Solar refrigeration tubes utilize a variety of materials that enhance their efficiency and durability. 1. Common materials include copper, aluminum, borosilicate glass, and various polymers, which play crucial roles in thermal conductivity, strength, and resistance to environmental factors. 2. Each material offers specific advantages, such as copper providing excellent heat transfer properties, while borosilicate glass offers durability against thermal shock. 3. Advances in material science have led to innovations that improve the performance of solar refrigeration systems, such as coatings that enhance absorption and materials that withstand harsh weather conditions. 4. Understanding these materials is essential for optimizing the design and functionality of solar refrigeration systems.

1. UNDERSTANDING SOLAR REFRIGERATION TUBES

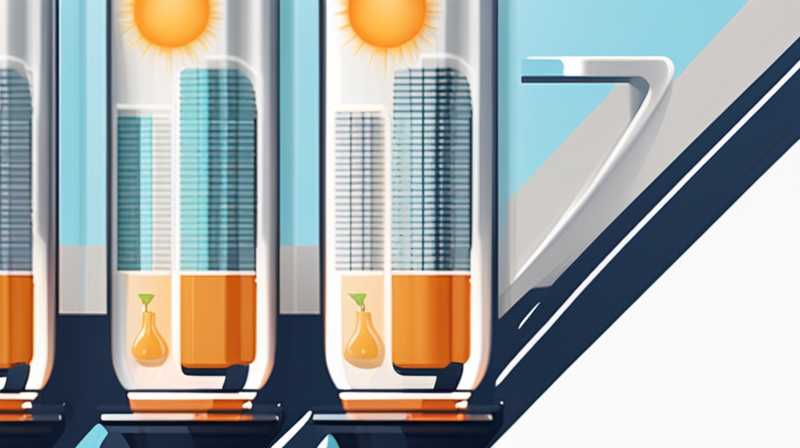

Solar refrigeration tubes are integral components of solar thermal systems designed to harness solar energy for refrigeration and cooling purposes. Their primary function is to absorb sunlight, converting it into thermal energy, which can then be utilized for cooling applications. In essence, these tubes are engineered to capture and transfer heat efficiently, making them pivotal in renewable energy systems.

The construction of these tubes is crucial for their effectiveness. Choosing the right materials impacts both the performance and longevity of the system. With a growing global emphasis on sustainability, solar refrigeration tubes represent a significant step towards reducing reliance on fossil fuels while promoting greener energy solutions. Understanding the materials used in these tubes can help in selecting optimal configurations for various applications, from residential to industrial scales.

The effectiveness of solar refrigeration hinges greatly on the materials employed. Manufacturers are continuously exploring innovative materials to enhance the efficiency and performance of these systems. As climate change poses increasing challenges, the shift toward sustainable technologies such as solar refrigeration is urgent.

2. MATERIALS USED IN SOLAR REFRIGERATION TUBES

2.1 COPPER

Copper is one of the most commonly used materials in solar refrigeration tubes due to its outstanding thermal conductivity. This property allows for rapid heat absorption and efficient transfer, enabling the system to quickly convert solar energy into usable refrigeration. Furthermore, copper is resistant to corrosion, which is essential for the longevity of the components exposed to varying environmental conditions.

The malleability of copper also facilitates easy manipulation during the manufacturing process, leading to diverse designs and configurations. Its durability along with excellent heat transfer capabilities makes it a preferred choice among manufacturers. While the initial cost of copper may be higher than some other materials, the long-term benefits – such as reduced energy consumption and improved system efficiency – often justify this investment. Sustainability considerations also come into play, as copper is 100% recyclable and does not lose its properties during the recycling process.

2.2 ALUMINUM

Aluminum serves as another prominent material in solar refrigeration tubes. Lightweight and corrosion-resistant, aluminum is often chosen for its favorable weight-to-strength ratio. These properties make it easier for installation while maintaining structural integrity. Aluminum tubes are versatile and can be extruded into various shapes and sizes to meet specific design requirements.

Moreover, aluminum has commendable thermal properties, though slightly less effective than copper. However, its lower cost compared to copper makes it an attractive option for manufacturers, especially for large-scale installations. Innovations in aluminum alloy formulations have further enhanced its thermal conductivity, leading to improved performance in solar refrigeration applications. Its increased use marks a trend towards broader applications in sustainable technologies, aligning with environmental goals.

2.3 BOROSILICATE GLASS

Borosilicate glass represents a significant advancement in the materials used for solar refrigeration. Known for its high resistance to thermal shock, borosilicate glass ensures that the tubes are durable and can withstand extreme temperature fluctuations without risk of breakage. This property is particularly important in varying climates where thermal stress might compromise the structure of the tubes.

