The devices employed in energy storage systems are primarily distinguished by their utilization of various pumping mechanisms for fluid transportation. 1. Energy storage pumps serve to facilitate efficient fluid movement, 2. Various types of pumps are integral to different energy storage technologies, 3. The selection of pumps depends significantly on the specific energy storage mechanism deployed, 4. Comprehensive understanding of pump capabilities enhances overall system performance. One noteworthy pump type commonly used is the centrifugal pump, which excels in moving fluids at high flow rates while maintaining efficiency. This type of pump is particularly advantageous in applications such as large-scale pumped hydro storage, where volumes of water are elevated to facilitate energy storage. Other types include positive displacement pumps, which provide precise fluid delivery, making them suitable for systems where performance consistency is paramount. Each pump type aligns with specific energy storage solutions, optimizing the effectiveness of energy capture, retention, and release processes.

1. INTRODUCTION TO ENERGY STORAGE PUMPS

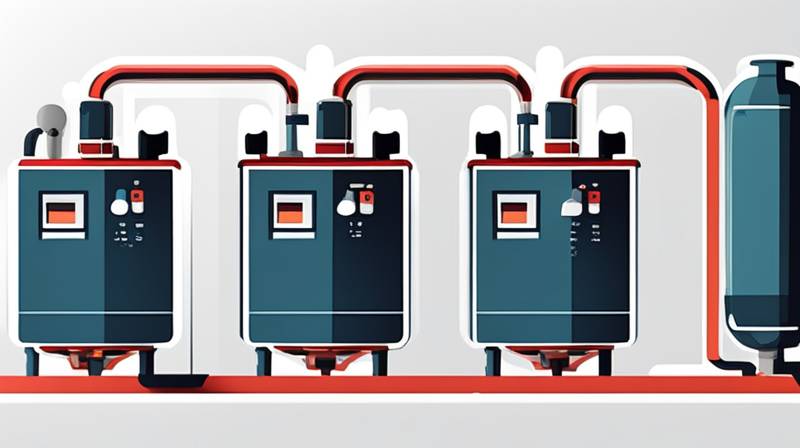

The landscape of energy storage technology has witnessed exceptional advancements in recent years, largely attributed to the critical role that pumps play within these systems. Pumps are indispensable for energy storage equipment, specifically in scenarios where fluid movement is essential for energy transfer and conversion. The two prevalent forms of energy storage systems that utilize pumps include pumped hydroelectric storage and various thermal energy storage systems. Each of these systems employs distinct pumping technologies that cater to the specific demands of their operational mechanics.

In pumped hydroelectric storage, water is cycled between two reservoirs situated at different elevations. The role of pumps in this context is vital, as they allow for the elevation of water during off-peak energy production, storing energy in the form of gravitational potential energy. When energy demand peaks, the stored water is released to generate power through turbines. Alternatively, thermal energy storage systems, which may incorporate heat transfer fluids, also utilize specific pumping technologies to circulate fluids, ensuring energy retention and transfer efficacy remain optimal. By understanding the intricate functionalities of various pump types, stakeholders can optimize their energy storage systems to enhance efficiency and performance.

2. CENTRIFUGAL PUMPS IN ENERGY STORAGE

Centrifugal pumps are among the most commonly utilized pumping technologies in various energy storage systems, particularly in pumped hydroelectric systems. These pumps operate on the principle of converting rotational kinetic energy into hydraulic energy, facilitating fluid movement through a series of impellers and volutes. Their design enables large flow rates, making them particularly effective for situations necessitating significant volumes of water to be moved swiftly.

One of the primary advantages of centrifugal pumps in energy storage lies in their high efficiency, especially under varying flow conditions. They can accommodate fluctuations in energy demand by adjusting the speed of the motor driving the pump. This adaptability is crucial since energy storage requirements may vary depending on grid conditions or consumer demand. This means that during periods of excess energy generation, the centrifugal pump can facilitate the transfer of water to higher elevations, capturing surplus energy and subsequently releasing it when required, thus ensuring seamless energy supply.

Moreover, centrifugal pumps can also be integrated into other systems, such as thermal energy storage, where they facilitate the circulation of heat transfer fluids. These systems demand reliable and efficient pumps to maintain consistent temperature levels throughout the storage medium. Thus, the versatility of centrifugal pumps as a core component across various energy storage technologies underscores their paramount significance within the sector.

3. POSITIVE DISPLACEMENT PUMPS AND APPLICATIONS

Positive displacement pumps operate on fundamental principles quite distinct from those of centrifugal pumps. These pumps move fluid by trapping a fixed amount of fluid and forcing it through the system, which allows for precise control of flow rates. This characteristic is particularly advantageous in applications where accuracy and reliability are critical, such as chemical processing and certain thermal energy storage systems.

In instances where variable flow is not an option, or consistent flow rates are essential, positive displacement pumps are often the preferred choice. For energy storage applications, they provide advantages in terms of energy efficiency since they operate effectively under a wide range of pressures and viscosities. This robustness ensures that systems employing these pumps can reliably manage energy storage and retrieval, optimizing performance and system stability.

Positive displacement pumps are also notable for their ability to handle challenging fluids. In thermal storage systems, for example, they can circulate fluids that may contain particulates or other additives without compromising the efficiency of the energy transfer process. Such capabilities make them invaluable in specialized energy storage applications where traditional centrifugal pumps may face limitations. Hence, the integration of positive displacement pumps into energy storage systems allows for greater adaptability and efficiency, contributing to a more stable energy supply.

