1. POLYCRYSTALLINE SOLAR PANELS ARE COMPOSED OF SILICON CRYSTALS, METAL CONDUCTORS, AND GLASS. The crystalline structures in these panels are formed from multiple silicon crystals that enhance efficiency while facilitating mass production. 2. EACH COMPONENT PLAYS A CRUCIAL ROLE IN CAPTURING SOLAR ENERGY AND CONVERTING IT INTO ELECTRICITY. Understanding the individual roles of these components, as well as their interactions, is vital for comprehending how polycrystalline solar panels work effectively in various applications. 3. THE GLASS PROVIDES PROTECTION TO THE MODULE AND ALLOWS LIGHT TO PASS THROUGH, GUARANTEEING OPTIMAL ABSORPTION. Thus, the interplay among these elements maximizes performance and longevity, making polycrystalline solar panels a reliable and sustainable energy solution.

1. COMPONENTS OF POLYCRYSTALLINE SOLAR PANELS

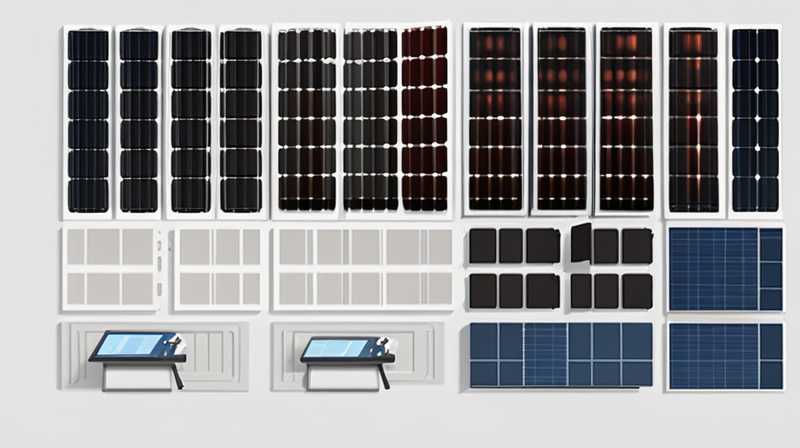

Solar energy technology has gained considerable traction as a viable renewable energy source. Among the various solar panel types, polycrystalline solar panels have become popular due to their efficiency and cost-effectiveness. These panels are constructed using multiple silicon crystals fused together during manufacturing. The key components can be categorized into four primary elements: solar cells, encapsulant, backsheet, and frame. Unpacking these components reveals their intricate roles in the functionality and performance of solar panels.

SOLAR CELLS

The heart of polycrystalline solar panels lies within the solar cells, which are primarily made of silicon. These silicon cells are composed of many small silicon crystals. The unique arrangement of these crystals creates a structure that allows for effective light absorption and energy conversion. When sunlight hits the surface of the silicon cells, electrons are knocked loose from their atoms, creating an electric current.

The effectiveness of energy conversion is influenced by factors like the purity of silicon used and the manufacturing process of the cells. Higher purity silicon allows for improved electron movement, enhancing overall efficiency. Moreover, the thickness of the silicon layer can also affect the light absorption ability; too thin may not capture enough light, while too thick can impede electron mobility.

ENCAPSULANT

Surrounding the solar cells is the encapsulant, a layer usually made of ethylene-vinyl acetate (EVA). This component plays a vital role in protecting the solar cells from environmental factors such as moisture, dirt, and mechanical damages. Beyond protection, the encapsulant acts as a glue that holds the solar cells in place within the panel structure.

The main function of the encapsulant is to ensure the longevity of the solar cells by preventing any physical or chemical damage that could occur. It also provides optical benefits, allowing maximum sunlight to penetrate the surface of the solar cells. A high-quality encapsulant can significantly extend the operational life of polycrystalline solar panels, often exceeding 25 years under optimal conditions.

BACKSHEET

Another important component is the backsheet, usually made from polymer materials like PVDF (Polyvinylidene fluoride) or Tedlar. The backsheet provides insulation and protection from external elements. This component is crucial for the durability and reliability of polycrystalline panels, especially considering they are often exposed to harsh weather conditions.

The backsheet also functions as a protective barrier that prevents moisture ingress, which could lead to deterioration or failure of the solar cells. A robust and high-quality backsheet can reduce the risk of catastrophic failures over time, thereby ensuring that the panel maintains its efficiency throughout its operational life. Additionally, it contributes to the overall structural integrity of the solar panel system.

FRAME

The outer frame, typically made of aluminum, serves as the structural foundation of polycrystalline solar panels. This frame provides support and stability, ensuring the panels remain intact during severe weather events such as heavy winds or hailstorms. More than just a protective barrier, the frame aids in the installation process by allowing for easy mounting onto rooftops or ground structures.

In terms of insulation, the frame ensures that the edges of the solar cells are secure, reducing the likelihood of mechanical wear and potential damages over time. Moreover, an aluminum frame can also help dissipate heat generated during the solar conversion process, improving the overall efficiency of the panels. Thus, both support and performance are enhanced by the presence of a dedicated frame.

2. WORKING MECHANISM OF POLYCRYSTALLINE SOLAR PANELS

The interaction between the components plays a vital role in the overall performance of polycrystalline solar panels. Understanding how these parts work in concert can demystify the power generation process and highlight the potential benefits of solar energy. The conversion of solar energy into usable electricity involves a series of sophisticated processes.

