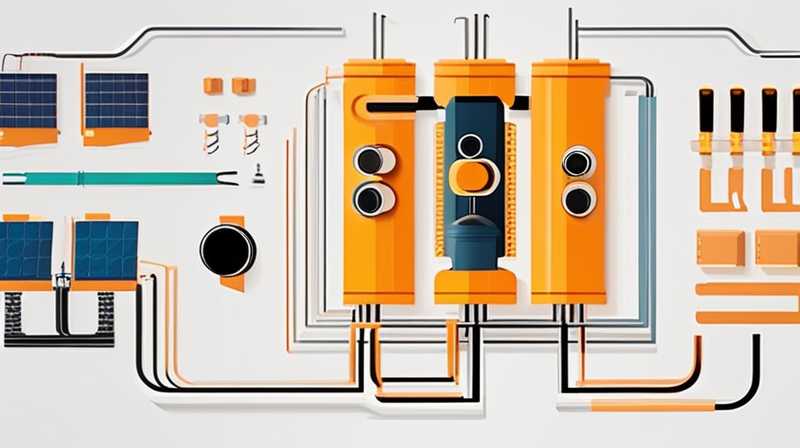

The components of a solar solenoid valve generally include 1. electromechanical actuator, 2. valve body, 3. diaphragm, 4. spring, 5. inlet and outlet ports, 6. electrical terminal connections. The electromechanical actuator serves the critical role of converting electrical energy into mechanical motion to open or close the valve. The valve body holds together the various components and typically consists of robust materials to withstand environmental stresses. The diaphragm separates the hydraulic fluid from the actuator and provides a sealing function, maintaining system integrity. A spring is employed to reset the diaphragm to its closed position when not in use. Inlet and outlet ports direct the fluid flow in and out of the valve, while electrical terminal connections facilitate the flow of current from the solar panel to the actuator. Each element synergistically works to ensure the efficient operation of a solar-powered irrigation or fluid management system, making understanding these components essential for effective solar solution implementation.

1. ELECTROMECHANICAL ACTUATOR

The electromechanical actuator is arguably the heart of the solar solenoid valve. In its operation, it converts electric power from solar energy into mechanical motion, allowing for the precise manipulation of the valve’s position. This actuator works by using a coil of wire, known as an electromagnetic coil, which generates a magnetic field when electricity flows through it. This magnetic field causes a movable metal rod to either move upward or downward, triggering the valve to open or close.

One of the significant advantages of electromechanical actuators is their responsiveness. When integrated into a solar energy system, they provide quick adjustments to fluid passage based on solar panel output, promoting efficient usage of water, particularly in agricultural applications or irrigation systems. Moreover, their ability to operate on low voltage makes them particularly suitable for off-grid applications, aligning perfectly with sustainable practices, minimizing energy consumption and promoting environmental harmony. The mechanical movement generated by the actuator is highly reliable, ensuring long-term performance without frequent maintenance interventions.

2. VALVE BODY

The valve body is the structural framework that houses all the components of the solenoid valve. Typically crafted from durable materials such as brass, stainless steel, or plastic, the body is designed to withstand high pressures and corrosive environments. The choice of material is crucial because it directly impacts the valve’s lifespan and reliability. For instance, brass is often chosen for its excellent mechanical properties and resistance to corrosion, while plastic might be utilized in applications with less demanding conditions.

In addition to its protective function, the valve body plays a pivotal role in maintaining fluid integrity. It features precisely machined passages that enable fluid to flow in a specific manner. Design intricacies, such as inlet and outlet port sizes, can particularly affect flow rates, making it vital for engineers to meticulously consider these parameters during valve selection. By ensuring that the valve body is well designed, manufacturers help guarantee efficient operation, significantly reducing the likelihood of leaks or failures that could disrupt system functionality.

3. DIAPHRAGM

The diaphragm is a critical component that acts as a seal and a dynamic element in the operation of solenoid valves. Typically made from elastomeric materials, the diaphragm is flexible and can deform to create a tight seal when the valve is closed. This sealing capability is essential for ensuring no fluid escapes the system when the valve is not in operation. The diaphragm also provides an immediate response to the actuator’s movements, facilitating swift opening and closing actions.

