A factory energy storage project refers to a system designed to store energy for later use, primarily utilizing renewable sources for efficiency and sustainability. 1. These projects aim to enhance energy efficiency, thereby reducing operational costs and reliance on fossil fuels. 2. They integrate various technologies, such as batteries and thermal storage systems, which are crucial in stabilizing energy supply. 3. The shift towards such projects correlates with increasing demand for cleaner energy solutions, making them relevant in today’s industrial landscape. 4. Implementation challenges exist, such as costs and regulatory compliance, yet the benefits of increased resilience and independence from grid fluctuations make them a vital consideration for future industrial strategies. For instance, the stored energy can be utilized during peak demand periods, ensuring a more balanced load and improved grid stability. Such projects not only promote environmental stewardship but also enhance operational reliability, proving instrumental in the transition to a more sustainable energy paradigm.

1. UNDERSTANDING FACTORY ENERGY STORAGE PROJECTS

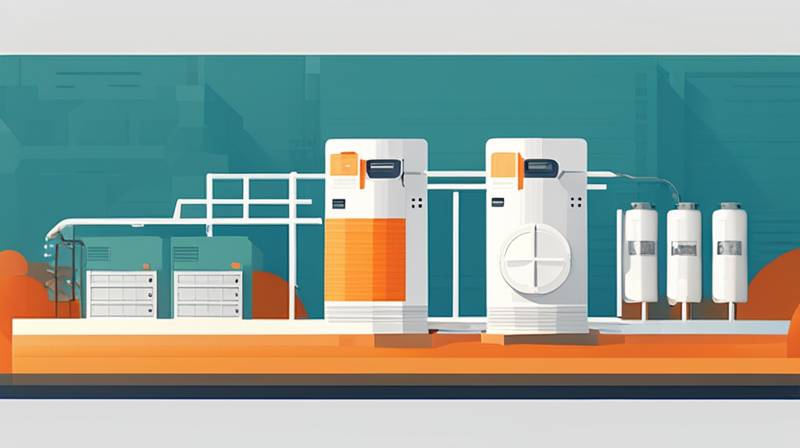

In recent years, the urgency for energy innovation has surged substantially. The concept of factory energy storage projects is not merely a trend; it embodies a sophisticated blend of technology, strategy, and sustainability, aimed at revolutionizing the industries. As factories grapple with rising energy costs and environmental concerns, energy storage systems emerge as pivotal solutions. This realm includes technologies designed to capture surplus energy, often generated from renewable sources like solar or wind, for later use.

The underlying mechanism of these storage projects is substantial. They allow factories to optimize their energy consumption by storing excess energy produced during low demand periods. Subsequently, this stored energy can be used when demand spikes or during peak hours when energy costs are exorbitant. Notably, such strategic energy management not only contributes to lowering costs but also reduces the carbon footprint of manufacturing processes.

2. TECHNOLOGIES INVOLVED IN ENERGY STORAGE

Numerous technologies facilitate energy storage in industrial settings, with battery storage being the most recognized. Lithium-ion batteries, for instance, dominate the storage landscape due to their energy density and efficiency. These batteries are employed to store energy generated during off-peak hours, providing a buffer against fluctuating electricity rates. They function by converting electrical energy into chemical energy, which can be reclaimed when required. However, the evolution of battery technologies is not limited to lithium-ion.

Flow batteries, compressed air energy storage, and thermal energy storage systems also play significant roles. Flow batteries, for example, utilize liquid electrolytes to store energy, presenting advantages such as longer life cycle and scalability. Compressed air storage captures excess energy in the form of compressed air stored in underground caverns, which can be released to generate electricity when needed. Conversely, thermal storage systems harness energy by heating or cooling materials, allowing factories to tap into energy when thermal loads peak. Each technology comes with unique benefits and challenges, and a thorough analysis can help factories determine the most suitable storage solution for their operational needs.

3. ECONOMIC IMPACTS OF ENERGY STORAGE

The economic implications of implementing factory energy storage extend far beyond initial investment considerations. Understanding how these projects affect bottom lines requires an in-depth examination of cost structures. Firstly, energy storage helps businesses mitigate peak demand charges, which often constitute a significant portion of a factory’s utility bill. By strategically discharging stored energy during peak periods, facilities can avoid high rates associated with excessive usage.

Additionally, these systems promote energy independence, drastically reducing reliance on grid power, particularly during instances of outages or energy price spikes. This independence can translate into increased operational flexibility and enhanced capacity to respond to market fluctuations. Further, implementing energy storage aligns with conservation efforts, often yielding incentives such as tax credits and rebates offered by governmental bodies. Such financial advantages, combined with the reduced operational costs, create a compelling narrative for factories considering this technology amidst fluctuating energy environments.

4. ENVIRONMENTAL BENEFITS OF ENERGY STORAGE

An often-overlooked facet of factory energy storage projects is their substantial contribution to environmental sustainability. Transitioning away from fossil fuels is crucial in combating climate change, making energy storage integral to adopting renewable energy sources. By facilitating the integration of solar and wind energy, storage technologies enable factories to utilize cleaner energy while mitigating dependence on conventional power sources.

In addition to advancing renewable integration, energy storage systems reduce greenhouse gas emissions associated with manufacturing processes. By optimizing energy usage and minimizing carbon footprints, factories can play a pivotal role in achieving sustainability goals. Furthermore, these systems often contribute to a more resilient energy grid, enhancing sustainability in regional energy supply while lessening the impact of energy fluctuations on broader environmental systems.

