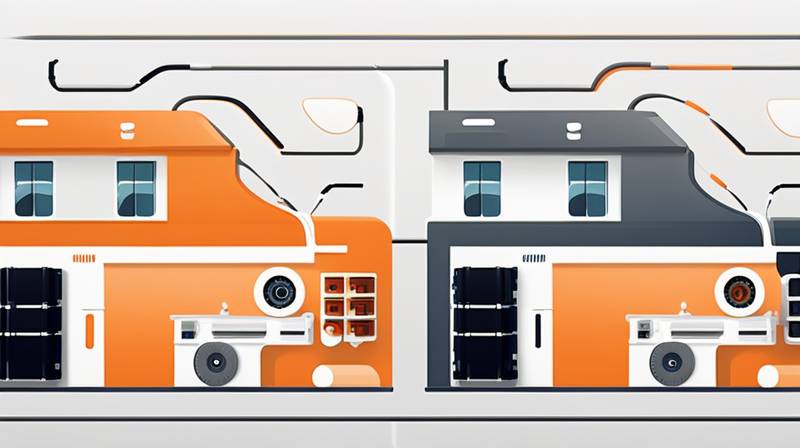

1. The essential components for domestic energy storage vehicles encompass a variety of elements that ensure optimal functionality and efficiency. These include a. Battery units that serve as the primary storage medium, b. Inverters to convert direct current into usable alternating current, c. Thermal management systems for maintaining temperature regulation, d. Control systems that facilitate integration with renewable energy sources. The battery unit is particularly crucial since it determines the total energy capacity and impact the overall performance of the energy storage vehicle. When choosing a battery, factors such as chemistry, lifecycle, energy density, and charge efficiency should be carefully considered as they directly influence storage and discharge capabilities.

1. BATTERY UNITS

The battery unit stands at the forefront of any energy storage vehicle’s operation. Characterized by its capacity to store energy generated from renewable sources, such as solar and wind, the battery serves as the heart of the entire system. Its performance hinges on the type of battery technology employed, and various options are available in the market—from lithium-ion batteries renowned for their efficiency and energy density, to lead-acid varieties, celebrated for their cost-effectiveness but with limitations in terms of lifecycle and weight.

One must also consider the installation configuration. Batteries can be installed in series or parallel arrangements, with each configuration providing unique advantages regarding voltage and current output. This decision is pivotal since it affects the overall efficiency and safety of the system. Safety measures must be integrated into the installation process to prevent overheating, which can lead to battery failure or dangerous scenarios. Regular maintenance and monitoring of the battery health enhance performance longevity, making it imperative for owners to stay informed about potential indicators of degradation.

2. INVERTERS

Inverters play a pivotal role in domestic energy storage vehicles by converting direct current (DC) produced by the battery into alternating current (AC), which is the form of electricity typically consumed by domestic appliances. This conversion is essential for ensuring that the energy stored in the battery can be effectively utilized within a household. There are various inverter types, including string inverters, microinverters, and hybrid inverters, each suited to different applications and system configurations.

Choosing the right inverter is influenced by several factors, such as efficiency ratings, power output, and compatibility with the battery storage system. A significant consideration is the inverter’s capacity to handle peak power loads, which fluctuate based on appliance usage. Inverters also feature monitoring systems that provide real-time data on energy generation, consumption, and storage levels, which is vital for users aiming to optimize energy utilization and reliance on grid electricity. Consistent updates and improvements in inverter technology can lead to enhanced reliability and energy efficiency—key factors in long-term satisfaction and cost savings.

3. THERMAL MANAGEMENT SYSTEMS

The efficiency and lifespan of battery units in energy storage vehicles can be significantly impacted by temperature. Thermal management systems are essential in maintaining optimal operating conditions, preventing overheating, and extending the usable life of battery units. These systems can employ passive or active methods to manage temperature. Passive systems rely on external cooling mechanisms, while active systems leverage fans or water-cooling processes to regulate battery temperature actively.

Effective thermal management directly correlates with performance; when batteries operate within ideal temperature ranges, they show improved charge-discharge cycles and minimized risks of thermal runaway—a condition where the battery overheats uncontrollably. Investors and users must ensure that thermal management systems are integrated into their energy storage setup meticulously. Regular inspections and updates to these systems will enhance their efficiency, ensuring that the vehicle operates with maximum effectiveness over time.

4. CONTROL SYSTEMS

Control systems facilitate the seamless integration of energy storage vehicles with various components within the energy ecosystem, including grid ties and renewable sources. These systems enable real-time monitoring, data collection, and automated decision-making processes regarding when to store, when to use energy, and when to discharge back to the grid. An effective control system can optimize energy consumption patterns, which is particularly advantageous in residential settings with varying energy demands throughout the day.

Modern control systems incorporate advanced software that offers remote access via smartphone applications, allowing owners to monitor energy flow and make adjustments based on their unique usage patterns. Features such as demand response functionalities allow for dynamic interactions with the electricity grid—incentivizing users to consume energy during off-peak hours while providing compensation when energy is discharged back during peak hours. Continuous advancements in control systems play an essential role in enhancing user experience by fostering a straightforward, less cumbersome operation of the entire energy storage vehicle system.

5. POWER MANAGEMENT AND ELECTRICAL CONNECTIONS

Power management and electrical connections are foundational elements that ensure energy flows efficiently between different components of energy storage vehicles. These intricate interconnections handle the transmission of electrical signals between the battery, inverter, generating sources, and the home. With poorly executed connections, the risk of energy loss and system inefficiency rises exponentially — hindering optimal performance.

