1. FACTORY ENERGY STORAGE SYSTEMS ARE INCREASINGLY IMPLEMENTED TO ENHANCE ENERGY EFFICIENCY AND SUSTAINABILITY. THIS SYSTEM ENABLES MORE EFFECTIVE MANAGEMENT OF ENERGY RESOURCES, REDUCES OPERATIONAL COSTS, AND CONTRIBUTES TO ENVIRONMENTAL CONSERVATION. 2. KEY ADVANTAGES INCLUDE OPTIMIZED ENERGY USE, PEAK LOAD SHAVING, INCREASED SYSTEM RELIABILITY, AND MITIGATED GRID IMPACT. 3. THE TECHNOLOGIES USED RANGE FROM LITHIUM-ION BATTERIES TO FLOW BATTERIES, EACH WITH DISTINCT CHARACTERISTICS AND REQUIREMENTS. 4. THIS CONCEPT ALSO SERVES AS A FOUNDATION FOR INTEGRATING RENEWABLE ENERGY SOURCES INTO THE MANUFACTURING PROCESS.

1. INTRODUCTION TO ENERGY STORAGE IN INDUSTRIAL SETTINGS

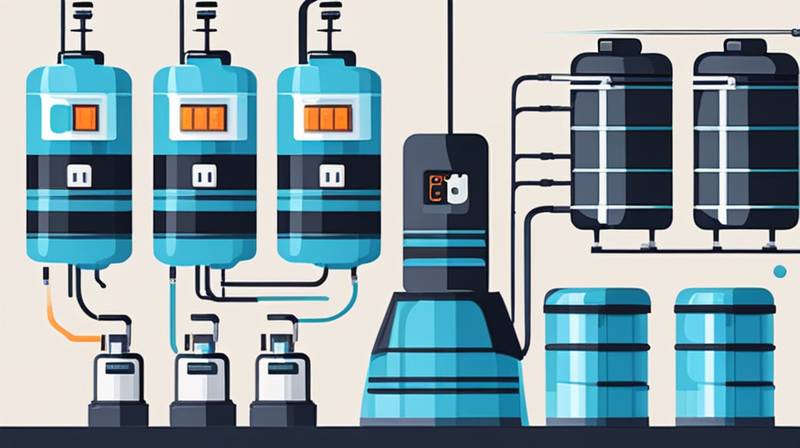

Within the realm of modern manufacturing, efficiency and sustainability have become paramount considerations. Energy storage systems, particularly those tailored for factory contexts, facilitate a transformation in how energy consumption is managed. By harnessing excess energy generated during peak production times, these systems allow factories to decouple energy use from direct consumption requirements.

Energy storage encompasses a variety of technologies designed to store energy for later use. This capability not only stabilizes operations but also enhances the overall resilience of manufacturing processes against the intricacies of fluctuating energy demands. The adoption of these systems is not purely a trend but a strategic move towards operational efficiency and ecological responsibility.

2. IMPORTANCE OF ENERGY STORAGE IN MANUFACTURING

The implementation of energy storage solutions plays a crucial role in enhancing overall manufacturing efficacy. When energy is stored during off-peak hours and utilized during periods of high demand, factories can achieve considerable cost savings. This practice, known as peak load shaving, helps avoid the surges often seen during peak operational hours, leading to more stable energy pricing.

Moreover, by adopting energy storage systems, organizations can significantly reduce their dependency on external power sources. This reduces exposure to potential energy price spikes and fosters an environment where firms can operate with greater autonomy. The long-term viability of business operations is thus fortified through a strategic pivot towards self-sufficient energy practices.

3. TYPES OF ENERGY STORAGE TECHNOLOGIES

A diverse array of energy storage technologies is available, each possessing unique benefits suitable for varying manufacturing environments.

3.1. LITHIUM-ION BATTERIES

Lithium-ion batteries are the most widely used type within industrial storage applications. Their high energy density means they can store a substantial amount of energy in a relatively compact form. They enable rapid charge and discharge cycles, making them particularly effective for applications requiring quick bursts of energy.

