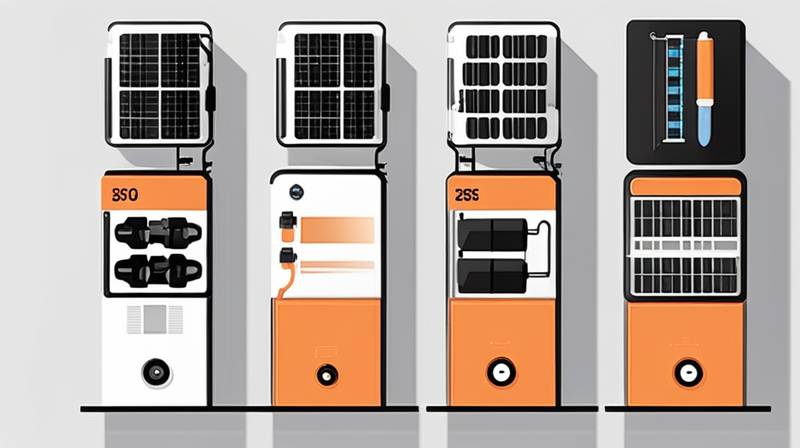

1. The industrial energy storage project encompasses several key components: 1. System design, 2. Implementation strategy, 3. Technology integration, 4. Maintenance and management. The project aims to enhance energy efficiency, provide reliability in power supply, and facilitate the transition to renewable energy sources. This multi-faceted initiative typically integrates various technologies, such as batteries, flywheels, and thermal storage, with the goal of addressing energy demand fluctuations and enabling businesses to optimize energy consumption.

1. SYSTEM DESIGN

A thorough examination of system design is paramount to the success of industrial energy storage initiatives. At this stage, engineers and consultants assess the specific energy requirements of the industrial facility, which may vary according to the type of operation, peak demand periods, and load characteristics. Utilizing advanced modeling software, designers can simulate energy usage patterns, identifying crucial areas where energy storage can alleviate stress on the grid, especially during peak times. Moreover, proper system design will determine the capacity, configuration, and technology selection necessary for effective energy storage.

Integrating energy storage into an existing infrastructure presents various challenges, such as compatibility with current systems and the facility’s layout. Understanding the nuances of power generation, distribution, and consumption in the operation is essential for ensuring that the design provides optimal integration with renewable energy sources, like solar or wind. Additionally, the selection of appropriate materials, components, and technologies must comply with regional regulations and standards to guarantee reliability and safety. Thus, the system design phase is fundamental to ensure that the project meets both operational and regulatory requirements.

2. IMPLEMENTATION STRATEGY

The implementation strategy emerges as a critical phase in the energy storage project lifecycle, dictating how effectively the system design translates into operational reality. Key considerations during this phase include project timelines, resource allocation, and stakeholder engagement. Closing the gap between theoretical model designs and practical application requires meticulous planning and coordination among various stakeholders, including engineers, contractors, suppliers, and regulatory bodies. Each participant must understand their roles and responsibilities to streamline the installation process, ensuring minimal disruption to existing operations.

Moreover, procurement of equipment and technologies must be meticulously curated to avoid delays and cost overruns. A successful implementation strategy encompasses everything from supply chain management to logistical planning to facilitate the seamless delivery and installation of components. Among these are batteries, inverters, and control systems, all of which must be aligned with the project’s timelines and budgets. Effective communication among all parties involved enhances collaboration and helps preemptively address any potential challenges that may arise during installation.

3. TECHNOLOGY INTEGRATION

In this age of rapid technological advancement, technology integration is a vital component of industrial energy storage projects. This aspect pertains to incorporating diverse energy technologies—ranging from traditional battery systems to cutting-edge alternatives like flywheel and pumped hydro systems. Each technology brings unique capabilities and limitations, necessitating a tailored approach that aligns with the specific operational needs of the facility and its energy consumption patterns.

An essential element of technology integration involves ensuring compatibility between different energy systems. For instance, the synchronous operation of battery storage and renewable energy sources, such as solar and wind, requires sophisticated control systems to manage energy flows efficiently. Additionally, the integration of Internet of Things (IoT) devices can revolutionize energy management by providing real-time data and analytics, enhancing decision-making processes and predictive maintenance strategies. This capability not only leads to operational efficiencies, but also offers insights that can inform future expansions or upgrades to the energy storage system. Therefore, solid planning in technology integration phases proves invaluable for maximizing the efficacy of deployed systems.

4. MAINTENANCE AND MANAGEMENT

The maintenance and management of an industrial energy storage system are essential for ensuring long-term performance and reliability. Regular upkeep is vital not only to preserve the functionality of the system but also to minimize downtime, which can incur substantial costs for industrial operations. Scheduled inspections, monitoring of system performance metrics, and proactive maintenance protocols are key aspects of a sound management strategy.