5. CHALLENGES IN IMPLEMENTING ENERGY STORAGE PROJECTS

Despite the evident advantages, numerous challenges hinder the widespread adoption of factory energy storage projects. One significant hurdle is the initial capital investment required to implement advanced energy storage systems. Many factories face difficulties when it comes to allocating budgetary resources for such initiatives, especially in environments characterized by thin margins and intense competition.

In tandem, regulatory and policy barriers also pose challenges. Navigating through local, state, and federal regulations can be cumbersome, and discrepancies in policies can deter manufacturers from investing in such technologies. Compliance with evolving standards adds another layer of complication. However, overcoming these challenges requires robust planning, strategic partnerships with technology providers, and proactive engagement with policymakers to create a conducive environment for energy storage adoption across the manufacturing sector.

6. SUCCESS STORIES AND CASE STUDIES

Examining successful implementations of factory energy storage projects can provide valuable insights and inspiration. For instance, consider a major automotive manufacturing plant that invested in a lithium-ion battery storage system. By storing excess solar energy generated during daytime hours, the facility was able to reduce its energy costs significantly. Furthermore, the plant utilized the stored energy during high-demand periods, leading to substantial savings that bolstered its overall financial health. Such successes highlight how strategic energy management can yield tangible benefits.

Another noteworthy case is a beverage manufacturer that opted for compressed air storage technology. This facility managed to enhance its energy efficiency and mitigate peak demand charges significantly. The flexibility provided by stored compressed air allowed the manufacturer to navigate energy price fluctuations adeptly, resulting in reduced operational costs and improved sustainability metrics. These examples underscore that, despite challenges, energy storage systems can create tremendous value in diverse industrial landscapes.

7. FUTURE OF FACTORY ENERGY STORAGE

The trajectory of factory energy storage projects indicates a robust and transformative future. With rapid advancements in technology, increased emphasis on environmentally conscious practices, and growing economic pressures, the importance of these systems is undeniable. Emerging trends suggest that further integration of artificial intelligence (AI) and the Internet of Things (IoT) in energy management systems will significantly enhance energy storage capabilities.

Moreover, continuous research and development into new materials and technologies will expand the potential applications of energy storage. As solutions become more affordable, accessible, and efficient, factories of the future will increasingly incorporate sophisticated energy storage systems. Embracing these advancements is vital for manufacturers striving to remain competitive while addressing sustainability imperatives.

FREQUENTLY ASKED QUESTIONS

WHAT TYPES OF ENERGY STORAGE TECHNOLOGIES ARE AVAILABLE FOR FACTORIES?

Various energy storage technologies cater to industrial needs, each presenting unique benefits. Battery storage systems, predominantly lithium-ion technologies, are prevalent due to their high energy density and rapid response times. However, alternatives like flow batteries, which employ liquid electrolytes, enable longer lifespans and scalability. Compressed air energy storage (CAES) utilizes pressurized air stored in caverns or tanks to generate electricity, providing a different approach to energy storage. Additionally, thermal storage systems capture energy in heat or cold, enabling factories to manage energy demands more efficiently. An understanding of these diverse technologies allows manufacturers to select the most suitable solutions tailored to their specific operational requirements.

HOW DOES ENERGY STORAGE IMPACT OPERATIONAL COSTS FOR FACTORIES?

Implementing energy storage can significantly reduce operational costs for factories. By storing energy during low-demand periods, manufacturers can alleviate peak demand charges associated with high energy usage during peak hours. These costs often represent a substantial component of utility bills, and strategically discharging stored energy during demand spikes can mitigate these expenses. Moreover, energy independence provides additional cost reductions, ensuring that factories are less susceptible to energy price fluctuations and outages. Ultimately, the integration of energy storage fosters a more efficient energy management system, translating directly to lower operational costs and enhanced financial stability for manufacturers.

WHAT ARE THE MAIN CHALLENGES FACING FACTORIES IMPLEMENTING ENERGY STORAGE PROJECTS?

While the advantages of factory energy storage projects are compelling, several challenges may hinder implementation. The initial capital investment required for advanced energy storage technologies can be substantial, posing a barrier for factories with limited resources. Compliance with numerous regulatory standards may also complicate the implementation process. Varying policy landscapes can lead to uncertainties that deter investment in energy storage systems. Furthermore, technological familiarity and operational integration present challenges as factory personnel may require additional training and support to adapt to new systems. Despite these hurdles, proactive planning and strategic partnerships can help manufacturers navigate through complexities, ultimately enhancing industry resilience.

In sum, factory energy storage projects hold significant promise for modern industries, intertwining economic, environmental, and operational advantages. These initiatives encompass innovative technologies designed to optimize energy management and improve sustainability metrics. By embracing energy storage, factories can minimize costs associated with peak energy demand, thereby fortifying their operational resiliency. Despite hurdles, including costs and regulatory concerns, case studies demonstrate that successful energy storage implementations can lead to substantial long-term benefits. Moving forward, collaboration among stakeholders, proactive policy engagement, and continued advancements in technology will likely shape the future landscape of energy storage in industrial settings. Ultimately, the advent of factory energy storage projects resonates with the increasing demand for cleaner, more sustainable energy solutions, translating industry ambitions into tangible outcomes for both manufacturers and the environment. The future is bright for those willing to adapt and innovate within this evolving paradigm.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-is-a-factory-energy-storage-project/