A flywheel energy storage motor is a mechanical device employing a rotating mass to store energy kinetically, implementing principles of inertia and angular momentum. 1. This system provides a means for energy storage that allows for quick energy release, making it beneficial for applications requiring high power and fast response times, such as in frequency regulation within electrical grids. 2. Flywheel systems can achieve high efficiency and have longevity due to lower wear compared to chemical batteries or capacitors. 3. These systems often employ advanced materials to minimize energy losses through friction and air resistance. 4. Moreover, flywheel energy storage is evolving as a pivotal technology in smart grids and renewable energy integration, standing out for its sustainability and environmental benefits.

1. UNDERSTANDING FLYWHEEL ENERGY STORAGE

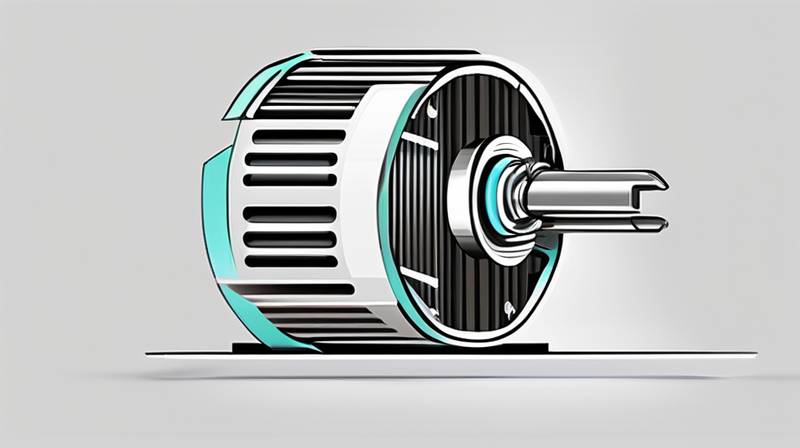

Flywheel energy storage systems have emerged as innovative solutions for energy retention and distribution. The core concept revolves around mechanical energy storage, where energy is stored in the form of kinetic energy through the rotation of a large wheel or rotor. The design and engineering of these systems allow for rapid energy release and efficient operational dynamics.

In essence, when excess energy is available, typically sourced from renewable systems like solar or wind, it is converted into kinetic energy by accelerating the flywheel. During periods of high demand or energy deficit, this stored kinetic energy can be transformed back into electrical energy. This reversible process underlines the broader applicability of flywheels, extending beyond mere mechanical systems to encompass complex energy management systems.

The operational efficiency of flywheel systems is often highlighted by their ability to achieve nearly 95% round-trip efficiency, making them vastly superior to conventional battery systems in certain applications. Moreover, the lifespan of a flywheel, often exceeding 20 years, significantly reduces the need for replacement and maintenance, marking a paradigm shift in energy storage technologies.

2. WORKING MECHANISM OF FLYWHEEL ENERGY STORAGE SYSTEMS

Deepening our understanding of the underlying mechanisms of flywheel energy storage systems reveals intricate engineering principles at play. The flywheel itself consists of a robust rotor, which is engineered from materials designed to withstand extreme rotational stress and minimize energy loss. High-strength composites or metals are often used due to their light weight and durability.

Energy storage and release occur through a conversion process involving electrical energy transformed into kinetic energy via a motor-generator system. When the flywheel accelerates, it stores mechanical energy until required, at which point the kinetic energy is converted back into electrical energy. This conversion occurs within milliseconds, facilitating rapid response to demand fluctuations. The efficiency of the motor-generator unit is paramount; they must be optimized for performance to ensure there is minimal energy loss in the process.

A significant aspect of the technology is the vacuum-sealed environment in which many flywheel systems operate. This arrangement minimizes air resistance, enabling the flywheel to maintain higher speeds with lower energy consumption. Additionally, bearings technology has also seen improvements, with magnetic and air bearings being employed to reduce friction, enhancing longevity and performance.

3. APPLICATIONS OF FLYWHEEL ENERGY STORAGE

Flywheel energy storage technologies are becoming increasingly relevant across diverse sectors. Particularly noteworthy is their role in renewable energy integration, where they provide critical support in managing intermittency inherent in wind and solar power generation. By acting as a buffer, flywheel systems can store excess energy produced during peak generation times and release it during periods of low production.

In power grid management, flywheels contribute to frequency regulation. Power grids require a delicate balance between energy supply and demand, with fluctuations potentially leading to instability. Flywheels are adept at responding to these fluctuations, delivering bursts of power instantaneously to balance the grid’s frequency. This capability is particularly essential for regions with high renewable energy contributions, where supply variations are common.

On a commercial scale, industries have increasingly turned to flywheel systems for uninterrupted power supply (UPS) systems. Traditional UPS solutions utilizing chemical batteries can suffer from degradation over time, impacting reliability. Flywheels, with their notable lifespan and rapid response times, offer a superior alternative for maintaining power during outages, especially in critical sectors such as data centers and healthcare facilities.

4. ENVIRONMENTAL IMPACT OF FLYWHEEL ENERGY STORAGE

An increasingly pivotal consideration in today’s energy landscape is the environmental footprint of energy storage technologies. Compared to conventional batteries, flywheels present a more sustainable alternative, mainly due to the materials used and the absence of hazardous elements. The lifecycle emissions associated with flywheel systems are considerably lower, aligning with global sustainability goals.