Despite their advantages, there are challenges associated with lithium-ion technologies, including cost, recyclability, and safety concerns. These batteries may present risks if not handled correctly, particularly in terms of thermal management. Furthermore, their disposal poses environmental challenges, necessitating the development and implementation of focused recycling programs.

3.2. FLOW BATTERIES

In contrast to lithium-ion batteries, flow batteries provide a distinctive solution through the use of two chemical components dissolved in liquids, separated by a membrane. This design allows for scalability; the energy capacity can be increased by simply augmenting the size of the storage tanks.

Flow batteries excel in applications where long discharge times are a necessity. They present a viable solution for companies seeking to integrate renewable energy sources, such as solar or wind, effectively. As energy from these sources is often variable, the ability of flow batteries to store energy for longer periods allows for smoother integration with manufacturing processes.

4. STRATEGIC BENEFITS OF DEPLOYING ENERGY STORAGE SYSTEMS

Implementing energy storage systems provides a plethora of strategic advantages that enhance the operational landscape of factories.

4.1. COST REDUCTIONS

One of the primary benefits of energy storage systems is the reduction of energy costs. Factories can optimize their energy usage by storing electricity when rates are low and subsequently drawing on that stored energy during high-demand periods, minimizing expenditures associated with peak pricing. This strategy not only fosters cost savings but also promotes more predictable budgeting for energy needs.

4.2. ENHANCED RELIABILITY

Manufacturing processes are highly sensitive to interruptions in power supply. Energy storage systems mitigate this vulnerability by providing backup support in situations of grid instability or power outages. By ensuring a consistent energy supply, factories can maintain higher productivity levels and avoid costly downtime.

5. INTEGRATION WITH RENEWABLE ENERGY SOURCES

As the push for sustainability intensifies, integrating renewable energy sources with energy storage systems has gained traction in industrial settings. This integration facilitates a smoother transition towards greener manufacturing processes without compromising energy reliability.

5.1. SUPPORTING SOLAR AND WIND ENERGY

By utilizing energy storage systems in tandem with solar panels or wind turbines, factories can capture renewable energy produced during favorable conditions. This stored energy can then be utilized when renewable generation is low, such as during cloudy days or calm periods, thereby ensuring a constant energy supply while simultaneously reducing reliance on fossil fuels.

5.2. GOVERNMENT INCENTIVES AND SUPPORT

Many governments are offering incentives to stimulate the adoption of renewable energy sources paired with energy storage systems. Entities that invest in these technologies may qualify for funding, tax credits, or rebates. This government support acts as a significant driver for manufacturers to transition toward sustainable practices and reduce their carbon footprint.

6. CHALLENGES AND CONSIDERATIONS

While the advantages of implementing energy storage systems in factories are substantial, there are also challenges manufacturers must confront.

6.1. INITIAL INVESTMENT

The initial investment required for implementing effective energy storage solutions can be considerable, often posing a barrier for smaller manufacturers. Operational shifts need to be evaluated against potential long-term savings, and decision-makers must balance short-term financial pressures with the long-term viability offered by energy storage technologies.

6.2. Technical Complexity

Navigating the installation and integration of energy storage systems involves understanding complex technological specifications. Factories must ensure they have the capacity and expertise necessary to manage these systems adequately; otherwise, the desired benefits may not be realized.

7. ENVIRONMENTAL IMPACT

As factories become increasingly aware of their ecological footprint, energy storage systems provide an opportunity for significant environmental benefits.

7.1. REDUCED CARBON EMISSIONS

By integrating renewable energy sources and enhancing energy efficiency through storage solutions, manufacturing facilities can markedly reduce their carbon emissions. This reduction not only contributes to climate change mitigation but also enhances a company’s public image by demonstrating commitment to sustainable practices.

7.2. Resource Conservation

Energy storage can lead to better resource management. With the ability to store energy when it is abundant and utilize it during shortages, factories can lessen their overall energy consumption and contribute to a more sustainable resource management approach.

8. CASE STUDIES OF ENERGY STORAGE DEPLOYMENT

Real-world applications of energy storage technologies provide valuable insights into their benefits and effectiveness within manufacturing environments.