Furthermore, utilizing predictive maintenance tools powered by machine learning and data analytics can help identify potential failures before they occur, thus allowing for timely interventions. By adopting this data-driven approach, companies can optimize their maintenance schedules, reduce the costs associated with unexpected repairs, and extend the lifespan of the energy storage infrastructure. The effective management of energy storage systems is also critical in navigating fluctuations in energy prices and demand, enabling industrial facilities to capitalize on peak shaving techniques and better manage their energy costs. Thus, implementing robust maintenance and management strategies is integral to the sustained success of energy storage projects.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE BENEFITS OF INDUSTRIAL ENERGY STORAGE?

Energy storage systems offer a myriad of benefits to industrial operations. These systems enable facilities to enhance their energy resilience, ensuring a reliable power supply even during outages or grid flares. Moreover, they can facilitate participation in demand response programs, enabling companies to sell stored energy back to the grid during high-demand periods, thus generating additional revenue. The integration of energy storage also significantly contributes to the sustainability objectives of enterprises by allowing for smoothing the incorporation of renewable energy sources. This enhances energy efficiency and reduces reliance on fossil fuels, positively impacting the company’s carbon footprint.

Energy storage additionally allows industries to capitalize on price variations in electricity markets, purchasing power during off-peak times when rates are lower. This dynamic usage can lead to substantial cost savings over time. Furthermore, storage solutions can enhance the stability and reliability of operations by providing a buffer against unforeseen energy surges or drops. This adaptability not only ensures smoother operations but also reinforces the industrial facility’s ability to meet regulatory requirements concerning emissions and sustainability. Implementing an energy storage solution becomes a strategic move that can lead to enhanced profitability and sustainable growth.

HOW DOES ENERGY STORAGE IMPACT SUSTAINABILITY GOALS?

The role of energy storage in meeting sustainability objectives has gained significant attention across various industries. At its core, energy storage systems provide the necessary capabilities for assimilating renewable energy sources into traditional energy grids. By effectively storing excess energy generated from solar or wind, industrial facilities can substantially reduce their greenhouse gas emissions. This capacity allows businesses to move towards a decarbonized model of energy consumption, which is increasingly aligned with global initiatives to combat climate change.

Moreover, the use of energy storage can support the transition to a more circular economy by enabling greater energy efficiency and waste reduction. By leveraging these systems, industries can implement flexible energy management approaches that minimize resource use and optimize processes. Additionally, many regulatory frameworks now incentivize the adoption of cleaner technologies and energy storage systems, creating a conducive environment for companies aiming to meet specific sustainability targets. Thus, energy storage proves to be an essential asset that propels industries toward a more sustainable future, ultimately contributing to corporate social responsibility initiatives and enhancing brand value among eco-conscious consumers.

WHAT TECHNOLOGIES ARE COMMONLY USED IN INDUSTRIAL ENERGY STORAGE PROJECTS?

Several technologies serve as cornerstones in the landscape of industrial energy storage, each characterized by unique capabilities and benefits. Among the most prevalent are lithium-ion batteries, recognized for their high energy density and efficiency. These batteries offer quick response times and are suitable for a range of applications, including load shifting and frequency regulation. However, they are often accompanied by concerns regarding their lifecycle and recycling processes, leading industries to investigate alternative technologies.

Pumped hydro storage, another common solution, uses gravitational potential energy to store large amounts of energy by pumping water to elevated reservoirs during low-demand periods. When energy is needed, the water is released to generate electricity. Although it offers substantial capacity and longer discharge durations, geographical limitations and high initial investments can impede its implementation. Other emerging technologies include flow batteries, which utilize liquid electrolytes to store energy, and thermal energy storage systems, where heat is stored in materials to generate power when required. Each of these technologies presents distinct advantages and considerations, necessitating thorough evaluation and selection based on specific operational needs and economic contexts.

The landscape of industrial energy storage projects encompasses a multitude of facets critical to their successful implementation. Delving into the nuances of system design, effective management strategies, and comprehensive technology integration provides a holistic understanding of how these initiatives come together to serve industrial operations. These projects not only enhance energy efficiency and reliability within the facilities but also align with broader sustainability objectives that are increasingly becoming paramount in today’s business landscape.

Through advancements in technology and strategic planning, industries can optimize their energy consumption patterns while harnessing renewable resources, ultimately transforming operational practices for the better. Furthermore, maintenance and management processes are vital to sustaining these systems, ensuring they deliver consistent benefits over their lifespan. This multifaceted approach positions energy storage as a pivotal industry trend, thus making it an integral component of modern energy management strategies.

In summary, the successful execution of industrial energy storage projects hinges on careful planning and consideration of various elements—from initial system design to long-term operational strategies. As industries continue to face growing energy demands and escalating concerns regarding sustainability, harnessing the potential of energy storage solutions will emerge as a critical pathway for achieving operational excellence while adhering to societal and environmental responsibilities. Therefore, embracing these technologies can offer transformative opportunities for industrial players seeking to thrive in a rapidly evolving energy landscape.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-does-the-industrial-energy-storage-project-include/