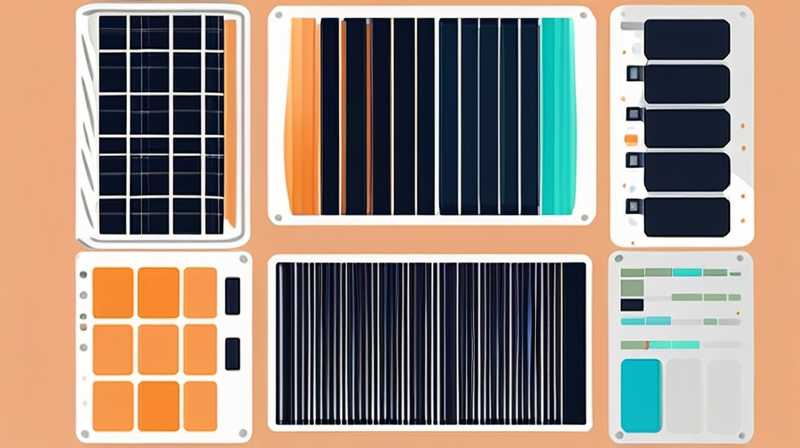

1. SOLAR SILICON CELL TYPES ARE CRUCIAL FOR UNDERSTANDING THE SOLAR INDUSTRY, 2. MONOCRYSTALLINE CELLS OFFER HIGH EFFICIENCY AND LONGEVITY, 3. POLYCRYSTALLINE CELLS PROVIDE A BALANCED OPTION BETWEEN COST AND PERFORMANCE, 4. THIN-FILM CELLS UTILIZE A DIFFERENT TECHNOLOGY, PROMOTING FLEXIBILITY AND LIGHTWEIGHT INSTALLATIONS.

Monocrystalline Silicon Cells stand as the most efficient type of solar cells, primarily due to their highly organized crystal structure. These cells originate from single crystal silicon, offering a higher purity level. This purity translates into improved electronic properties, enabling superior energy conversion efficiency, often exceeding 20%. The manufacturing process is more complex and costly, but the end result is a product that not only lasts longer but often performs better in low-light conditions. This remarkable efficiency makes monocrystalline panels an excellent choice for installations where space is limited and maximum output is necessary.

Polycrystalline Silicon Cells are another popular type, recognized for their more affordable production process compared to monocrystalline counterparts. These cells consist of multiple silicon crystals melted together, resulting in a mosaic-like structure. While their efficiency generally ranges between 15% to 20%, they offer a balanced option for consumers who prioritize cost-effectiveness without dramatically sacrificing performance. The manufacturing process, though simpler, does result in a lower energy yield, yet updates in technology continue to improve their efficiency and lower costs, making them accessible for various applications.

Thin-Film Solar Cells diverge from traditional silicon-based technologies by utilizing a thin layer of photovoltaic material on a substrate. This category includes three main types: cadmium telluride, amorphous silicon, and copper indium gallium selenide. These cells are particularly lightweight and flexible, which allows for applications in unconventional settings, such as on curved surfaces or integrating with building materials. Their production typically results in lower energy costs but at the expense of efficiency, often falling below 12%. Nonetheless, advancements in thin-film technology continue to enhance performance metrics, offering new potential for widespread adaptability in various environmental conditions.

1. UNDERSTANDING MONOCRYSTALLINE SILICON CELLS

Monocrystalline silicon cells represent the pinnacle of solar technology in terms of efficiency and longevity. Their structure consists of a single crystal of silicon, which results in fewer grain boundaries, thus facilitating unimpeded movement of electrons when exposed to sunlight. This feature significantly enhances energy conversion rates compared to other types. Efficiency ratings often exceed 20%, making them ideal for applications where space is at a premium.

The production process for monocrystalline cells involves the Czochralski method or the float-zone method, both of which require advanced technical expertise and sophisticated facilities. After the silicon is purified, it is melted and formed into cylindrical ingots, later sliced into thin wafers. This meticulous process ensures the high purity levels necessary for optimal performance. Due to their intricate manufacturing, monocrystalline panels typically come with a higher price tag. However, the initial investment pays dividends in the form of lower electricity bills and greater energy yield over the lifetime of the product.

2. POLYCRYSTALLINE SILICON CELLS

Polycrystalline silicon cells offer a more economically viable alternative while still providing respectable performance. As the name suggests, these cells comprise multiple silicon crystals, leading to a more varied structure, which impacts their efficiency. While they usually perform at efficiencies between 15% and 20%, their lower cost of production has made them widely popular among residential users and larger commercial installations.

The manufacturing of polycrystalline cells begins with the melting of raw silicon, which is then cooled and crystallized into blocks before being sliced into wafers. This process tends to be less energy-intensive and more cost-effective than that of monocrystalline cells. As a result, many manufacturers favor polycrystalline options for mass production. While they do not usually match the performance of monocrystalline cells, ongoing innovations continue to enhance their energy output, making them a competitive choice in the renewable energy market.

3. THIN-FILM SOLAR CELLS

Distinguished from their crystalline counterparts, thin-film solar cells utilize a markedly different methodology. By depositing a thin layer of photovoltaic material onto a substrate, this technology achieves a lightweight and flexible form factor, which opens avenues for unique applications, including building-integrated photovoltaics (BIPV) and portable devices. The flexibility of thin-film cells allows for integration into diverse surfaces and environments, catering to a wide range of consumer needs and preferences.