8.1. TESLA’S ROLE IN INDUSTRIAL STORAGE

Tesla has emerged as a notable player in the energy storage market, providing innovative solutions tailored for industrial applications. Their systems not only offer extensive battery storage but also enable integration with smart grid technologies, promoting more efficient energy workflows.

Businesses incorporating Tesla’s systems have reported considerable cost reductions and enhanced sustainability measures, demonstrating the practical benefits of adopting this technology. Case studies function as a testament to the growing trend of energy storage in industrial landscapes.

8.2. EXAMPLES FROM THE AUTOMOTIVE SECTOR

The automotive sector has also witnessed substantial gains through energy storage integration. Companies like Ford and General Motors are investing in large-scale battery systems to manage energy demands throughout production lines. These advancements allow for rapid responses to changes in energy availability and lead to improved operational efficiencies.

By examining such implementations, other manufacturers can glean strategic insights into effectively adopting energy storage solutions conducive to their unique production environments.

9. Future Prospects of Energy Storage in Factories

Looking ahead, the role of energy storage within the manufacturing paradigm is poised for substantial evolution.

9.1. ADVANCES IN BATTERY TECHNOLOGY

As technological advancements continue to emerge, manufacturers can anticipate more efficient and cost-effective energy storage solutions entering the marketplace. Innovations in battery materials and designs promise improved performance and lifespan, facilitating broader adoption across different manufacturing sectors.

9.2. REGIONAL REGULATIONS AND STANDARDS

With growing environmental regulations, factories will be increasingly incentivized to adopt energy storage systems to meet compliance. Policymakers are likely to create frameworks that reward sustainable practices, driving further investments into energy efficiency improvements.

OFTEN ASKED QUESTIONS

IS IMPLEMENTING AN ENERGY STORAGE SYSTEM WORTH THE INVESTMENT?

Investing in an energy storage system offers potential for significant cost savings over time through reduced energy costs and peak demand management. While initial expenses may be substantial, the return on investment is often realized as manufacturers optimize their energy use and minimize reliance on external suppliers. Ancillary benefits, such as increased system reliability and enhanced environmental sustainability, further establish the system’s value. The decision ultimately hinges on evaluating individual operational needs, expected savings, and long-term financial benefits associated with self-sustaining energy practices.

HOW DOES ENERGY STORAGE IMPACT A FACTORY’S SUSTAINABILITY EFFORTS?

Energy storage plays a pivotal role in complementing a factory’s sustainability initiatives. By enabling the effective use of renewable energy resources, energy storage systems help factories reduce their carbon footprint and dependence on fossil fuels. Furthermore, this capability supports initiatives in energy conservation and promotes resource efficiency, fostering a more sustainable approach to manufacturing. When properly implemented, energy storage can serve as an integral component of a factory’s commitment to environmentally responsible practices by delivering reliable energy, aligning operational efficiencies with sustainability goals.

WHAT FACTORS INFLUENCE THE CHOICE OF ENERGY STORAGE TECHNOLOGY?

Choosing the appropriate energy storage technology hinges on several factors, including the specific energy demands of the factory, the available budget, and existing infrastructure. Each technology has distinct features, such as power density, cost, scalability, and operational lifetime. For instance, facilities requiring quick response times may favor lithium-ion batteries, while those needing long-duration energy storage may lean towards flow batteries. Organizations must conduct a comprehensive analysis of their energy profiles, operational objectives, and financial constraints to determine the most suitable energy storage solution that complements their manufacturing activities.

Integration of energy storage systems within factories is vital for future operational success. The multifaceted benefits they provide extend beyond mere financial advantages; they foster sustainability, resilience, and innovation within manufacturing landscapes. By optimizing energy management, companies can not only reduce costs but also create a robust framework for environmentally responsible production practices that resonate positively within the broader community. As the landscape of energy production and consumption continues to evolve, the strategic incorporation of energy storage will redefine the operational paradigms of factories worldwide. Manufacturers must prioritize adaptability and innovation, ensuring that they are not only aligned with current trends but also poised to embrace the future. The ongoing advancements in energy storage technologies will provide even greater opportunities for factories to enhance productivity and reduce their environmental impact, ensuring a sustainable and prosperous manufacturing landscape for generations to come.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-the-key-points-of-factory-energy-storage-system/