The material choice for the diaphragm impacts both performance and longevity. Materials like silicone, rubber, or thermoplastic elastomers are often used, each selected based on the specific fluid type and operational conditions. For instance, silicone might be preferred for its flexibility and resistance to temperature fluctuations, while rubber could offer better resistance against specific chemicals. By choosing the appropriate diaphragm material, users can significantly enhance the valve’s reliability and overall performance, ensuring optimal operation in various circumstances.

4. SPRING

The spring in a solar solenoid valve fulfills a crucial function by maintaining the valve’s position when not activated. Typically, springs are used to reset the diaphragm to a closed position once the electric current is removed from the actuator. This automatic return mechanism is important for ensuring that fluid does not flow unintentionally, which could lead to wastage or operational problems in an irrigation system.

The design of the spring, including its stiffness and material, directly influences the valve’s responsiveness. A spring that is too stiff may lead to sluggish performance, while one that is too weak could fail to keep the valve sealed properly. It’s essential to strike a balance in spring design, which requires careful engineering and testing to ensure that the valve performs optimally under various conditions. This aspect of valve design is vital, particularly in applications where the constant flow of fluid is necessary at all times—the spring must be able to cope with these demands while continuing to perform reliably over time.

5. INLET AND OUTLET PORTS

The inlet and outlet ports are crucial interfaces for the flow of fluids in and out of the solenoid valve. Typically designed with specific diameters and thread sizes, these ports must match the connecting pipes or hoses to guarantee a secure fit and avoid leaks. Proper sizing of the ports helps optimize the fluid dynamics, influencing flow rates and pressure conditions within the system.

In practical applications, the configuration of these ports can greatly determine the effectiveness of the valve. For example, larger ports may facilitate higher flow rates but could also increase turbulence, which might impact the performance of the downstream system. Conversely, smaller ports can maintain a steady flow but may be inadequate for high-demand applications. Designers must carefully evaluate the application’s requirements and system limitations to choose the appropriate inlet and outlet port configurations, thereby ensuring seamless integration and efficient fluid management.

6. ELECTRICAL TERMINAL CONNECTIONS

Electrical terminal connections provide a means for powering the solenoid valve via the solar energy system. The integrity of these connections is paramount, as they ensure a reliable electrical flow to the actuator. Typically, these connections are designed for easy installation and removal, often featuring connectors that secure snugly to prevent disconnections during operation.

Additionally, environmental considerations also play a role in the design of these connections. They need to be resistant to moisture, dirt, and other contaminants that could compromise their function. Proper insulation and protective coatings are commonly employed to enhance durability. Furthermore, the gauge of the wiring used in these connections is critical; incorrectly sized wiring can lead to inefficiency or even shorts in the system. Ensuring that these electrical terminal connections are robust and reliable contributes significantly to the overall performance of the solar solenoid valve.

7. ADDITIONAL COMPONENTS

While the primary components have been discussed, other supplementary elements may enhance the overall functionality of a solar solenoid valve. For instance, protection circuitry may be integrated to prevent damage from voltage spikes or surges, ensuring the longevity of the actuator. This additional layer of protection helps maintain system integrity, particularly in dynamic solar energy environments where fluctuations in output can be common.

Incorporating such protective features not only enhances the valve’s reliability but also promotes sustainability, since fewer replacements and repairs contribute to reduced waste and lower resource use over time. Furthermore, incorporating smart technologies could allow for remote monitoring and programming of the valve’s operation, enhancing operational efficiency and adaptability. These advancements can be particularly useful in large-scale agricultural settings, permitting farmers to optimize irrigation based on real-time environmental data, thereby significantly improving resource management.

8. MAINTENANCE CONSIDERATIONS

To achieve optimal performance from a solar solenoid valve, regular maintenance is necessary. Routine checks should be carried out to ensure that all components are functioning as intended, with particular attention paid to the diaphragm and valve body for any signs of wear or damage. Performing these checks not only extends the life of the valve but also aids in avoiding unexpected system failures, which could lead to costly downtime.

