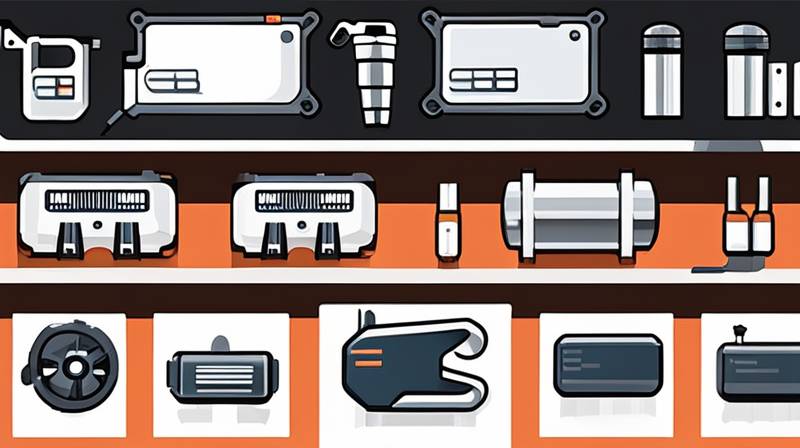

1. Energy storage welding guns comprise several essential components, including: 1. A capacitor bank that stores energy for discharge during welding, 2. A control circuit that regulates the electrical flow, 3. A trigger mechanism that initiates the welding process, 4. A housing that protects the internal components and provides safety during operation. The capacitor bank is particularly crucial as it enables the rapid release of energy in controlled bursts, allowing for effective and precise welding. This component’s ability to store substantial amounts of electrical energy briefly is vital for achieving the high temperatures required for welding materials together.

COMPONENTS OF ENERGY STORAGE WELDING GUNS

1. CAPACITOR BANK

The capacitor bank serves as the core of energy storage welding guns, acting as a reservoir for electrical energy. In technical terms, capacitors store electrical energy in an electric field, which can be released when an electrical circuit is closed. This feature offers significant advantages over traditional welding methods, such as transformer-based systems. The ability to store energy facilitates a rapid discharge, generating the necessary heat to fuse metals effectively.

Moreover, the size and arrangement of the capacitors play a pivotal role in determining the performance of the welding gun. A well-designed capacitor bank can deliver high currents in short bursts, allowing for precise and effective welding. The discharge must be sophisticatedly controlled to match the specifics of the materials being welded. The design of the capacitor bank also influences the overall efficiency and weight of the welding gun, making it a vital consideration in its engineering.

2. CONTROL CIRCUIT

A sophisticated control circuit governs the operation of the welding gun. This component regulates the electric flow between the capacitor bank and the welding tip, ensuring that the energy is released in a controlled manner. The control circuit can feature various electronic components, including resistors, diodes, and microcontrollers, which work together to achieve the desired output.

The effectiveness of a control circuit directly influences the quality of the weld. With advanced control systems, users can configure parameters like time, voltage, and current, tailoring the welding process to accommodate different materials and thicknesses. Additionally, safety features integrated into the control circuit can prevent overheating or electrical surges, providing a higher degree of reliability and efficiency in the welding operation.

3. TRIGGER MECHANISM

The trigger mechanism is a critical component of the welding gun, as it initiates the welding sequence. When activated, the trigger completes the circuit, allowing stored energy to flow from the capacitor bank to the welding tip. Consequently, this component significantly affects the user experience since a smooth trigger action can facilitate better precision during the welding process.

Different welding applications may require various types of trigger mechanisms, including mechanical switches and electronic triggers. The choice of trigger affects not only how easily a welder can start the process but also the consistency and quality of the weld. Moreover, incorporating safety features in the trigger design helps prevent accidental activation, enhancing user safety during operation.

4. HOUSING

The housing of an energy storage welding gun provides essential protection for its internal components and contributes to overall ergonomic design. Typically made from durable materials, the housing shields the delicate electronics and capacitor bank from external damage, dust, and moisture. Moreover, it ensures user safety by containing any potential electrical hazards.

The design of the housing can also impact the welding gun’s handiness and operator comfort. Factors such as weight distribution, grip design, and balance are all influenced by the housing. A well-engineered casing reduces fatigue during prolonged use, allowing welders to maintain optimal performance. Good housing design not only contributes to the tool’s longevity but also improves overall operational efficiency, thereby enhancing the welding experience.