4. HYDRAULIC PUMPS IN RENEWABLE ENERGY STORAGE

Hydraulic pumps play a substantial role in facilitating energy storage in various renewable energy systems. These mechanical devices harness hydraulic pressure, converting it into mechanical energy while simultaneously needing minimal electrical power for operation. Hydraulic systems are particularly beneficial in applications where renewable resources are harnessed, such as solar or wind, as they can effectively manage variable energy supply and demand dynamics.

The effectiveness of hydraulic pumps in energy storage is significantly influenced by their capacity to maintain high efficiency and reliability. This efficiency translates to less energy wasted during the transfer and storage processes, ultimately leading to lower operational costs for energy systems. For example, hydraulic energy storage systems often utilize hydraulic pumps to regulate pressure in underground reservoirs, greatly enhancing energy retention capabilities.

Additionally, hydraulic power can support energy storage systems by leveraging gravitational potential energy in a manner akin to pumped hydro. When harnessed correctly, these systems can exhibit substantial energy density, outperforming conventional pumping technologies in certain scenarios. This versatility underlines the significance of hydraulic pumps in the ever-evolving renewable energy landscape, where efficacy and sustainable practices are fundamental concerns.

5. INFLUENCE OF PUMP SELECTION ON ENERGY STORAGE EFFICIENCY

The selection of the right pumping technology is pivotal in determining the efficiency of energy storage systems. Not all pumps are created equal; various features, including flow rate, head pressure, and energy consumption, will ultimately impact system performance. By understanding pump characteristics, energy providers can make informed decisions that enhance the overall effectiveness of their storage capabilities.

Choosing an efficient pump design can significantly reduce energy losses during fluid transfer. For example, selecting a pump that matches the system’s required operating parameters minimizes excessive energy usage and mechanical strain on the pump components. Pumps that operate at optimal efficiency levels not only deliver better performance but also extend the pump life, reducing the need for maintenance and replacements.

In addition to mechanical efficiencies, compatibility with the overall design of the energy storage system is essential. A well-matched pump and system configuration will enable seamless integration and promote smoother energy flow. If the pumps are incompatible with the energy storage methodology, the overall system’s performance can be compromised, leading to energy losses and operational complications. Thus, selecting the appropriate pump technology based on the unique requirements of an energy storage application is vital for optimizing efficiency and effectiveness.

FREQUENTLY ASKED QUESTIONS

WHAT TYPES OF PUMPS ARE MOST COMMONLY USED IN ENERGY STORAGE SYSTEMS?

There are several types of pumps widely utilized within energy storage systems, with centrifugal and positive displacement pumps being the most prevalent. Centrifugal pumps are particularly favored in scenarios like pumped hydro energy storage due to their ability to manage large water volumes effectively. They operate on principles of rotational kinetic energy conversion and excel in high-flow applications. On the other hand, positive displacement pumps are ideal for scenarios requiring precise fluid movement. These pumps function by trapping specific quantities of fluid and driving them through the system, ensuring consistent flow rates. Each type of pump serves distinct needs within energy storage solutions, so the choice often depends on the specific operational requirements of the system.

HOW DOES PUMPING TECHNOLOGY AFFECT ENERGY STORAGE CAPABILITIES?

Pumping technology significantly impacts the efficiency and overall effectiveness of energy storage systems. The right pump can enhance energy retention and retrieval processes, minimizing energy losses during fluid transfer while maximizing energy conversion efficiencies. For instance, pumps designed for optimal performance in specific scenarios can maintain higher flow rates and lower power consumption, consequently leading to lower operational costs. Additionally, maintaining a balance between pump selection and fluid properties plays a vital role, as the efficiency of the pumping process directly influences the overall capacity and performance of energy storage solutions. Ultimately, effective pump design and integration enable energy storage systems to operate seamlessly, responsive to fluctuating energy demands.

CAN PUMPS IN ENERGY STORAGE APPLICATIONS BE RELIED UPON FOR LONG-TERM PERFORMANCE?

The longevity and reliability of pumps in energy storage applications are influenced by several factors, including pump design, materials used, and the conditions under which they operate. When correctly specified and installed, pumps can provide long service life and consistent operation, essential for maintaining the dependability of energy storage systems. Regular maintenance practices, such as inspections and timely replacement of wear components, further enhance reliability. Moreover, understanding the specific operational environment, such as fluid temperature and potential contaminants, allows for better pump selection, ensuring that the system operates efficiently for extended periods without disruptions. Consequently, investing in quality pump technology and maintenance strategies is essential for sustaining the long-term performance of energy storage solutions.

Selecting appropriate pumps for energy storage systems represents a crucial aspect of improving efficiency and performance across various applications. The diverse types of pumping technologies, from centrifugal to positive displacement and hydraulic pumps, each offer unique advantages suited to specific energy storage strategies. Understanding the intricate operational dynamics of these pumps and their relationship with energy storage capabilities can lead to significant improvements in overall system effectiveness. Future advancements in pump technology, alongside the increased integration of renewable energy sources, will continue to revolutionize energy storage solutions, reinforcing the need for diligent research and development in pump design and efficiency. By investing in capable pumping technologies and ensuring compatibility with energy storage systems, stakeholders can maximize energy retention, decrease operational costs, and promote sustainable practices essential for a glimmering energy future. Thus, it is imperative that experts within the energy sector remain cognizant of evolving pump technologies to stay ahead in this rapidly changing landscape.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-the-pumps-used-in-energy-storage-equipment/