What does the factory energy storage project include?

1, The factory energy storage project encompasses various components, primarily focusing on energy capture, storage, and management systems, 2, It integrates renewable energy sources such as solar and wind, 3, Investment in advanced battery technologies for efficiency, 4, Implementation of smart grid technologies for optimized energy distribution, 5, Comprehensive monitoring and maintenance strategies for operational efficiency, 6, Training and development programs for staff.

COMPONENTS OF ENERGY CAPTURE

The foundation of any factory energy storage endeavor begins with energy capture mechanisms that collect renewable energy. This is primarily achieved through the installation of solar photovoltaic (PV) panels and wind turbines situated strategically on-site. The effectiveness of solar panels, for instance, relies on optimal positioning and angle adjustments to maximize sunlight exposure throughout the day. Wind turbines, on the other hand, must be sited to harness natural wind currents efficiently.

The synergy between solar and wind energy captures offers a robust renewable energy tapestry, thereby ensuring a continuous energy supply, especially during peak operational times. This dual approach not only maximizes energy production but also mitigates fluctuations inherent in relying on a single energy source. Ultimately, a reliable capture system lays the groundwork for the entire storage architecture since ample energy reserves dictate the project’s overall success.

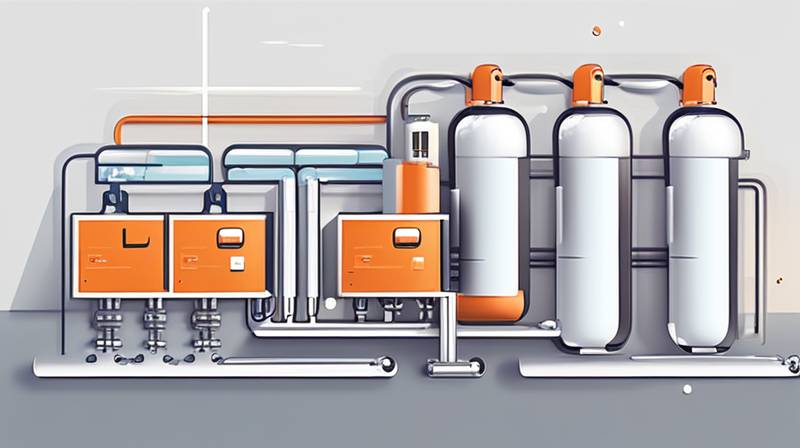

ENERGY STORAGE SYSTEMS

Once energy is harnessed, the next pivotal step is energy storage, which directly facilitates the smooth operation of industrial facilities. Battery storage technologies, particularly lithium-ion systems, have emerged as market leaders due to their efficiency and capacity. These batteries allow for energy retention during periods of low generation, providing stability and balancing energy demand and supply.

Alternative storage systems, such as pumped hydro or compressed air energy storage (CAES), are also considered, albeit with varying applicability depending on location and environmental factors. For instance, pumped hydro necessitates suitable geographic formations, while CAES often requires extensive infrastructural development. The chosen storage solution must align with the factory’s energy utilization patterns and long-term sustainability goals, streamlining operations and enhancing resilience against energy shortages.

SMART GRID INTEGRATION

An essential modern component of factory energy storage projects includes the integration of smart grid technologies. These advanced systems facilitate real-time communication between energy producers, storage units, and consumers. Utilizing sensors and advanced software, smart grids optimize energy distribution according to peak demand, minimizing waste and energizing storage systems when energy prices are low.

The proactive management capabilities intrinsic to smart grids are instrumental in establishing resilience against energy price volatility and enhancing operational efficiency. In tandem with energy management systems (EMS), factories can leverage data analytics to inform better decision-making regarding energy consumption, storage, and procurement strategies. The transformative effect of these technologies shapes a future-proof energy landscape, driving industries towards sustainability and heightened performance.

MONITORING AND MAINTENANCE STRATEGIES

Effective monitoring and maintenance strategies play a crucial role in ensuring the longevity and efficiency of energy storage systems. Routine assessments involve analyzing system performance metrics and environmental conditions that could impact operational efficacy. Implementing preventive maintenance protocols can identify potential issues before they escalate, thereby minimizing downtime and operational disruptions.

Technological advancements allow for sophisticated monitoring capabilities, such as data logging and predictive analytics. These tools provide invaluable insights, enabling facility managers to optimize system performance continuously. Furthermore, comprehensive training programs for technical staff ensure that personnel are well-versed in overseeing these systems, fostering a culture of proactivity around energy management and sustainability.

STAFF TRAINING AND DEVELOPMENT

The human element in a factory energy storage initiative should not be overlooked, as staff training and development substantially influence project success. Employees must be equipped with the necessary knowledge and skills to operate, maintain, and troubleshoot advanced energy systems. This includes understanding the intricacies of battery technologies, energy capture mechanisms, and smart grid operations.

