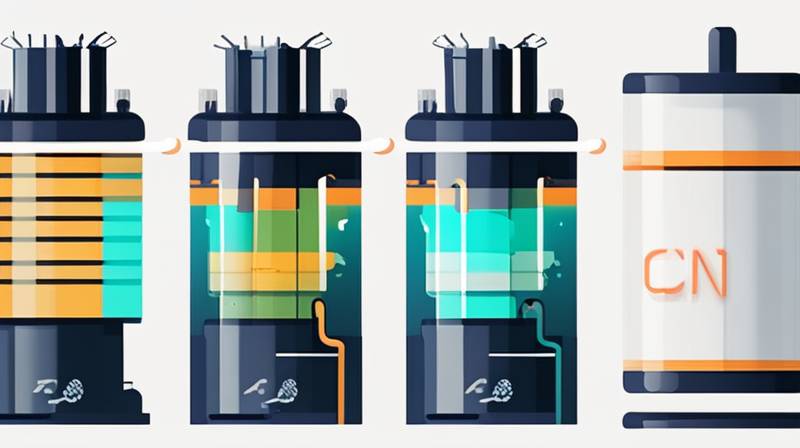

Capacitors utilized for energy storage and filtering predominantly include 1. Electrolytic capacitors, 2. Film capacitors, 3. Tantalum capacitors, and 4. Ceramic capacitors. Electrolytic capacitors are distinguished by their high capacitance values and are extensively used in DC applications to smooth voltage fluctuations. Their construction involves a dielectric layer formed by an oxide, which allows them to store significant amounts of charge. The choice of a capacitor often depends on its ESR (Equivalent Series Resistance) and the application requirements. Other types, such as film capacitors and ceramic capacitors, are favored for their stability and lower energy losses. These details emphasize the importance of understanding different capacitor types when considering their roles in energy storage and filtering applications.

1. ENERGY STORAGE CAPACITORS: AN OVERVIEW

In various electrical engineering applications, capacitors serve pivotal roles, especially concerning energy storage and filtering. Capacitors store electric energy and release it when needed, making them essential components in power supply circuits and energy conditioning systems. Their capacitance values and frequency characteristics significantly influence their effectiveness.

Electrolytic capacitors have a unique composition that allows them to retain large amounts of energy. They are often polarized, meaning they have a positive and negative terminal, thus necessitating careful installation to avoid damage. These components exhibit high capacitance typically ranging from microfarads to farads. Due to this characteristic, they are widely employed in power supply filtering applications to smooth output voltage levels and mitigate ripple in power circuits.

2. FILM CAPACITORS: THE STABILITY SOLUTION

When discussing energy storage and filtering, film capacitors emerge as a reliable alternative to electrolytics. These capacitors use thin plastic films as dielectrics, and their construction offers stability over variable temperature ranges and voltages. Film capacitors provide minimal losses, making them suitable for applications where efficiency is paramount.

The benefits extend beyond performance; they also include excellent self-healing properties, which allow damaged dielectric materials to recover seamlessly from small breakdowns. Their high insulation resistance and low ESR allow them to maintain integrity in high-frequency applications, resulting in dependable filtering.

These capacitors, characterized by their robustness, find their place in power electronics, audio systems, and any application where signal integrity is crucial. The versatility of film capacitors makes them a favored choice across diverse fields, from industrial machines to consumer electronics.

3. TANTALUM CAPACITORS: A PREMIUM CHOICE

Tantalum capacitors are recognized for their compactness and reliability, making them ideal for various energy storage applications. Composed of tantalum metal and an insulating oxide, they offer high capacitance in relatively small sizes. This unique construction provides a robust solution for designers seeking to save space while ensuring efficient energy storage and filtering.

One key characteristic of tantalum capacitors is their ESR, usually lower than that of comparable electrolytic capacitor types. This quality enables them to perform exceedingly well in high-frequency applications, such as in telecommunications and consumer electronics. The stable performance across a wide temperature range makes tantalum capacitors a premium choice, particularly in critical applications where failure is not an option.