Furthermore, borosilicate glass is highly transparent, allowing for maximum sunlight penetration while minimizing losses due to reflection. Its inert nature ensures that it does not react with the contents inside the tubes, promoting a safer and more reliable refrigeration process. The elegant combination of durability and efficiency makes borosilicate glass an ideal candidate for advanced solar refrigeration technologies.

2.4 POLYMERS

Polymers have found a niche application in the construction of solar refrigeration tubes. Materials like polyethylene and polypropylene are employed in various components due to their light weight and resistance to corrosion. While not commonly used for the main tube structures, these polymers can play a significant role in auxiliary components, such as insulation and gaskets.

The development of advanced composite polymers has led to materials that can withstand high-pressure and high-temperature environments, making them suitable for innovative designs in solar refrigeration systems. The flexibility of polymer materials also opens up potential for novel configurations that can enhance the adaptability of solar refrigeration technologies.

3. ADVANCEMENTS IN MATERIAL SCIENCE FOR SOLAR REFRIGERATION

3.1 COATINGS AND FINISHES

Recent advancements in materials science have led to the development of specialized coatings and finishes for solar refrigeration tubes. These coatings can significantly enhance the absorption capacity of the tubes, allowing for greater conversion of sunlight into thermal energy. Such innovations include selective coatings that improve the efficiency of solar energy absorption while minimizing heat loss.

These coatings are typically applied to materials like copper and aluminum, which are chosen precisely for their excellent thermal properties. When combined with advanced coatings, these materials can achieve efficiencies that surpass traditional configurations. As technology continues to evolve, ongoing research into these coatings aims to optimize performance and durability, thereby enhancing the reliability of solar refrigeration systems.

3.2 RECYCLED MATERIALS

The focus on sustainability has prompted manufacturers to explore the use of recycled materials in solar refrigeration tubes. Using recycled metals and polymers not only reduces the environmental footprint of production but also provides cost-effective solutions without sacrificing quality. Recycling processes for metals like aluminum and copper have become increasingly efficient, enabling significant energy savings and resource conservation during production.

This trend presents a remarkable opportunity for the solar industry, as the reduced reliance on virgin materials aligns with global environmental goals. Employing recycled materials can also influence public perception and customer choice, as environmentally conscious consumers increasingly gravitate toward sustainable products. Emphasizing the incorporation of recycled materials in solar refrigeration systems reflects a commitment to a greener future.

4. OPTIMIZING SOLAR REFRIGERATION TUBE DESIGNS

4.1 DESIGN INNOVATIONS

Innovative designs in solar refrigeration tubes are emerging as technology progresses. The geometry of the tubes can significantly influence their performance, impacting factors like fluid circulation and heat transfer efficiency. Manufacturers are investigating forms that optimize these aspects, leading to the development of multi-tube configurations or varying diameters to suit different applications.

Such design modifications can lead to enhanced thermal accumulation and greater system efficiency. Additionally, the integration of intelligent design elements, such as adjustable orientations that can adapt to the sun’s movement, holds great potential for maximizing energy capture. The exploration of these advanced design concepts continues to influence the evolution of solar refrigeration technologies, promising improved outcomes for users.

4.2 INTEGRATION WITH OTHER TECHNOLOGIES

To further extend the capability and application of solar refrigeration tubes, manufacturers are exploring integration with complementary technologies. This includes pairing solar refrigeration systems with geothermal energy or coupling them with innovative energy storage solutions. The synergy created through such integrations can lead to energy-efficient systems that can provide consistent cooling, even during periods of low solar availability.

Implementing hybrid systems enhances the resilience and efficiency of solar refrigeration, making them viable options for a broader range of applications. As energy demands continue to grow, integrating solar refrigeration tubes with other renewable technologies could pave the way for groundbreaking solutions that address global cooling challenges sustainably.

5. LONG-TERM PERFORMANCE AND SUSTAINABILITY

5.1 MAINTENANCE CONSIDERATIONS

While the materials used in solar refrigeration tubes play a pivotal role in their effectiveness, long-term performance hinges on proper maintenance. Regular oversight, including inspections and necessary repairs, ensures that the systems operate at peak efficiency. Addressing wear and tear on various components, particularly seals and insulation, contributes to sustaining the system’s overall efficacy.

Moreover, while selecting materials known for durability can minimize maintenance needs, it is equally important for users to understand the specific maintenance requirements of their solar refrigeration setup. Building awareness surrounding these practices not only enhances operational longevity but also instills confidence in the effectiveness of solar energy solutions.

