Air-cooled energy storage batteries encompass a variety of components and systems that facilitate the effective storage and management of energy, primarily focusing on thermal regulation through air cooling. 1. These systems primarily include specialized battery types such as lithium-ion and lead-acid batteries, which are designed for efficiency and durability. 2. Additionally, significant components are thermal management systems that utilize air circulation to dissipate heat. 3. Monitoring and control systems for performance optimization are also integrated into these solutions, ensuring that the batteries work efficiently and safely. 4. Lastly, safety equipment and structures form integral parts of air-cooled energy storage units, aimed at preventing overheating and fostering reliability.

Among these aspects, the design and functionality of thermal management systems deserve particular attention, as they play a crucial role in extending battery life and enhancing overall performance. By actively maintaining optimal operating temperatures, air-cooled systems help mitigate risks associated with heat buildup and contribute to more effective energy storage solutions.

1. INTRODUCTION TO AIR-COOLED ENERGY STORAGE BATTERIES

Air-cooled energy storage batteries have emerged as significant technological advancements in the field of renewable energy management. These systems provide solutions for balancing energy supply and demand, especially in contexts where intermittent renewable resources like solar and wind energy are prevalent. The introduction of air-cooled technology reflects a conscious effort to leverage natural ventilation, which promotes efficiency and reduces reliance on artificial cooling systems.

The core principle behind air-cooled energy storage revolves around the efficient management of thermal conditions within the battery framework. By utilizing ambient air as a cooling medium, these systems capitalize on a cost-effective and energy-saving approach to regulate internal temperatures. This is especially important as elevated temperatures can adversely affect battery performance, cycle life, and safety margins, underscoring the necessity of adept thermal management.

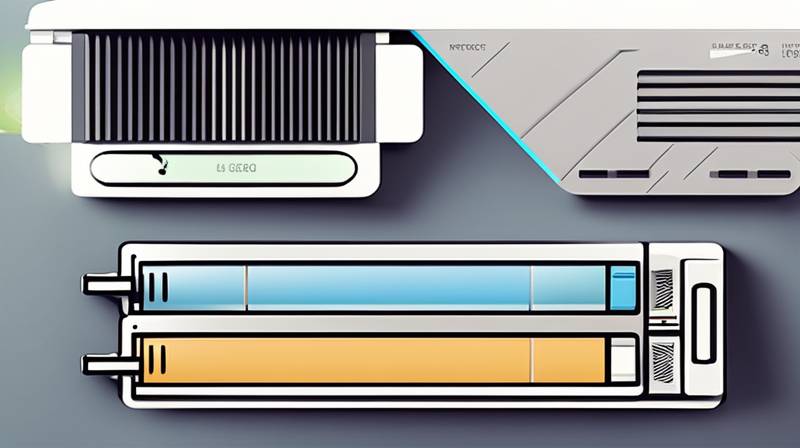

2. COMPONENTS OF AIR-COOLED ENERGY STORAGE BATTERIES

2.1 Battery Types

Diverse battery chemistries are utilized in air-cooled energy storage systems, with lithium-ion and lead-acid being the most prevalent. Lithium-ion batteries stand out due to their high energy density, lightweight properties, and lower self-discharge rates, making them highly suitable for a variety of applications, including electric vehicles and renewable energy integration. These batteries have the ability to deliver high currents, while their modular nature allows for scalable installations, catering to both small and large energy requirements.

Conversely, lead-acid batteries, recognized for their robustness and cost-effectiveness, have garnered extensive use in stationary energy storage applications. Although they possess lower energy densities compared to their lithium-ion counterparts, they offer reliable performance in cyclical charge/discharge scenarios. Recent innovations have also given rise to advanced lead-acid variants, such as absorbed glass mat (AGM) and gel batteries, which enhance durability and performance while remaining cost-efficient.

2.2 Thermal Management Systems

Critical to the performance of air-cooled energy storage batteries are thermal management systems that efficiently regulate temperatures through the circulation of air. The design of these systems often includes fans or blowers that facilitate the movement of air across the battery cells, drawing away excess heat generated during operation. This cooling mechanism is essential for maintaining battery efficiency, as high temperatures can accelerate chemical reactions, leading to diminished battery life and an increased risk of failure.

The efficiency of thermal management systems can be further enhanced through the use of materials with high thermal conductivity. These materials allow for rapid heat dissipation and prevent hotspots from forming within the battery bank. Moreover, intelligent control algorithms can be employed to predict temperature fluctuations and adjust cooling efforts dynamically, thereby optimizing energy use and safeguarding battery performance from potential thermal incidents.

3. MONITORING AND CONTROL SYSTEMS

3.1 Importance of Monitoring Systems

Monitoring and control systems represent a pivotal aspect of air-cooled energy storage batteries, enabling real-time tracking of performance metrics and health indicators. These systems typically consist of sensors and data acquisition technologies that provide insights into temperature, state of charge (SOC), and overall battery health. The significance of these monitoring features cannot be overstated, as they serve to preemptively identify potential issues and facilitate timely interventions, thereby averting catastrophic failures.

The integration of smart monitoring systems also supports remote access capabilities, allowing operators to manage and maintain battery systems off-site. Data analytics further enhance this process by predicting maintenance needs based on usage patterns and environmental conditions. Consequently, this digital transformation in energy storage not only elevates operational efficacy but also fosters safer working environments.

3.2 Control Algorithms and Their Applications

Advanced control algorithms play a critical role in optimizing the performance of air-cooled energy storage systems. These algorithms operate on principles of battery management, ensuring that charging and discharging processes are conducted under optimal conditions. By adjusting operational parameters such as charge rates and thermal management strategies, these algorithms significantly extend battery lifespan and improve energy conversion efficiency.