However, it is crucial to note that tantalum capacitors are polarized, similar to electrolytics, which means they must be connected in the correct orientation. When used properly, they demonstrate outstanding reliability in various configurations, which can lead to improved performance in energy storage and filtering tasks.

4. CERAMIC CAPACITORS: VERSATILITY AND RELIABILITY

Ceramic capacitors have gained popularity due to their versatility and affordability. These components are composed of ceramic materials and are universally used in filtering applications, where stability and temperature resilience are paramount. The absence of polarity distinguishes ceramic capacitors, allowing for flexible circuit implementations.

Their capacitance typically ranges from picofarads to microfarads, suitable for high-frequency filtering in RF applications. The capacitor’s ability to withstand high voltage levels without failure makes it an attractive choice for power supply applications. Ceramic capacitors exhibit minimal losses, enabling excellent performance in various electronic devices, from smartphones to medical equipment.

Despite their many advantages, ceramic capacitors can experience capacitance variance due to temperature changes and applied voltage. Designers must take into account these characteristics when selecting capacitors for filtering applications. Nonetheless, their affordability, efficiency, and wide applicability ensure that ceramic capacitors will remain integral to energy storage and filtering tasks in various devices and applications.

FAQs

WHAT FACTORS INFLUENCE CAPACITOR CHOICE?

Selecting the appropriate capacitor type for energy storage and filtering hinges on various considerations. The first factor is capacitance value, which dictates how much charge a capacitor can store. Higher capacitance often means better energy storage capacity. The operating voltage also plays a critical role since exceeding this threshold can lead to capacitor failure.

Another vital aspect is Equivalent Series Resistance (ESR), which affects the capacitor’s performance, particularly in filtering applications. A lower ESR usually implies better efficiency and reduced heat generation. Additionally, environmental conditions, including temperature range and potential exposure to moisture, influence the choice of capacitor materials. For instance, tantalum capacitors are often chosen for their reliability in critical applications despite higher costs. Thus, when selecting capacitors for energy storage filtering, one must evaluate capacitance, voltage rating, ESR, and environmental factors comprehensively.

HOW DO CAPACITORS IMPACT POWER SUPPLY CIRCUITS?

In power supply circuits, capacitors perform essential functions that directly affect the system’s efficiency and stability. By storing electric energy, capacitors can quickly deliver power during transient conditions, aiding in voltage regulation. This characteristic is crucial for maintaining consistent output levels, particularly in situations where load demands can fluctuate significantly.

Additionally, capacitors play a pivotal role in filtering applications by removing unwanted frequencies from voltage signals. They help smooth the voltage waveform, diminishing ripple and noise introduced by switching or varying load conditions. The choice of capacitor type significantly impacts these functions; for instance, electrolytic capacitors are commonly employed to filter low-frequency ripples, while ceramic capacitors are often suited for high-frequency filtering applications. Ensuring appropriate capacitors in power supply circuits enhances overall performance, stability, and reliability.

WHAT ARE THE LIMITATIONS OF COMMON CAPACITOR TYPES?

While capacitors are invaluable in energy storage and filtering, each type exhibits specific limitations that users must consider. Electrolytic capacitors, for instance, are subject to aging and potential leakage over time, particularly in high-temperature environments. They also exhibit polar characteristics, necessitating careful installation to prevent failure due to incorrect orientation.

Film capacitors, while stable, can be bulkier than their electrolytic counterparts and may present higher costs, which can be a drawback for budget-conscious projects. Tantalum capacitors, despite their reliability, are subject to catastrophic failure if they are over-voltage, posing risks in sensitive applications if misused.

In contrast, ceramic capacitors, while versatile, exhibit capacitance variation under different environmental conditions, which might lead to inconsistent performance in filtering applications. Understanding these limitations enables engineers and designers to make informed decisions when incorporating capacitors into their designs.

Strengthening the essence of capacitor use is vital to harnessing their full potential. Each type has its unique strengths that cater to different needs and applications. When engaging in energy storage and filtering duties, a comprehensive understanding of these critical components ensures optimal performance and reliability in electronic systems. Hence, choosing the correct capacitor type goes beyond simple installation; it requires a thorough evaluative process that considers all factors and potential obstacles.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-capacitors-are-used-for-energy-storage-filtering/