5. WELDING TIP

The welding tip, also known as the electrode, is the component that directly interacts with the workpiece. It is where the electrical current is delivered, generating the heat necessary for melting materials. Weld tips come in various shapes and sizes, specifically designed for different welding applications, which can affect the weld’s characteristics.

Selecting the correct welding tip is paramount for achieving high-quality results. Factors such as tip size, material, and geometry influence the heat distribution and penetration, making it an essential consideration for welders. Additionally, understanding the thermal properties of the materials being welded will further allow for better performance, creating stronger bonds between materials.

6. HURDLES AND FUTURE TRENDS

Innovations in energy storage welding guns continue to evolve, yielding more efficient designs. However, manufacturers face challenges related to heat dissipation and component wear. As energy discharge happens rapidly, managing the thermal aspects can be crucial for maintaining tool longevity.

Future enhancements may include integrating smart sensors that provide real-time data on welding parameters. Recommendations for adaptive changes can also emerge from machine learning algorithms, optimizing practices based on feedback. Addressing hurdles like these will secure better quality welding in diverse industrial applications, ultimately fostering advancements that benefit the welding industry as a whole.

COMMON QUESTIONS ABOUT ENERGY STORAGE WELDING GUN COMPONENTS

WHAT IS THE IMPORTANCE OF THE CAPACITOR BANK?

The capacitor bank is the heart of the energy storage welding gun. Its capacity to store electrical energy and deliver it in rapid bursts is vital for effective welding. Capacitors enable a controlled release of energy, achieving the high temperatures required for melting metals together. The performance of the welding gun is heavily dependent on the design and efficiency of its capacitor bank, as this component directly influences weld speed, quality, and the range of materials that can be effectively joined.

Furthermore, advancements in capacitor technology are leading to more powerful and compact designs. High-capacity banks can significantly reduce welding times and improve precision across various applications. In analysis, a robust capacitor bank can enhance the overall reliability and operational efficiency of the welding gun, directly affecting the end user’s productivity.

HOW DOES THE CONTROL CIRCUIT AFFECT WELDING QUALITY?

The control circuit governs the entire operation of the welding gun, playing an essential role in determining the weld quality. A highly sophisticated control circuit can monitor and adjust parameters such as voltage, current, and discharge times in real-time to suit specific materials and thicknesses. These adjustments ensure that the energy released is optimized for the welding operation at hand.

Moreover, an effective control circuit includes safety features that minimize risks of overheating or electric surges. By maintaining a stable welding operation, it contributes to the formation of consistent weld seams with superior structural integrity. As technology advances, we expect even greater integration of smart features into control circuits, allowing for improved adaptability and performance during welding processes.

WHAT ROLE DOES THE HOUSING PLAY IN THE WELDING GUN?

The housing of an energy storage welding gun provides essential protection for all internal components while contributing to the tool’s ergonomics. Its primary function is to shield delicate electronics, capacitor banks, and wiring from environmental stressors such as dust, moisture, and impact hazards. High-quality housing materials enhance durability, ensuring that the tool can withstand rigorous working conditions often found in welding environments.

In terms of user interaction, the design of the housing is pivotal for comfort and usability. Ergonomics are meticulously considered, allowing for easier handling and reduced operator fatigue, particularly during extended use. A well-designed housing not only improves performance but safeguards against potential accidents, ultimately enhancing the overall welding experience.

The importance of understanding the components of energy storage welding guns cannot be overstated as it directly impacts performance, safety, and overall effectiveness in welding operations. Every individual component—from the capacitor bank to the housing and welding tip—plays a crucial role in ensuring that the welding process is efficient and reliable. Comprehending the function of each element equips users with the knowledge to make informed choices regarding their welding tools, thereby optimizing their processes and outcomes. Additionally, ongoing advancements and innovations in this field signify a commitment to enhancing performance and user safety, ensuring that energy storage welding guns remain at the forefront of modern welding technology. Engaging with these developments, welders can expect to improve their techniques, achieve higher quality welds, and benefit from enhanced operational convenience. Understanding and utilizing these components correctly will undoubtedly lead to improved efficiency and greater satisfaction across various welding applications. By staying informed about the latest trends and best practices in energy storage welding technology, users can maintain a competitive edge while continuing to deliver high-quality results.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-the-energy-storage-welding-gun-components/