5.2 ENVIRONMENTAL IMPACT AND LIFE CYCLE ANALYSIS

Understanding the life cycle impact of the materials involved in solar refrigeration is essential. Conducting life cycle assessments helps gauge the true environmental footprint of manufacturing, using, and disposing of solar refrigeration tubes. A robust analysis can reveal areas for improvement, from sourcing raw materials to end-of-life disposal.

With an emphasis on sustainability, evaluating materials based on their environmental impact throughout their life cycle can influence choices at the manufacturing stage. It encourages the adoption of eco-friendly materials and processes while reinforcing a commitment to environmental stewardship. This holistic approach to assessing and optimizing the use of materials in solar refrigeration exemplifies the critical intersection of technology and sustainability.

FAQS

WHAT ARE THE KEY BENEFITS OF COPPER IN SOLAR REFRIGERATION TUBES?

Copper has been a mainstay material in solar refrigeration tubes primarily due to its superior thermal conductivity, which enables efficient heat transfer from the sun to the refrigeration medium. This quality ensures that solar energy is utilized effectively, resulting in enhanced cooling performance. Furthermore, copper exhibits remarkable durability and resistance to corrosion, ensuring the longevity of solar refrigeration systems even in harsh environments.

The ability to easily shape and mold copper allows manufacturers to create customized geometries that optimize thermal absorption and fluid dynamics. In addition to its performance characteristics, copper is recyclable, aligning with sustainability goals in the manufacturing processes. This characteristic combines environmental responsibility with high-performance materials in the renewable energy sphere. Recognizing copper’s value helps promote its use in advancing solar refrigeration technology.

HOW DOES BOROSILICATE GLASS IMPACT THE PERFORMANCE OF SOLAR REFRIGERATION TUBES?

Borosilicate glass significantly enhances the performance and operational efficiency of solar refrigeration tubes due to its unique properties. Its high thermal shock resistance minimizes the risk of breakage, especially in areas exposed to rapid temperature changes. This durability grants manufacturers confidence in the reliability of the refrigeration system over time.

Furthermore, borosilicate glass offers excellent transparency, facilitating optimal sunlight penetration for energy absorption. This characteristic ensures that the solar collector operates at peak efficiency throughout the day. As a non-reactive material, borosilicate glass does not alter or contaminate the refrigerants within. The important safety consideration underscores its suitability for direct exposure to solar energy. In summary, borosilicate glass substrates are advantageous for ensuring efficient, reliable, and safe operation in solar refrigeration applications.

WHAT ADVANCES IN POLYMER TECHNOLOGY SUPPORT SOLAR REFRIGERATION TUBES?

Recent innovations in polymer technology have provided enhanced materials that greatly benefit the design and function of solar refrigeration tubes. Modern polymers are engineered for high-temperature and high-pressure applications, allowing them to be utilized in various auxiliary components integral to the refrigeration process. This expanded applicability is vital for improving insulation and minimizing heat loss in the system.

Additionally, recycled polymers are gaining traction as manufacturers seek eco-friendly solutions. Advanced recycling techniques yield quality materials that maintain strength and durability, reducing the environmental impact of production. Innovations such as thermoplastic elastomers further improve flexibility while offering superior resistance to environmental factors. Together, these polymer advancements contribute to the evolution of solar refrigeration tube systems, aligning with broader sustainability objectives.

FINAL THOUGHTS ON MATERIALS IN SOLAR REFRIGERATION TUBES

The materials utilized in solar refrigeration tubes play an essential role in determining the overall efficiency, durability, and sustainability of these innovative systems. Given the growing demand for renewable energy solutions, understanding the specifics regarding the materials involved is paramount. Copper and aluminum dominate the landscape for their thermal properties and structural advantages, while borosilicate glass contributes significant benefits in terms of safety and heat retention.

Polymers, with their burgeoning advancements, provide additional opportunities for enhancing solar refrigeration technology, particularly in auxiliary roles. The continuous exploration of innovations such as coatings, advanced materials, and recycled components reflects a commitment to improving efficiency while addressing environmental concerns.

The intersection of material science and solar technology presents exciting possibilities to ensure the effectiveness and longevity of solar refrigeration systems. As consumers and manufacturers alike embrace renewable energy concepts, the ongoing research and development of materials will undeniably influence the path towards a sustainable future. Engaging with this subject is crucial for stakeholders looking to optimize their investment and positively impact energy consumption trends in diverse sectors.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-the-materials-of-solar-refrigeration-tubes/