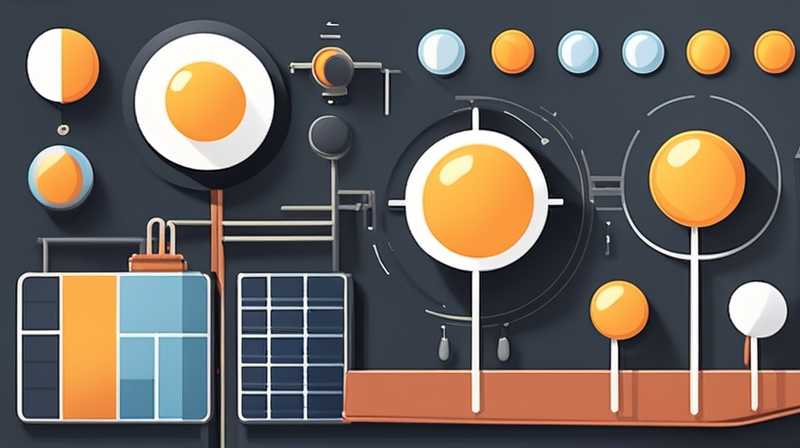

The ingredients of solar panels primarily consist of 1. silicon, 2. metals, 3. glass, 4. polymers, and 5. anti-reflective coatings. Silicon is the primary material used in the production of photovoltaic cells. It is abundant, efficient in converting sunlight into electricity, and can be found in two major forms: monocrystalline and polycrystalline. Metals, such as aluminum and copper, are crucial for electrical conductivity, connecting the cells, and providing structural support to the panels. Glass serves to protect the cells while allowing sunlight to penetrate effectively. Polymers are used for encapsulation and protecting the components from environmental factors. Anti-reflective coatings enhance efficiency by minimizing light reflection. Of these, silicon is the most significant ingredient due to its essential role in the solar cell’s function and conversion efficiency, making it the backbone of the majority of solar panel technology utilized today.

1. UNDERSTANDING SOLAR PANEL COMPONENTS

The ingredients of solar panels are pivotal elements that contribute to their efficiency and overall performance. Each component serves a distinctive purpose, enabling solar panels to convert sunlight into usable electricity. The most crucial ingredient is silicon, which forms the basic structure of solar cells. Silicon solar cells dominate the market due to their efficiency rates, longevity, and the well-established technology surrounding their production. This material can be found in two main forms: monocrystalline and polycrystalline, both of which exhibit unique characteristics suitable for various applications.

Monocrystalline silicon cells, made from single-crystal structures, tend to be more efficient and are characterized by their sleek appearance. They often generate more electricity per square meter and perform better under low-light conditions. However, the manufacturing process is more intricate and requires a higher level of energy input during fabrication. Conversely, polycrystalline silicon cells, composed of multiple silicon crystals, are generally less expensive to produce but are slightly less efficient. Their cost-effectiveness makes them a popular choice for larger solar installations where space might not be a constraint. Understanding these fundamental properties of silicon is crucial when discussing solar panel performance.

2. METALS AND THEIR ROLE IN SOLAR PANELS

Metals play an integral role in the construction and functionality of solar panels. Aluminum primarily forms the frame, providing structural support, which is essential for durability during inclement weather conditions. Its lightweight characteristics facilitate easier handling and installation, while its corrosion resistance ensures longevity. Furthermore, aluminum’s price point makes it an attractive option compared to more expensive metals, supporting the overall affordability of solar panels.

In contrast, copper is utilized in the electrical connections within the solar cells. Copper possesses exceptional electrical conductivity, which is essential for the efficient transfer of the electricity generated by photovoltaic cells to the inverter system. Copper wire helps to minimize energy losses, ensuring that as much of the generated power as possible can be utilized. The dual role of aluminum and copper emphasizes the importance of metals in optimizing solar panel performance, ensuring that the infrastructure can withstand environmental challenges while providing efficient energy transfer.

3. GLASS: THE PROTECTIVE LAYER

Glass serves multiple essential functions in solar panel construction. Tempered glass, typically used in solar panels, is specially treated to enhance its strength and impact resistance. This characteristic is vital for protecting the delicate silicon cells from environmental stressors like hail or high winds while simultaneously allowing sunlight to penetrate effectively. With the increasing concerns around the durability of solar panels, research and technology advancements have led to the development of glass materials that can minimize reflectivity while maximizing light transmission.

