Energy storage battery casing fixtures are integral components of battery systems, serving several critical purposes. 1. These fixtures provide structural integrity, ensuring that the batteries remain secure during operation and transportation. 2. They facilitate thermal management, allowing for efficient heat dissipation that is essential for maintaining optimal performance and longevity of the batteries. 3. They contribute to safety, serving as a protective barrier against environmental factors and potential impacts. 4. Modular designs in these fixtures enable easy scalable solutions, allowing manufacturers to adapt to various battery sizes and configurations. Elaborating on safety, it is essential to highlight that robust casing fixtures prevent leakage of hazardous materials and mitigate the risk of thermal runaway, showcasing their fundamental role in protecting both equipment and users from potential hazards.

1. UNDERSTANDING ENERGY STORAGE SYSTEMS

Energy storage systems (ESS) have gained substantial attention due to the increasing demand for sustainable energy solutions. These systems incorporate various technologies to store energy for later use, with battery systems being among the most prevalent due to their versatile applications ranging from electric vehicles to renewable energy integration. The significance of battery casing fixtures cannot be overstated, as they play a pivotal role in the overall effectiveness and reliability of these systems.

Battery systems must endure various environmental conditions, and this is where casing fixtures become paramount. A well-designed fixture offers mechanical robustness, which ensures that the battery cells are held firmly in place. The mechanical integrity afforded by these fixtures is essential for preventing damage during transport and operation. In areas where temperature fluctuations are common, such structural support helps maintain battery performance and extends service life.

2. MATERIALS AND DESIGNS FOR CASING FIXTURES

The materials used for battery casing fixtures significantly impact their performance and longevity. Manufacturers often opt for high-strength materials, such as reinforced polymers and aluminum alloys, that exhibit durability while remaining lightweight. The choice of material dictates the thermal and mechanical properties of the fixture, influencing factors such as heat dissipation and resistance to corrosion, which is especially crucial for battery systems exposed to various environmental conditions.

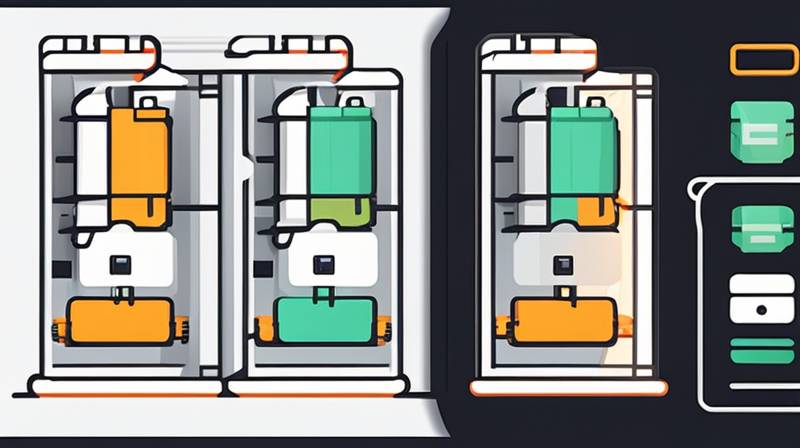

Design approaches also vary widely, with efficiency being a primary concern. Modular designs allow for flexibility, enabling manufacturers to customize fixtures tailored to specific battery sizes and configurations. This adaptability ensures that production can be streamlined without compromising individual battery safety and efficiency requirements.

Incorporating specialized features, such as integrated cooling channels or vibration dampening mechanisms, can enhance the functionality of casing fixtures. These considerations ensure that energy storage systems remain within operational parameters regarding temperature and vibration, thereby reducing the risk of system failure.

3. THERMAL MANAGEMENT IN BATTERY SYSTEMS

Effective thermal management is crucial for maximizing the performance and lifespan of battery systems. As batteries charge and discharge, they generate heat; therefore, energy storage designs must account for this thermal output. Casing fixtures contribute by facilitating adequate air circulation and dispersing heat efficiently.

Advanced thermal management solutions may involve the integration of heat sinks or cooling fans within the casing. This approach allows excess heat to be dissipated quickly, thus maintaining an optimal operating temperature. As battery performance is directly linked to temperature, maintaining homeostasis is essential for ensuring both efficiency and safety.