Moreover, keeping the electrical terminal connections clean and secure will prevent operational issues caused by poor conductivity. Regular inspections of the entire system help identify potential problems before they escalate, allowing for timely interventions. By ensuring diligent maintenance practices, users can achieve greater efficiency and reliability from their solar solutions, ultimately maximizing the benefits derived from renewable energy investments.

9. IMPACT ON ENVIRONMENTAL SUSTAINABILITY

Solar solenoid valves are instrumental in promoting environmental sustainability. Their integration into irrigation systems reduces water wastage by ensuring precise control over fluid flow, which is critical as societies grapple with increasing freshwater scarcity due to climate change and urbanization.

Additionally, using solar power to operate these valves eliminates reliance on fossil fuels, thus significantly lowering greenhouse gas emissions. Every integration of a solar solenoid valve helps create ecosystems that work in harmony with the environment, promoting responsible resource management. This alignment with sustainable practices not only enhances agricultural yields but also contributes positively to local ecosystems, ensuring that future generations inherit a balanced and thriving planet.

FAQs

WHAT IS A SOLENOID VALVE?

A solenoid valve is an electromechanical device used to control the flow of fluids or gases in a system. These valves operate through the use of an electromagnetic coil that, when energized, generates a magnetic field, enabling the valve to open or close based on electrical signals. Solenoid valves are commonly employed in various applications, including irrigation systems, automotive engines, and HVAC units, due to their ability to provide rapid and reliable control of fluid flow.

HOW DOES A SOLAR SOLENOID VALVE WORK?

A solar solenoid valve operates by utilizing energy from solar panels to power its electromechanical actuator. When the solar panel generates sufficient power, electrical current flows to the actuator, creating a magnetic field that causes the valve to open or close. The efficient use of solar energy allows for self-sufficient operation, making these valves ideal for applications where traditional power sources are unavailable or impractical, such as remote irrigation systems or off-grid settings, thereby promoting sustainable resource management.

WHAT ARE THE ADVANTAGES OF USING SOLAR SOLENOID VALVES?

Solar solenoid valves offer numerous advantages, including energy efficiency, remote operation capabilities, and reduced reliance on fossil fuels. By utilizing solar power, these valves minimize energy costs and provide a sustainable solution for various fluid management applications, particularly in regions with abundant sunlight. Additionally, their timely responsiveness to electrical signals enables precise control over fluid flow, promoting optimal resource use and reducing waste. Engaging solar solenoid valves in agricultural practices can lead to enhanced productivity while minimizing environmental impacts, making them integral to modern sustainable practices.

Devices designed to manage fluid flow in sustainability-driven applications hinge on the unique operations of solar solenoid valves, exhibiting various vital components that warrant attention. Each part, from the actuator to duct connectors, contributes critically to overall efficiency, durability, and responsiveness under diverse environmental conditions. Understanding these elements is instrumental in optimizing systems for effective operation and longevity. The momentum toward eco-friendly practices necessitates grasping how these components interact harmoniously, especially since the global community is increasingly recognizing the pressing need to embrace sustainability across all domains of life.

Investments in these technologies not only showcase a commitment to ecological responsibility but also yield economic advantages through decreased operational costs and resource efficiency. Addressing water scarcity or energy shortages with innovative solutions via solar solenoid valves clearly highlights the intersections of practicality and environmental stewardship. As the solar industry continues to evolve, the role of such devices will be pivotal in formulating resilient infrastructures designed for efficacy, adaptability, and sustainability.

Thus, grasping the intricate components of the solar solenoid valve is more than just a technical pursuit; it paves the way toward a more sustainable future that encapsulates both ecological and economic considerations. As advancements increase, there lies an opportunity for enhanced performance, leading to further innovation in how industries manage their fluid dynamics reliant on renewable energy sources.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-the-components-of-solar-solenoid-valve/