Moreover, the surface of the glass is coated with an anti-reflective layer. This coating significantly reduces the amount of sunlight that is reflected away and not absorbed by the solar cells. By optimizing the amount of light that reaches the silicon cells, the efficiency of energy conversion is notably improved. The role of glass in solar panels extends beyond mere protection; it plays a crucial part in enhancing the overall efficiency and performance, which is essential for both residential and commercial applications.

4. POLYMERS AND THEIR CONTRIBUTIONS

The use of polymers in solar panels is primarily found in the encapsulation process. These materials protect sensitive components, allowing for resilience against environmental factors such as moisture and dirt. The encapsulation process involves sandwiching the solar cells between layers of polymer, ensuring a robust and protective barrier is formed. This seal is critical as it maintains performance efficiency by preventing potential degradation over time due to exposure to climate conditions.

Additionally, polymers are utilized in backsheet materials, acting as insulators to protect electrical components from heat and moisture. The significance of polymers extends to their lightweight nature, which contributes to the overall efficiency of solar panel installations. As advancements in polymer technology continue, the potential for enhanced durability and performance in solar panels grows, allowing for improved efficiency and longevity of solar energy systems, thus encouraging wider adoption.

5. ANTI-REFLECTIVE COATINGS AND THEIR IMPACT

Anti-reflective coatings maintain a crucial role in boosting the performance of solar panels by refining the interaction between light and silicon cells. These coatings are applied to the surface of the glass and serve to diminish the reflection of sunlight. Without such coatings, significant portions of sunlight could be lost due to reflection instead of absorption, negatively affecting the overall efficiency of the solar panel.

The effectiveness of anti-reflective coatings can directly influence the energy yield of solar panels. By increasing the amount of light absorbed by the solar cells, they allow for better performance during varying atmospheric conditions, such as overcast days. Advanced research continues to improve these coatings, leading toward innovations that optimize solar energy capture. The fusion of quality anti-reflective coatings with conventional solar technologies ultimately strengthens the viability of solar energy as an integral power source in contemporary society.

COMMON INQUIRIES

WHAT IS SILICON AND WHY IS IT IMPORTANT IN SOLAR PANELS?

Silicon, a widely available semiconductor, forms the core of most solar panels. It possesses exceptional properties that enable it to efficiently convert sunlight into electricity. The primary types of silicon utilized are monocrystalline and polycrystalline, which differ in manufacturing processes and efficiency levels. Monocrystalline silicon, derived from single crystal structures, tends to have higher efficiency rates but costs more. Polycrystalline silicon is less efficient but offers a more budget-friendly option. Silicon’s essential attributes, such as abundance and performance efficacy, make it invaluable in solar technology, allowing for greater advancements and sustainability in harnessing solar power.

HOW DO ANTI-REFLECTIVE COATINGS AFFECT SOLAR ENERGY GENERATION?

Anti-reflective coatings applied to the glass surface of solar panels significantly enhance energy absorption. By minimizing the reflection of sunlight, these coatings permit more light to penetrate the solar cells, directly impacting the panel’s overall efficiency. Without such coatings, a substantial amount of sunlight would be wasted, reducing the energy yield. Modern developments in anti-reflective technology continually aim to optimize the quantity of light captured, playing a vital role in the performance of solar energy systems. Consequently, the application of these coatings is considered a crucial aspect of solar panel design, directly correlated with overall energy generation capabilities.

WHAT OTHER MATERIALS ARE USED IN SOLAR PANEL MANUFACTURING?

In addition to silicon, various materials contribute to the effectiveness of solar panels. Aluminum frames provide structural support while ensuring lightweight characteristics, whereas copper wires facilitate efficient electrical connections. The use of glass protects the solar cells and enhances light transmission due to its tempered and anti-reflective properties. Polymers are crucial for encapsulation and insulation, safeguarding the components from environmental damage. By combining these various materials, solar panels are engineered to achieve both durability and optimal performance, ensuring that they meet the demands of modern energy requirements.

The integration of diverse materials into solar panel technology illustrates the complexity and sophistication of the system. Each ingredient fulfills a distinct role, contributing to the panel’s efficiency and longevity. With the world increasingly shifting towards sustainable energy solutions, understanding the significance of solar panel components becomes vital. Silicon remains the cornerstone, but the supporting materials enhance performance and durability, catering to varying residential and commercial energy needs. Furthermore, the ongoing research and advancements in material science promise even greater efficacy and performance optimization. As solar technology continues to evolve, the synergy between these ingredients will play a pivotal role in harnessing solar power, steering the course toward sustainable energy practices. By investing in and comprehending these components, society can advance toward a more environmentally friendly energy landscape, directly impacting future generations and their relationship with energy consumption.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-the-ingredients-of-solar-panels/