Fluctuating temperatures present a challenge as high temperatures can lead to degradation, while excessively low temperatures can hinder performance. Battery casing fixtures designed with thermal insulation properties can mitigate these extremes, providing a controlled environment that fosters consistent energy output.

4. SAFETY CONSIDERATIONS FOR BATTERY CASING FIXTURES

Safety remains the top priority in any design concerning energy storage battery systems. Casing fixtures serve to protect against physical impacts, preventing penetration that could lead to catastrophic failures, such as fire or explosion. This protective barrier is essential in keeping hazardous materials contained within the battery.

Moreover, effective sealing mechanisms prevent moisture ingress and the accumulation of contaminants. Exposure to moisture can lead to degradation of battery components or electrolyte leaks, which not only compromise performance but also pose significant safety risks.

Designers must also consider the potential for thermal runaway. Appropriate fixture designs can aid in heat dispersion, reducing the likelihood of rapid temperature increases that characterize this dangerous phenomenon. Implementing robust warning systems for thermal anomalies ensures that appropriate actions can be taken before critical thresholds are reached, thereby enhancing overall safety.

5. REGULATIONS AND STANDARDS FOR ENERGY STORAGE

Regulatory compliance is integral to the design and manufacturing of energy storage battery casing fixtures. Various international and national standards govern safety and performance criteria that these fixtures must meet. Adhering to standards ensures that products are safe and effective, providing customers with confidence in their reliability.

These regulations often cover material safety, electromagnetic compatibility, and environmental impacts. Manufacturers must stay abreast of changes in legislation, as these standards evolve with advances in technology and ongoing research. For example, compliance with UL (Underwriters Laboratories) standards can signal to the user that the battery system can withstand rigorous testing for safety.

Additionally, understanding local regulations helps manufacturers ensure that products are suitable for varied markets. This knowledge fosters innovation, as design modifications may be necessary to fulfill specific regional demands, ultimately leading to better product performance.

6. FUTURE TRENDS IN ENERGY STORAGE BATTERY FIXTURES

As technology advances, the landscape of energy storage continues to evolve, prompting innovative approaches to battery casing fixtures. Emerging trends focus heavily on enhancing efficiency and sustainability, both in terms of materials used and the overall lifecycle impact of these fixtures.

Recyclable materials and eco-friendly manufacturing processes are becoming increasingly important. Consumers now prioritize sustainability, prompting manufacturers to explore biodegradable alternatives and processes that minimize waste. Incorporating intelligent technologies, such as IoT-enabled sensors within fixtures, allows for real-time monitoring of battery health and performance metrics.

Research and development in nanotechnology also hold promise for the future, allowing for the creation of lightweight yet durable casing solutions with improved thermal characteristics. These advancements could lead to energy storage systems that are not only safer but also more adaptable to various applications, which is essential as the world transitions toward renewable energy sources.

7. COST IMPLICATIONS OF ENERGY STORAGE FIXTURES

The expense associated with manufacturing and implementing effective battery casing fixtures can significantly influence the overall cost of energy storage systems. Investing in high-quality materials and advanced design features can elevate initial expenditures but may offer long-term benefits through enhanced reliability and reduced maintenance needs.

The balance between cost and performance requires careful consideration, as overspending on overly complex designs may not yield proportional benefits. Conversely, opting for the bare minimum in terms of quality can expose systems to unnecessary risks, leading to costly failures.

Market trends reflect a growing expectation for price reductions as competition increases. The integration of optimized manufacturing techniques, such as 3D printing, can reduce costs associated with complex designs while allowing for enhanced customization.

8. MAINTENANCE AND REPAIR OF BATTERY CASING FIXTURES

Ongoing maintenance is crucial for preserving the integrity and functionality of battery casing fixtures over time. Regular inspections enable the early detection of potential issues, such as material wear or structural damage resulting from thermal cycles or physical impacts.

Implementing a proactive maintenance schedule fosters confidence in performance, ensuring that energy storage systems operate efficiently. Should repairs be necessary, employing the right techniques is vital. For instance, replacing components or applying specialized coatings can restore functionality without necessitating the complete replacement of the fixture.

