1. Solar panel beads are primarily constructed from silicon, glass, metals, and plastic. Each material plays a vital role in the efficiency and functionality of solar panels. A pivotal component is silicon, which serves as the primary semiconductor in solar cells and greatly influences energy conversion efficiency. Silicon’s unique properties allow it to absorb sunlight and convert it into electricity effectively, making it an essential element in the solar panel manufacturing process.

- MATERIAL ANALYSIS OF SOLAR PANEL COMPONENTS

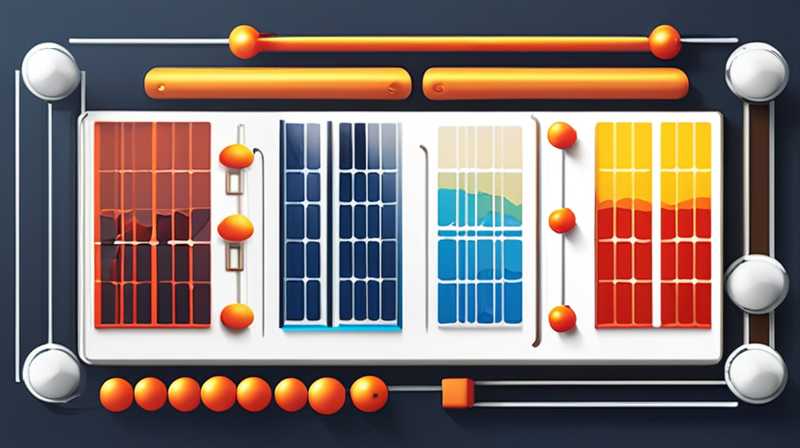

Solar panel beads, or solar cells, consist of numerous materials that together enable their operation. Each constituent offers specific characteristics and contributes uniquely to overall efficiency and durability. Understanding the composition of these materials provides insight into the workings of solar technology and advances its development.

SILICON: THE HEART OF SOLAR CELLS

The foundation of most solar panel beads lies in silicon, a semiconductor that proves essential for converting sunlight into electrical energy. Silicon is commonly used in two primary forms: monocrystalline and polycrystalline. Monocrystalline silicon solar panels are made from a single crystal structure, which offers high efficiency and longevity. They typically yield better performance in low-light and high-temperature conditions, making them suitable for various applications.

In contrast, polycrystalline silicon is produced from multiple silicon crystals. While it is generally less efficient than monocrystalline silicon, it is often more cost-effective and presents an appealing option for budget-conscious consumers. Understanding the distinctions between these two types allows consumers to select appropriate solar technology based on their specific energy needs, budget, and installation environment.

GLASS: PROTECTING SOLAR CELLS

The protective outer layer of solar panel beads is primarily composed of tempered glass, which serves multiple functions. First, this element acts as a barrier against environmental factors, such as rain, hail, dust, and airborne particles. This protective layer also provides structural integrity against physical impacts, thereby prolonging the life span of the solar panel.

Additionally, tempered glass has a high transmission rate that allows maximum sunlight exposure to the solar cells, contributing to overall efficiency. Features such as anti-reflective coatings can further improve light absorption, enhancing the cell’s ability to generate electricity. The use of high-quality tempered glass not only ensures longevity but also optimizes the performance of solar panel beads.

METALS: CONDUCTIVITY AND SUPPORT

Various metals are also integrated into solar panel design, chiefly aluminum and copper. Aluminum is utilized for framing components that support the solar cells and protect them from mechanical damage while allowing for lightweight construction. The structural advantage presented by aluminum facilitates easier installation and modifications, enhancing user flexibility.

Copper, on the other hand, is integral to the electrical connections within solar panels. Its superior conductivity ensures minimal energy loss during transmission, improving energy efficiency. Furthermore, copper’s corrosion resistance contributes to the longevity of electrical pathways within solar panel systems, underscoring its importance in the effective performance of solar technology.

PLASTICS: INSULATION AND PROTECTION

To enhance durability and insulation, plastic materials are incorporated into solar panel beads. Various plastic components, such as back sheets and junction boxes, protect the sensitive electronics from moisture, dust, and other potential environmental hazards. These back sheets, generally made from polymer materials, provide electrical insulation and contribute to maintaining the panel’s overall structural integrity.

