renewable energy integration and electric vehicle technology to utility-scale energy management. The most prevailing use case centers around renewable energy, where these systems bridge the gap between energy generation and consumption.

For instance, solar panels generate electricity during daylight hours, whereas energy demand often peaks in the evening. Here, a well-assembled energy storage system can store daytime surplus energy and release it during peak use, optimizing energy utilization and enhancing grid reliability. This ability to respond dynamically to fluctuating energy supply and demand is crucial for the ongoing transition towards a sustainable energy landscape.

Additionally, in the automotive sector, electric vehicles leverage advanced energy storage assemblies to maximize range and performance. As the demand for electric vehicles grows, the development of lighter and more efficient energy storage solutions remains at the forefront of engineering efforts. Innovations in battery chemistry and modular assembly techniques are vital for meeting these evolving demands.

6. CHALLENGES AND FUTURE DIRECTIONS

Despite the numerous advantages associated with energy storage battery assembly, challenges abound that necessitate ongoing research and innovation. Issues related to resource depletion for components, particularly with materials like lithium and cobalt, pose significant concerns about sustainability in the long term. Sourcing these materials ethically and developing recyclable options for spent batteries are essential moving forwards.

In parallel, the quest for improved battery performance drives innovation in cell chemistry, with notable focus on alternatives to lithium-ion technologies, such as solid-state batteries and new chemistries promising enhanced safety and efficiency. Research is also delving into integrating energy storage solutions with advanced grid technologies to commune distributed energy resources seamlessly.

As needs evolve, the energy storage battery assembly landscape will continue to transform, adopting new metrics of efficiency, safety, and environmental responsibility in alignment with global energy initiatives. Addressing these challenges paves the way for a robust and sustainable energy future.

7. THE ROLE OF REGULATIONS AND STANDARDS

The landscape of energy storage battery assembly is heavily influenced by regulations and standards established by national and international agencies. These standards govern every aspect of the assembly process from manufacturing practices to safety protocols. Compliance with these standards ensures that batteries are built to withstand rigorous testing and real-world application scenarios.

International guidelines, such as those set by the International Electrotechnical Commission (IEC), dictate the safety criteria for battery performance. Manufacturers must incorporate testing procedures that comply with these guidelines to validate the reliability of their products. Adherence to established standards not only secures product integrity but also enhances consumer trust in energy storage solutions.

Navigating the regulatory environment can be complex and requires ongoing education and training for manufacturers. However, ensuring compliance is tantamount to reducing risks associated with battery failures and accidents, which can potentially have dire consequences. By embedding these regulations within the assembly practices, the industry can look forward to a safer and more efficient future.

8. ECONOMIC IMPACT OF ENERGY STORAGE BATTERY ASSEMBLY

The economic implications of energy storage battery assembly resonate across multiple sectors, highlighting its significance in job creation, technological advancements, and market transformation. The emergence of this field has resulted in a growing demand for skilled labor tailored to the intricacies of battery design and assembly. This demand spurs the development of specialized training programs, contributing to workforce growth.

Moreover, the shift towards renewable energy and energy storage solutions has catalyzed investments in research and development. Governments and private entities are recognizing the economic benefits linked to enhancing energy efficiency through battery systems. This is further evidenced by the proliferation of startup companies developing innovative storage technologies, promising to advance energy efficiency and open up new markets.

The ability of energy storage systems to lower energy costs for consumers adds another layer to its economic impact. By enabling users to take advantage of off-peak energy rates or moderate peak consumption, these systems are becoming increasingly appealing for both residential and commercial setups.

QUESTIONS TO CONSIDER

WHAT ARE THE BENEFITS OF ENERGY STORAGE BATTERY ASSEMBLY?

Energy storage battery assembly presents myriad benefits, contributing significantly to energy management strategies in various settings. Beyond providing backup power solutions during outages, these systems enhance grid reliability by accommodating variations in energy supply and demand. Energy storage systems allow renewable resources like solar and wind to be harnessed efficiently, reducing dependency on fossil fuels. Furthermore, businesses can leverage energy storage to optimize operational costs through participation in demand response programs, garnering financial incentives for moderated energy usage.

HOW DOES ENERGY STORAGE SYSTEM INTEGRATION WORK?

Integration of energy storage systems into existing infrastructure involves a strategic assessment of energy needs and consumption patterns. Stakeholders must evaluate site-specific factors such as energy production, local regulations, and environmental conditions. Through the integration of smart technologies, these systems can communicate with grid operators, enabling real-time data exchange that allows for efficient energy management. The successful integration requires a well-designed framework utilizing advanced control mechanisms, ensuring optimal energy flow while maintaining safety and reliability.

WHAT ARE THE SAFETY MEASURES IN ENERGY STORAGE BATTERY ASSEMBLY?

Safety measures in energy storage battery assembly are critical in safeguarding both the product and individuals involved in the assembly process. Manufacturers are compelled to adhere to rigorous safety protocols and implement standard operational procedures designed to mitigate hazards associated with battery materials. Comprehensive risk assessments must analyze potential failure modes and establish contingencies to address emergencies. Additionally, training employees on safe handling and operation procedures reinforces a safety culture, minimizing risks of accidents during production and enhancing overall safety performance.

In summary, energy storage battery assembly encompasses complex multi-faceted processes critical to modern energy management. These systems not only provide reliable energy solutions but also foster advancements in technology and sustainability efforts. Addressing the growing need for efficient energy storage is vital as we transition toward greener sources of energy. As innovations continue to shape this sector, understanding the integral components and assembly processes will be paramount for stakeholders aiming to optimize energy systems. The combination of careful design, stringent regulatory compliance, and progressive engineering approaches will ultimately dictate the future success of energy storage solutions. Moreover, staying attuned to market dynamics will ensure that energy storage battery assemblies remain at the forefront of energy management strategies, offering not just a safety net during energy shortages, but a transformative approach towards a more resilient energy landscape.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-is-energy-storage-battery-assembly/