It is essential for users to follow manufacturer guidelines on maintenance to uphold safety standards. Inadequately maintained fixtures not only jeopardize efficiency but could also increase the risk of failures, underscoring the importance of diligent upkeep in extending the lifespan of energy storage systems.

QUESTIONS AND ANSWERS

WHAT ARE THE PRIMARY FUNCTIONS OF BATTERY CASING FIXTURES?

Battery casing fixtures serve multiple crucial roles in energy storage systems. Primarily, they provide structural integrity, ensuring that battery cells remain secure during both operation and transportation. This stability is vital as movement or vibration can lead to misalignment, which can reduce the efficiency of the battery. Secondly, these fixtures aid in thermal management, allowing for the efficient dissipation of heat generated during the charge and discharge cycles of the battery. When battery temperatures are within optimal ranges, their performance and lifespan substantially improve. Moreover, battery casing fixtures enhance safety by acting as barriers against physical impacts, leaks, and exposure to environmental factors. For instance, a well-designed fixture prevents hazardous materials from escaping the battery and protects the internal components from external damage. In summary, battery casing fixtures are indispensable for delivering reliability, performance, and safety, all of which are critical for user confidence in energy storage systems.

HOW DO CASING FIXTURES IMPROVE THE PERFORMANCE OF BATTERY SYSTEMS?

The performance of battery systems is significantly influenced by the quality of their casing fixtures. Effective thermal management is one of the key enhancements provided by well-designed fixtures. By ensuring that batteries maintain appropriate temperature levels, fixtures prevent thermal degradation and energy losses. When battery systems operate within their optimal thermal range, they deliver higher efficiency and faster charging times. Furthermore, casing fixtures improve the mechanical stability of batteries. This stability is crucial during transportation and usage, as it minimizes vibrations and impacts that could dislodge critical components, consequently enhancing overall performance and reliability. Additionally, the modular designs often integrated into casing fixtures allow for customization to suit different battery types, leading to improved performance in specialized applications. Such adaptability ensures better compatibility with various energy storage needs, making the system more efficient. To summarize, through thermal management, mechanical stability, and adaptability, casing fixtures contribute profoundly to the performance of energy storage battery systems, ensuring lasting efficiency and effectiveness.

WHAT FACTORS SHOULD BE CONSIDERED IN SELECTING BATTERY CASING FIXTURES?

Choosing the right battery casing fixtures involves evaluating various factors to ensure optimal performance and safety. Material selection is critical, as it affects durability, weight, and thermal properties. High-strength materials such as aluminum or thermoplastics can offer exceptional performance while minimizing weight, which is crucial for applications in mobile batteries. Furthermore, understanding the environmental conditions the battery systems will be subjected to plays a vital role in ensuring longevity. Casing fixtures must be capable of withstanding temperature variations, moisture, and potential corrosive elements. Thermal management capabilities, such as integrated cooling features or airflow optimization, are also essential for maintaining the operational efficiency of batteries. Moreover, evaluating the cost vs. performance ratio assists in identifying fixtures that deliver the required specifications without inflating overall expenses. Ultimately, selecting battery casing fixtures should consider material, environmental factors, thermal management, and cost to ensure safe and efficient battery operations across varied applications.

The design and function of energy storage battery casing fixtures are crucial in ensuring the effectiveness, safety, and longevity of battery systems. Careful consideration of materials, structural integrity, thermal management, and regulatory compliance is essential in manufacturing and choosing these fixtures. The future of energy storage solutions will undoubtedly see innovations in materials and technologies, enhancing the adaptability and efficiency of battery systems. Continuous research and development efforts will drive improvements, supporting the shift toward sustainable energy practices globally. As the demand for improved energy storage solutions rises, manufacturers must prioritize safety and performance without compromising on quality. Furthermore, ongoing maintenance is vital for ensuring that these fixtures deliver optimal performance throughout their lifecycle. Users must remain informed and proactive in their approach to handling, maintaining, and understanding the significance of these crucial components in energy storage systems.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-the-energy-storage-battery-casing-fixtures/