The production processes for flywheels also reflect a reduced environmental impact. Many manufacturers emphasize using recyclable materials, which contributes to a lower overall carbon footprint. When decommissioned, the components of flywheel systems can often be repurposed or recycled, thereby mitigating waste associated with traditional energy storage solutions.

Furthermore, by enabling greater integration of renewable energy sources, flywheel systems facilitate the transition to a lower-carbon energy future. As more systems are deployed, they play a vital role in stabilizing the grid against disturbances, ultimately aiding in the reduction of reliance on fossil fuels and transitioning to greener solutions.

5. CHALLENGES AND FUTURE OUTLOOK

Despite the myriad benefits flywheel energy storage technologies offer, they are not devoid of challenges. As with any technology, scaling up and improving cost-effectiveness remains paramount. Flywheels currently have a higher upfront cost compared to other forms of energy storage, such as lithium-ion batteries. However, their low operational costs over time can offset these initial investment hurdles.

Another challenge lies in the potential physical hazards associated with high-speed rotation. Depending on design, failures can result in catastrophic outcomes if not managed correctly. Therefore, continued innovation in materials and engineering design is necessary to ensure safety while enhancing performance.

As the global shift toward renewable energy accelerates, the future of flywheel energy storage appears promising. Ongoing research aims to optimize existing technologies and explore new applications, particularly in electric vehicles and grid-scale installations. With the push for smarter grids and cleaner energy, the evolution of flywheel systems holds substantial potential to contribute to a sustainable energy landscape.

FLYWHEEL ENERGY STORAGE FAQS

WHAT ARE THE ADVANTAGES OF FLYWHEEL ENERGY STORAGE OVER BATTERY STORAGE?

Flywheel energy storage systems present numerous advantages compared to conventional battery technologies. Key among these benefits is longevity; flywheels typically have lifespans extending beyond 20 years with minimal performance degradation, whereas batteries often require replacement every few years. This longevity contributes to lower lifetime costs despite the initial investment being higher.

Efficiency is another cornerstone of flywheel technology, boasting round-trip efficiencies of up to 95%. This makes them significantly more profitable over time, particularly in applications where rapid energy discharge and recharge cycles are necessary. Furthermore, flywheels can deliver power almost instantaneously, making them ideal for balancing supply with demand on rapidly fluctuating energy grids.

Additionally, the environmental impact of flywheels is considerably lower, given that they use recyclable materials and do not involve hazardous substances typical of battery systems. This makes flywheels an attractive option in the face of growing environmental concerns.

HOW DOES A FLYWHEEL MAINTAIN ENERGY STORAGE?

The operational premise of a flywheel energy storage system rests on maintaining energy storage via kinetic energy. The flywheel spins at high speeds within a vacuum environment to limit friction and air resistance. This operational framework allows the device to hold energy as long as it continues to spin without significant loss.

Additionally, advanced bearings, often magnetic or air-based, minimize friction further and enhance the lifetime of the system. As the flywheel continues to rotate, any perturbation in speed can be compensated for by either inputting more energy or utilizing the kinetic energy for power output.

The meticulous engineering of flywheel systems is essential in ensuring they can meet the demands placed on them, particularly in applications requiring swift responses to changing energy needs. A flywheel system can maintain its mechanical energy indefinitely if managed adequately, ready to release it whenever needed.

WHAT ARE THE LIMITATIONS OF FLYWHEEL ENERGY STORAGE?

While flywheel energy storage systems offer considerable advantages, they also exhibit certain limitations. One significant challenge lies in their initial costs. The upfront investment for a flywheel system can be considerably higher than other energy storage alternatives, primarily due to the advanced materials and engineering processes required to manufacture and deploy them.

Another limitation is energy density. Flywheels typically store less energy per unit weight than batteries; therefore, while they excel in rapid discharge scenarios, they might not be the best option for long-term energy storage needs. This difference in energy capacity can restrict their application scope, particularly in scenarios where bulk energy storage is a priority.

Furthermore, the safety considerations surrounding high-speed mechanical systems necessitate careful design and operational guidelines. Any malfunction can lead to catastrophic results, although advances in material science and engineering continue to improve operational safety.

Flywheel energy storage motors represent an innovative advancement in energy storage, merging efficiency with sustainability for various applications. This technology harnesses kinetic energy in a mechanical form, redefining energy management capabilities. Key advantages include longevity, efficiency, and minimal environmental footprint, contributing significantly to modern energy systems, particularly as society transitions to renewables. Rapid energy discharge capabilities make flywheels indispensable for balancing grid demands, while their durability translates to lower lifecycle costs. However, challenges persist, primarily concerning initial costs and safety considerations. Ensuring the reliability and safety of such systems is crucial as technology evolves. As the global energy landscape continues to prioritize sustainable solutions, the relevance of flywheel energy storage becomes increasingly pronounced, positioning it as a frontrunner in the quest for modern, efficient energy infrastructure. Continued research and development will likely enhance its capabilities, allowing for even broader integration and application across various sectors. This development trajectory promises to make flywheel systems an integral element of future energy solutions, underscoring the importance of innovation in meeting global energy challenges.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-is-a-flywheel-energy-storage-motor/