Additionally, plastics serve a critical function in minimizing energy loss through insulation. By creating barriers that reduce thermal conductivity, plastics help to maintain optimal operating temperatures for solar cells, thus maximizing energy production. Employing high-quality plastics in solar panel manufacturing is crucial to developing high-efficiency panels that can withstand diverse environmental conditions.

INNOVATIVE MATERIALS: ADVancements in Solar Technology

In recent years, advancements in solar technology have paved the way for the exploration of alternative materials that could further enhance efficiency. Researchers are investigating the use of perovskite materials in solar cells, which promise to deliver higher efficiency rates at a fraction of the cost of traditional silicon-based panels.

Perovskite solar cells have emerged as promising contenders due to their unique crystal structure, which allows for effective light absorption and conversion into electricity. The tunability of perovskite materials also enables researchers to engineer specific properties to tailor cells for different applications. If successfully developed, perovskite technologies may revolutionize solar energy by enabling the commercialization of solar panels at an unprecedented scale and efficiency.

- COMMONLY ASKED QUESTIONS

WHAT ARE THE MAIN COMPONENTS OF SOLAR PANEL BEADS?

The primary constituents of solar panel beads include silicon, tempered glass, various metals (like aluminum and copper), and plastics. Silicon serves as the main semiconductor, pivotal in converting sunlight into electricity. The tempered glass protects the solar cells while allowing maximum light transmission. Metals provide structural support and electrical conductivity essential for efficient energy production, and plastics contribute to insulation and protection against environmental hazards. Understanding these components reveals how they work in unison to optimize solar panel performance. Each material is carefully chosen for its properties, ensuring the panels can withstand diverse conditions while promoting high energy efficiency. The interaction of these various materials also plays a vital role in the overall effectiveness and reliability of solar technology. By advancing the manufacturing processes of these components, the solar industry continuously seeks to improve the efficiency and deployments of solar energy solutions.

HOW DO MATERIALS AFFECT SOLAR PANEL EFFICIENCY?

The efficiency of solar panels is significantly influenced by the materials used in their construction. For instance, the type of silicon—monocrystalline, polycrystalline, or thin-film—directly affects energy conversion rates. Monocrystalline panels generally achieve higher efficiencies due to their uniform structure. Tempered glass ensures minimal reflection and maximum sunlight absorption, contributing positively to overall performance. The metals incorporated into the panel, notably copper and aluminum, also impact energy loss during transmission and strength, affecting how much energy a given solar panel can produce. Additionally, emerging materials, such as perovskites, offer exciting potential for future improvements in efficiency. These innovative materials have shown promises in laboratory settings, suggesting that they may become viable competitors to traditional silicon-based technologies in the near future. As technological advancements continue, the ability to select and utilize high-performance materials will be crucial in maximizing solar energy production and its integration into sustainable energy systems.

WHAT ARE THE BENEFITS OF USING ALTERNATIVE SOLAR PANEL MATERIALS?

Exploring alternative materials for solar panels, such as perovskites or organic photovoltaics, offers several benefits. One primary advantage is enhanced efficiency at reduced production costs. For instance, perovskite materials can be manufactured with lower energy inputs compared to traditional silicon methods, decreasing environmental impact and allowing for economically viable solutions. Additionally, these alternative materials often present better performance in low-light conditions, making them suitable for a wider range of applications. Flexibility in design and materials can lead to lightweight solar panels, which are easier to install and integrate into existing structures. Moreover, further research into these cutting-edge materials may be accompanied by breakthroughs in recycling and sustainability, promoting a circular economy within the solar industry.

In summary, the materials that constitute solar panel beads play critical roles in determining their effectiveness and longevity. Each element—silicon, glass, metals, and plastics—contributes uniquely to the system, promoting energy conversion efficiency and resilience against environmental factors. Silicon remains the dominant and essential semiconductor, but the industry is increasingly exploring alternative materials, such as perovskites, to enhance performance and reduce costs. The intricate relationship among these components highlights the ongoing research and innovation within the solar energy sector, reinforcing the importance of material selection in achieving sustainable solutions for the future. As technological advances proceed, developing new materials and improving existing ones will be integral to expanding the reach of solar energy and promoting its adoption as a reliable alternative to traditional energy sources. This sustained evolution will likely influence global energy strategies and contribute to a cleaner, more sustainable energy ecosystem.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-the-materials-of-solar-panel-beads/