Three primary types of thin-film cells are notable for their distinct materials: cadmium telluride (CdTe), amorphous silicon (a-Si), and copper indium gallium selenide (CIGS). While these options generally provide lower efficiency rates—often around 10% to 12%—they excel in low-light conditions, potentially offering advantages in environments with diffuse sunlight. The reduced material costs associated with thin-film technologies often translate to affordable solar solutions, although these cells may require larger installation areas to compensate for their lower efficiency levels.

4. THE FUTURE OF SOLAR SILICON CELL TECHNOLOGY

The solar industry is in a dynamic state of evolution, with advancements contributing substantially to all types of silicon cells. Research focuses on improving efficiency rates and decreasing production costs. Emerging technologies explore the viability of bifacial solar panels, which capture sunlight on both sides, maximizing energy yield. Additionally, innovations like perovskite solar cells are drawing attention for their potential to outperform traditional silicon technologies.

Environmental factors also play a pivotal role in shaping the future landscape of solar energy. Increased public awareness regarding clean energy solutions propels innovation, resulting in growing investment in solar technologies. Alongside advances in recycling technologies, improvements in the lifecycle management of solar panels ensure better sustainability practices. Consequently, the push for energy transition corroborates a favorable outlook for silicon cell evolution, aiming to bolster both efficiency and environmental consciousness in the coming years.

CREATING ACCESSIBLE SOLAR OPTIONS FOR ALL

Accessibility to solar energy solutions remains an enormous challenge across numerous demographics. While advancing technology continues to lower costs, the disparity in access to renewable energy persists. Community solar projects represent one solution, where multiple households or stakeholders own or share a single solar facility, allowing those without appropriate roofs or means to invest in solar equipment to also benefit from solar energy.

Government programs and initiatives, coupled with private enterprise efforts, strive to promote equitable access to solar technology. Financial incentives, tax breaks, and grants can lower the barriers to entry for underserved populations. Additionally, educational outreach endeavors aim to inform communities about the potential of renewable energy, empowering them to take actionable steps toward adopting solar technologies suited to their needs.

1. WHAT ARE THE MAIN TYPES OF SOLAR SILICON CELLS?

Solar silicon cells primarily fall into three categories: monocrystalline, polycrystalline, and thin-film. Monocrystalline silicon cells are regarded for their high efficiency and are made from a single crystal structure, making them ideal for limited space settings. Polycrystalline cells, composed of multiple crystals, offer a lower production cost while maintaining decent efficiency, making them popular for residential and commercial use. Thin-film cells represent an alternative technology that is lightweight and flexible, allowing for innovative applications but typically come with lower efficiency rates.

2. WHAT ARE THE ADVANTAGES OF MONOCRYSTALLINE SILICON CELLS?

Monocrystalline silicon cells offer several compelling advantages. Their efficiency rates are among the highest in the industry, often over 20%, allowing for greater energy yield from a limited space. This makes them incredibly suitable for urban settings where space is a premium. Their longevity is another benefit—many monocrystalline panels come with warranties lasting 25 years or more. Additionally, they perform better in low-light conditions compared to other cell types, contributing to their overall appeal in diverse climatic environments.

3. HOW DO THIN-FILM SOLAR CELLS DIFFER FROM TRADITIONAL SILICON CELLS?

Thin-film solar cells differ notably from traditional silicon cells in both structure and production. Unlike monocrystalline and polycrystalline cells, which use silicon wafers, thin-film cells are constructed with a thin layer of photovoltaic material deposited on a substrate. This structure allows for greater versatility, as the panels can be lightweight and flexible, which enables integration into various surfaces and shapes. However, thin-film cells generally have lower efficiency rates, approximately 10% to 12%, compared to their crystalline counterparts. The trade-off between flexibility and efficiency dictates their applications in the solar market.

The exploration of solar silicon cell types unveils a multifaceted landscape that reflects advancements in material science and technology. Recognizing the distinctions among these cells—monocrystalline, polycrystalline, and thin-film—enables a nuanced understanding of their respective strengths and weaknesses. Monocrystalline options emerge as leaders in efficiency and longevity, catering to energy-conservative consumers seeking high returns on investment. Polycrystalline alternatives present a cost-effective solution, providing a balance between output and affordability, empowering a broader range of users to participate in renewable energy adoption. On the other hand, thin-film cells bring an entirely different dimension with their flexible applications, appealing to both innovative designers and conventional users alike.

Evolving trends and technologies signal a promising future for solar silicon cells, marked by ongoing enhancements in efficiency, sustainability, and accessibility. By addressing barriers such as cost and structural limitations, the solar industry is charting a path toward equitable access to renewable energy. Collaborations among government entities, nonprofits, and private corporations amplify these efforts, aiming to illuminate diverse socioeconomic landscapes with solar potential. As society progresses toward cleaner energy sources and enhanced sustainability, grasping the intricacies of solar silicon cell technology will serve as a cornerstone in the global transition toward renewable solutions. The coming years are likely to witness even greater advancements, redefining solar energy’s role as an integral component of our energy infrastructure.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-the-types-of-solar-silicon-cells/