Energy storage tray molds are essential components in the manufacturing of energy storage solutions, particularly in applications such as batteries and other energy-dense systems. 1. These molds create specific shapes and configurations for energy storage devices, 2. They significantly enhance the efficiency and scalability of production, 3. Their design must consider thermal management and material compatibility, 4. These molds are frequently subjected to rigorous quality control to ensure performance. Delving deeper into their functionality, these molds not only dictate the form factor but also influence the overall energy density and lifespan of the storage systems. The intricate design process behind these molds ensures that they can withstand various operational stresses while optimizing performance, ultimately contributing to advancements in energy storage technology.

1. UNDERSTANDING ENERGY STORAGE TRAY MOLDS

Energy storage tray molds play a pivotal role in the development and manufacturing of energy systems that require efficient storage solutions. These molds are specialized designs used to form various types of trays that hold energy storage technologies such as lithium-ion batteries, supercapacitors, and more. The molds allow for the creation of trays that support thermal management systems, enabling better performance and longevity of the energy storage devices housed within.

The function of these molds extends beyond simply shaping materials. They are engineered to accommodate specific requirements such as volume, weight, and material properties of the energy storage units. The correct mold ensures that the trays can support the battery or capacitor cells securely, while also allowing waste heat to dissipate efficiently. Moreover, the introduction of innovative materials and design approaches in energy storage tray molds has led to more advanced systems that prioritize sustainability alongside performance.

2. DESIGN ELEMENTS OF ENERGY STORAGE TRAY MOLDS

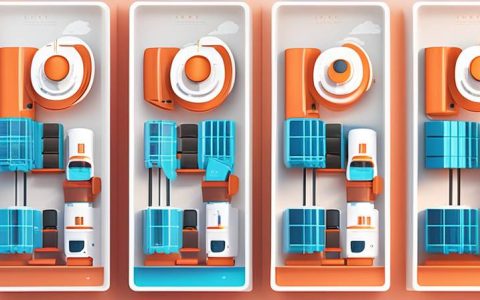

A key aspect of energy storage tray molds is their intricate design, which must take multiple factors into account. 1. Thermal regulation is a critical design factor, as excessive heat generated during operation can compromise the effectiveness and safety of energy storage solutions. Designers incorporate features such as channels or vents within molds to facilitate airflow, thereby managing temperatures more effectively. This attention to thermal dynamics is integral to enhancing the operational efficiency of the stored energy devices.

2. Material selection further complicates the design process. The molds can be made from various materials ranging from metals to advanced composites, depending on the desired characteristics of the final product. For instance, aluminum molds provide excellent thermal conductivity, while thermoplastics may offer cost-effective alternatives for lower production volumes. Regardless of material choice, the mold must maintain dimensional stability and withstand thermal cycling without significant degradation.

3. MANUFACTURING PROCESS OF ENERGY STORAGE TRAY MOLDS

The manufacturing of energy storage tray molds involves several sophisticated methods, each chosen based on the required mold characteristics and production volume. 1. Injection molding is a popular technique, particularly for large production runs where consistency and speed are paramount. This method allows molten material to be injected into a mold cavity, where it cools and hardens into the desired shape. The precision offered by injection molding leads to high-quality molds, enabling reliable energy storage devices.

Another prevalent technique is 3D printing, which provides flexibility in design and rapid prototyping of molds. This additive manufacturing method allows for intricate geometries that might be challenging to achieve via traditional methods. Innovations in 3D printing technology can result in designs that enhance both performance and thermal management of the energy storage trays. The ability to quickly iterate on designs has accelerated the pace of mold development, driving advancements in energy storage technology.

4. QUALITY CONTROL AND TESTING OF ENERGY STORAGE TRAY MOLDS

The significance of rigorous quality control in the production of energy storage tray molds cannot be overstated. 1. Testing methods involve both dimensional analysis and functional assessments to ensure that molds meet specified criteria before they are used in production. These tests verify that the molds will produce trays with the required tolerances and performance metrics, safeguarding against potential failures in the energy storage devices they produce.

Moreover, 2. lifecycle assessments are conducted to evaluate how the molds perform under operational conditions. Understanding how materials age under thermal stress and in various chemical environments ensures long-term reliability of the molds. Periodic inspections and evaluations contribute to continuous improvements, not only enhancing the molds themselves but also benefiting the end products they create.