Installation of specialized cables designed to handle specific current loads is paramount. Furthermore, safety devices such as circuit breakers and fuses must be integrated within the electrical layout to prevent overload situations that can damage components or result in hazardous incidents. Regular inspection and maintenance of these connections contribute to sustainable performance and longevity of the energy storage vehicle.

6. CHARGING STATIONS AND GRID CONNECTIONS

Charging stations designed specifically for energy storage vehicles are crucial components that demand careful consideration. These stations not only provide users the capacity to recharge batteries but also facilitate the intake of energy from the grid or renewable sources. A well-designed charging station with integrated safety features ensures that the charging process is monitored, controlled, and safely executed.

Additionally, grid connectivity provides homeowners significant flexibility, allowing them the potential to earn money through net metering policies, where excess energy produced and stored can be sold back to the grid. Homeowners can benefit from time-of-use rates, capitalizing on lower electricity costs during off-peak hours while accessing stored energy during peak usage times, further optimizing their energy expenditure.

7. MONITORING AND DIAGNOSTIC TOOLS

To maximize the efficiency and effectiveness of energy storage vehicles, monitoring and diagnostic tools are invaluable. These tools help in assessing performance metrics, conducting routine system checks, and identifying potential issues before they escalate into larger problems. Key performance indicators include battery health, cycle count, temperature, and overall energy efficiency.

For users, proactive monitoring allows them to stay ahead of maintenance schedules, ensuring components operate smoothly. Manufacturers increasingly incorporate software that provides predictive insights based on collected data, allowing users to make informed decisions regarding usage patterns and necessary upgrades. This forward-thinking approach results in enhanced longevity of the system and improved user experiences.

8. SAFETY COMPONENTS

In the realm of energy storage, safety components cannot be overlooked. Ensuring that vehicles are equipped with the right safety features is critical to preventing accidents and ensuring user confidence. Devices such as thermal fuses, fire suppression systems, and advanced battery management systems are integrated to monitor and regulate energy flow effectively.

Proper installation protocols and adherence to safety standards create an environment where users can rely on their energy storage systems with peace of mind. Furthermore, educating consumers about safe operation practices and proper maintenance routines contributes significantly to the longevity and integrity of the entire energy storage solution.

FREQUENTLY ASKED QUESTIONS

WHAT TYPES OF BATTERIES ARE COMMONLY USED IN ENERGY STORAGE VEHICLES?

The predominant types of batteries employed in energy storage vehicles include lithium-ion and lead-acid systems. Lithium-ion batteries are preferred mainly due to their high energy density, longer life, and lower self-discharge rates compared to lead-acid counterparts. They are versatile in a variety of installations and come in many variations, such as LFP (lithium iron phosphate) and NMC (nickel manganese cobalt), each catering to specific performance demands and applications. Lead-acid batteries, on the other hand, have been a staple in the industry due to their lower initial costs, though they generally require more maintenance and have shorter lifespans. Proper selection based on cost-effectiveness, charging characteristics, and capacity are imperative for achieving optimal performance in a vehicle.

HOW DO CONTROL SYSTEMS ENHANCE EFFICIENCY IN ENERGY STORAGE VEHICLES?

Control systems improve efficiency in energy storage vehicles significantly by gathering data about energy usage, adjustable depending on current demands. These systems assess the optimal times for energy utilization, storage, or feeding back into the grid. With the aid of advanced algorithms, the system can execute decisions with great precision, ensuring that energy is used in the most efficient manner possible—conserving electricity and minimizing utility costs. Real-time monitoring allows users to adjust their energy consumption patterns dynamically, enabling adjustments based on fluctuations in energy needs and sources.

WHAT ARE THE SAFETY MEASURES FOR ENERGY STORAGE VEHICLES?

Safety measures in energy storage vehicles encompass various essential elements, including thermal management systems, circuit protection devices, and routine maintenance protocols. Regulatory compliance and adherence to safety standards during installation create a safe operational environment. Thermal fuses and battery management systems monitor voltage and temperature to avoid dangerous conditions, thus averting potential failures or hazards. Routine inspections and updates help ensure that everything functions smoothly, promoting user confidence and safeguarding investments in energy storage technology.

The aspects surrounding spare parts and components for domestic energy storage vehicles demonstrate a complex and interconnected network crucial for efficient operation. The battery, serving as the core storage unit, dictates performance effectiveness, while inverters ensure the transformation of stored energy into a usable format for home consumption. Equally important, thermal management systems uphold optimal operating conditions, reinforcing battery longevity, and control systems enable real-time adjustments that maximize energy efficiency. Additionally, power management systems facilitate smooth energy flow between all components, while dedicated charging infrastructures and robust safety features enhance overall user experience and safety. Monitoring tools provide critical diagnostics, allowing proactive management of the system’s performance.

In essence, those seeking to understand or implement energy storage solutions for domestic usage must approach the selection and integration of spare parts with a comprehensive view of all operational dynamics. Careful attention to each component ensures optimum energy management, allows for seamless interaction with renewable sources, and ultimately contributes to a more sustainable energy model. The future of energy storage technology lies in addressing these intricate components collectively, ensuring technological advancements align with consumer needs and safety standards, fostering a shift towards cleaner, more sustainable energy systems. As the industry continues to evolve, keeping abreast of developments in battery technology, system integration, and safety protocols will position users for success within the expanding landscape of energy storage solutions.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-the-spare-parts-for-domestic-energy-storage-vehicles/