Moreover, continuous education fosters a sense of ownership and accountability among team members, encouraging innovative practices and problem-solving. Investing in training programs creates an adaptive workforce that is capable of both immediate operational challenges and future advancements in energy storage technology. As energy solutions evolve, so too must the proficiency of those managing these critical infrastructures.

ECONOMIC CONSIDERATIONS

Understanding the economic implications associated with factory energy storage projects is paramount. Initial capital outlays can be considerable, necessitating thorough financial analysis and potential sourcing of funding and incentives. It is crucial to evaluate long-term savings resulting from reduced energy costs against these upfront investments to develop a compelling business case.

Additionally, potential economic benefits extend beyond immediate operational cost savings. Improved energy independence can position factories favorably against market fluctuations and reduce vulnerability to energy price hikes. Moreover, energy storage solutions can lead to enhanced sustainability credentials, attracting environmentally conscious consumers and investors who prioritize corporate responsibility.

REGULATORY FRAMEWORK

The development of factory energy storage projects must also consider the regulatory landscape governing energy usage and storage. Compliance with local, regional, and national regulations is critical to avoid financial penalties and ensure the project’s long-term viability. Understanding government policies that support renewable energy and storage technologies can also unlock funding opportunities and tax incentives.

Navigating regulatory complexities often entails engaging with industry bodies and stakeholders to align project objectives with legislative frameworks. Successful mapping of these regulations can accelerate project approval times and facilitate smoother integration of energy storage solutions into existing industrial infrastructures.

ENVIRONMENTAL IMPACT

The environmental implications of factory energy storage projects are noteworthy, as such initiatives are intrinsically linked to sustainability. By harnessing renewable energy sources and optimizing energy consumption, factories can significantly reduce their carbon footprints. Energy storage systems play a vital role in enabling smoother transitions towards greener operations, ultimately contributing to climate change mitigation efforts.

Environmental assessments should, therefore, accompany project planning to evaluate potential ecological impacts and identify measures to minimize disruption. Stakeholder engagement is essential in addressing community concerns and mobilizing support for the initiative, which can enhance the social license to operate.

FREQUENTLY ASKED QUESTIONS

WHAT TYPES OF ENERGY STORAGE TECHNOLOGIES ARE AVAILABLE?

Numerous energy storage technologies exist, each designed to suit varying needs and capacities. Predominantly, lithium-ion batteries are widely adopted due to their high energy density and efficiency. These batteries provide rapid response capabilities, making them ideal for applications requiring immediate energy dispatch.

In addition, alternatives such as flow batteries offer longer-duration storage options, suitable for more extensive, grid-level applications. Pumped hydro storage remains a proven method for large-scale energy storage, designed to facilitate grid stability and energy redistribution. Compressed air energy storage (CAES) also garners attention but requires specific geological formations and extensive infrastructure.

Evaluating these technologies involves considering factors like costs, scalability, availability of resources, and environmental impact, ultimately guiding the decision for the most appropriate solution for a given facility.

HOW DOES ENERGY STORAGE IMPACT OPERATIONAL COSTS?

Investing in energy storage can markedly influence operational costs through various mechanisms. By capturing and storing excess energy produced during low-demand periods, factories can leverage this energy during peak times when electricity prices typically surge. This results in significant savings on energy expenditures over time.

Further, energy storage systems offer the ability to engage in demand response programs, where facilities reduce consumption or shift usage according to grid requirements. The financial incentives from these programs can contribute to lowering overall operational costs significantly. Ultimately, integrating energy storage fosters a more responsive and efficient manufacturing setting where costs can be optimized.

HOW DO GOVERNMENT REGULATIONS AFFECT ENERGY STORAGE PROJECTS?

Government regulations play a crucial role in shaping the landscape for energy storage projects. Compliance with existing laws overseeing energy production, storage, and distribution is essential for project implementation. Moreover, many jurisdictions are currently establishing supportive frameworks aimed at promoting renewable energy initiatives.

These regulatory incentives often include tax credits, grants, and funding opportunities, which can substantially offset initial investments in energy storage technologies. Conversely, non-compliance with regulations can lead to penalties, hampering project success. Therefore, engaging with regulatory bodies to understand and navigate compliance requirements effectively is paramount for any energy storage initiative.

The significance of factory energy storage projects manifests not only in energy management effectiveness but also in fostering sustainable industrial practices. These initiatives encompass multifaceted components, including energy capture, storage technologies, grid integration, and human resource development, reflecting a comprehensive approach to energy efficiency. Moreover, economic considerations, regulatory compliance, and environmental impacts empower organizations to contribute positively to energy landscapes. By embracing innovative solutions and strategies, factories can navigate the dynamic energy market while enhancing operational performance, fostering resilience against fluctuations, and committing to eco-friendly advancements. As industries continue to navigate an increasingly sustainability-driven world, integrating robust energy storage solutions will be vital for navigating future challenges.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-does-the-factory-energy-storage-project-include/