The implementation of machine learning techniques within control systems allows for adaptive learning from historical data, resulting in optimized operational strategies tailored to specific use-case scenarios. This not only maximizes energy utilization but also enhances the predictability of energy flows, providing a robust framework for integrating air-cooled energy storage systems into larger grid architectures.

4. SAFETY FEATURES AND STRUCTURAL INTEGRITY

4.1 Safety Equipment

Ensuring safety in air-cooled energy storage battery installations is paramount, particularly given the inherent risks associated with large-scale energy storage systems. Safety equipment such as thermal sensors, fuses, and protective relays form a critical part of battery installations. These components detect and mitigate potential hazards like overheating, overcharging, and short circuits, which could otherwise lead to severe incidents.

Moreover, many manufacturers implement built-in safeguards that trigger alarms and system shutdowns when predefined thresholds are crossed. This proactive approach to safety management protects both personnel and the integrity of the entire energy storage system, solidifying confidence in the reliability and security of air-cooled technology.

4.2 Structural Design Considerations

The structural design of air-cooled energy storage systems must account for several engineering principles to ensure long-term reliability. Incorporating materials that resist corrosion and thermal degradation extends the lifespan of the battery housings and enclosures. Airflow dynamics must also be carefully considered, as they influence the distribution of cooled air and the dissipation of heat across the battery modules.

The layout of the battery banks should allow for unobstructed airflow, optimizing the cooling effect while preventing thermal clustering among packed cells. Furthermore, structural reinforcements are essential to withstand external forces and environmental factors, ensuring stability during operation and maintenance activities.

5. ECONOMIC IMPLICATIONS AND INSTALLATION CONSIDERATIONS

5.1 Cost Factors in Installation

Economic considerations play a vital role in the adoption of air-cooled energy storage batteries. While initial investment costs can be substantial, the long-term return on investment (ROI) may justify the expenditure. Factors such as operating costs, intensity of energy usage, and the longevity of the battery system directly influence the overall economics of air-cooled installations.

Key cost drivers include the price of battery technology, necessary infrastructure, and ongoing maintenance requirements. However, reductions in costs for lithium-ion batteries have made them increasingly accessible, allowing for wider utilization in both residential and commercial markets. Careful engineering and planning can also optimize installation expenses, maximizing the economic viability of investment.

5.2 Long-Term Maintenance and Lifespan

Maintenance regimes are crucial to the longevity and availability of air-cooled energy storage batteries. Establishing schedules for routine inspections and preventive maintenance can significantly extend the operational lifecycle of the system. Proper care and attention to mechanical components, thermal management systems, and monitoring technologies contribute to sustainable performance over the years.

In practice, battery replacement strategies may also need to be integrated into long-term planning. As battery technologies evolve, older systems may require replacement to harness advancements that enhance performance and safety. Thus, understanding replacement cycles and budgetary constraints enables stakeholders to create realistic and actionable maintenance plans.

COMMON INQUIRIES

WHAT ADVANTAGES DOES AIR-COOLED ENERGY STORAGE PROVIDE?

Air-cooled energy storage systems offer several prominent benefits, making them a preferred choice in various energy applications. Their reliance on ambient air for cooling significantly reduces operating costs, as there is no need for extensive refrigeration systems or energy-intensive cooling methods. This eco-friendly aspect aligns with the global push toward sustainable energy solutions.

Moreover, air-cooled designs promise reduced complexity, as they often necessitate less intricate engineering associated with liquid cooling systems. This simplicity not only facilitates installation but also streamlines ongoing maintenance tasks. Additionally, the lower risk of leaks and environmental contamination enhances safety profiles, making them ideal for both commercial and residential settings.

HOW DOES THERMAL MANAGEMENT AFFECT BATTERY PERFORMANCE?

Thermal management serves as a cornerstone for maximizing the efficiency and longevity of air-cooled energy storage batteries. Elevated temperatures can accelerate wear and chemical degradation, fundamentally compromising performance. Effective thermal regulation ensures that batteries operate within safe temperature ranges, which is critical for preserving structural integrity and preventing thermal runaway scenarios.

Moreover, maintaining optimal temperatures improves energy density and charge/discharge cycles, enabling batteries to perform more efficiently. Furthermore, advanced thermal management systems equipped with enhanced sensor technology provide real-time data, allowing for adaptive adjustments based on usage, ambient conditions, and operational requirements.

WHAT IS THE AVERAGE LIFESPAN OF AIR-COOLED ENERGY STORAGE BATTERIES?

The average lifespan of air-cooled energy storage batteries is contingent upon various factors, including battery chemistry, usage patterns, and thermal management. Typically, lithium-ion batteries boast lifespans ranging from 10 to 15 years under optimal conditions, while lead-acid batteries may last 5 to 10 years. Efficient thermal regulation critically influences these lifespans, as consistently high operating temperatures can degrade battery health significantly over time.

Regular maintenance and appropriate operational practices also play roles in determining longevity. Implementing proactive measures, such as monitoring health metrics and adhering to recommended charging protocols, extends the useful life of these energy storage systems. With advancements in technology and design, ongoing innovations bode well for the future durability of air-cooled energy storage solutions.

In summary, air-cooled energy storage batteries comprise various interconnected elements that enhance energy management while addressing critical performance concerns. Their reliance on sophisticated thermal management systems, coupled with effective monitoring controls, underscores the importance of such technologies in today’s energy landscape. Investing in these systems promises economic efficiencies and sustainability, aligning with global goals for resource optimization. The foundational components, safety features, and long-term economic viability indicate a growing market potential, reflecting the broader adoption of renewable energy solutions across multiple sectors. As technology continues to advance, there remains substantial optimism about the future of air-cooled energy storage systems and their role in facilitating a cleaner, more reliable energy future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-does-air-cooled-energy-storage-battery-include/