5. INNOVATIONS IN ENERGY STORAGE TRAY MOLDS

As the demand for energy storage solutions evolves, so does the technology behind tray molds. 1. Recent innovations have focused on microstructural manipulation of mold materials to improve thermal conductivity and mechanical properties. By altering the microscopic structure of materials used in molds, manufacturers can achieve improved heat dissipation and enhanced energy retention capabilities of storage devices.

2. Incorporation of smart technologies into mold design presents exciting opportunities for monitoring and optimization during production. Equipment outfitted with sensors can provide real-time data on temperature, pressure, and overall production dynamics. Such feedback can allow for adjustments during the molding process, leading to higher quality products and reduced waste.

6. APPLICATIONS OF ENERGY STORAGE TRAY MOLDS

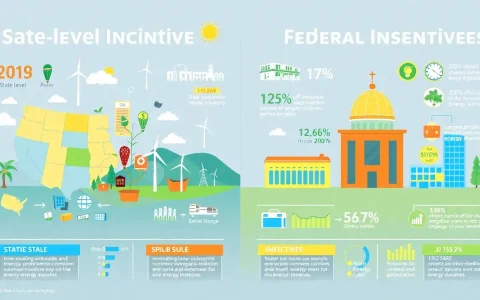

The application of energy storage tray molds spans various industries, each with its unique requirements and challenges. 1. The automotive sector, particularly with the rise of electric vehicles, relies heavily on advanced energy storage systems, and thus requires specialized molds for producing high-capacity battery trays that can withstand vibrations and temperature fluctuations involved in daily vehicle operation.

2. Renewable energy sectors, such as solar and wind, also utilize these molds for energy storage systems designed to store excess energy generated during peak production times for use during periods of low generation. The adaptability of energy storage tray molds makes them suitable for various types of systems, enhancing their utility across diverse technological applications.

FREQUENTLY ASKED QUESTIONS

WHAT IS THE IMPORTANCE OF ENERGY STORAGE TRAY MOLDS?

The significance of energy storage tray molds lies in their ability to shape and define the form factor of various energy storage devices, ensuring efficient thermal management and structural integrity. These molds facilitate scaling up production, allowing manufacturers to produce high volumes of energy storage solutions that meet evolving energy demands. Additionally, their design must be adaptable, keeping pace with rapid advancements in energy technology, making them crucial for the future of sustainable energy.

HOW DO DESIGN FACTORS INFLUENCE ENERGY STORAGE TRAY MOLDS?

Design factors significantly impact the functionality and effectiveness of energy storage tray molds. Thermal management, for instance, is a primary design aspect; it ensures that excessive heat does not degrade the performance of energy storage devices. Moreover, the selection of materials affects durability and cost-effectiveness. Designs must also accommodate variations in production methods, as different techniques may require specific mold configurations. Collectively, these design factors are paramount in creating reliable energy storage solutions.

WHAT ROLE DOES QUALITY CONTROL PLAY IN THE MANUFACTURING OF ENERGY STORAGE TRAY MOLDS?

Quality control is a fundamental aspect of the manufacturing process for energy storage tray molds. It involves precise testing and evaluation of mold integrity, dimensions, and functionality, ensuring that every mold produced meets rigorous standards. Such assessments are essential to preventing issues that may arise during the production of energy storage devices, which could lead to failures in performance or safety. Continuous quality assurance processes help maintain high standards, thereby supporting the reliability and longevity of energy storage technologies.

The relevance of energy storage tray molds cannot be underestimated as they are foundational to the development of modern energy storage solutions. These molds serve a dual purpose: first, they shape the physical form of energy storage devices, providing the necessary structural framework for battery systems and capacitors; second, their design intricacies contribute to the overall efficiency and reliability of the energy storage systems. By optimizing heat dissipation and material compatibility, these molds ensure sustained performance and longevity of the devices they produce. The manufacturing processes employed to create these molds, such as injection molding or additive manufacturing, reflect the need for precision and adaptability to meet evolving technological demands. Furthermore, the rigorous quality control measures implemented throughout production safeguard against potential failures in the energy storage devices, ensuring seamless operation over time. Innovations within this field continue to drive advancements not solely in the molds themselves but also in the energy storage technologies they create. As industries evolve, and the demand for efficient energy storage solutions grows, the significance of energy storage tray molds will undoubtedly expand, solidifying their role within the wider context of energy management and sustainability.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-the-energy-storage-tray-molds/