PHOTOVOLTAIC EFFECT

The fundamental principle governing the operation of polycrystalline solar panels is the solar photovoltaic effect. When photons from sunlight strike the solar cells, they energize the silicon electrons, allowing them to break free from their atoms. This movement generates electron-hole pairs, resulting in a direct current (DC). The efficiency of this process heavily relies on the quality of the silicon crystals used and the connection between them.

Once the electrons become mobile, they travel through the silicon lattice and are directed towards conductive metal plates. These plates serve as pathways for the electrons to flow out of the solar cell and into an external circuit. The design and orientation of these metal contacts are essential, significantly affecting the overall electrical output of the solar panel. Optimization of these components can lead to greater energy efficiency and higher yields.

ELECTRICITY GENERATION

Once the DC is generated within the panels, it often needs to be converted to alternating current (AC) for most household and commercial applications. This conversion occurs through a device called an inverter. The inverter plays a crucial role in enabling the energy generated by the polycrystalline solar panels to be compatible with the electrical grid.

In some solar installations, the setup may include energy storage systems, such as batteries. Energy storage allows for utilizing solar power during night-time or cloudy days when sunlight is not readily available. Therefore, integrating storage solutions can make solar energy more reliable and usable, enhancing the overall appeal of polycrystalline solar technology.

3. COST AND EFFICIENCY OF POLYCRYSTALLINE SOLAR PANELS

One of the compelling reasons behind the widespread adoption of polycrystalline solar panels is their cost-effectiveness compared to other types of solar panels. While they may not provide the absolute highest efficiency rates, their balance of affordability and performance has made them a favored choice among both residential and commercial users.

MANUFACTURING COSTS

The manufacturing processes of polycrystalline solar panels are relatively straightforward, primarily because they utilize silicon that is melted and crystallized in a less complex manner than monocrystalline panels. This simplicity translates to lower production costs, which can then be reflected in the end price for consumers. Bulk production techniques in the panel industry also contribute to reduced costs.

Though they often occupy more space compared to monocrystalline panels, polycrystalline panels can still deliver competitive efficiencies, making them a viable choice for various installations. As technology improves and manufacturing processes become more refined, the affordability factor is likely to improve even further, making solar energy more accessible for the average consumer.

EFFICIENCY RATINGS

Polycrystalline solar panels typically have efficiency ratings ranging from 15% to 22%. These ratings signify the percentage of sunlight that can be converted into usable electricity under standardized testing conditions. While they are generally less efficient than monocrystalline alternatives, their performance can stabilize in high-heat conditions where some other technologies falter.

Additionally, advancements in technology and material science have continuously pushed polycrystalline panels’ efficiency ratings upward, closing the performance gap with their counterparts. Moreover, the gradual decline in prices makes them a practical choice for those seeking sustainable energy solutions without breaking the bank. The trade-off between slightly lower efficiency and striking cost advantages makes polycrystalline panels an attractive option overall.

4. ENVIRONMENTAL IMPACT AND SUSTAINABILITY OF POLYCRYSTALLINE PANELS

In the current climate affecting our planet, the environmental footprint of energy generation technology becomes critical. Polycrystalline solar panels generally have a lower carbon footprint in terms of energy production compared to fossil fuels. The process of manufacturing these panels does have an environmental impact, yet ongoing research continuously aims to improve these processes, minimizing waste and energy consumption.

LIFE CYCLE IMPACT

When assessing the carbon footprint of polycrystalline solar panels, it is essential to consider their entire life cycle. The life cycle of solar panels consists of various stages, including raw material extraction, manufacturing, installation, and decommissioning. While the energy consumed during production can be substantial, once installed, these panels can produce clean energy over their long operational lives, often exceeding 25 years.

Research indicates that the energy payback time for polycrystalline solar panels can range from 1 to 4 years, depending on the technology used and installation conditions. This means that after this payback period, the panels contribute clean energy for an extended duration, leading to a net positive impact on the environment. As such, the overall life cycle analysis leans in favor of polycrystalline solar technology as a sustainable energy solution.

RECYCLABILITY

A further aspect of environmental considerations lies in the recyclability of polycrystalline solar panels. As the solar industry matures, companies are becoming increasingly aware of potential waste issues associated with decommissioned solar panels. Infrastructure is being developed to recycle and repurpose materials from these units to mitigate the ecological impact.

Silicon, metals, and other materials can often be recovered, reused, and repurposed, which reduces the need for new raw materials. Investments into recycling technologies can further enhance the sustainability of solar technologies, ensuring that both the environmental and economic implications are thoroughly considered. Thus, ongoing innovation will likely bolster the lifecycle sustainability credentials of polycrystalline solar panels.

FREQUENTLY ASKED QUESTIONS

WHAT IS THE AVERAGE LIFESPAN OF POLYCRYSTALLINE SOLAR PANELS?

The average lifespan of polycrystalline solar panels typically ranges between 25 to 30 years, depending on various factors such as quality, installation conditions, and climate. Most manufacturers offer warranties that cover the panels for 25 years, guaranteeing a certain level of performance output during their lifespan. During this period, panels may experience a gradual reduction in efficiency, often dropping around 0.5% to 1% per year.

Regular maintenance, including cleaning the surface to remove dirt and debris, can significantly enhance longevity and performance. Outdated panels may also be subject to decommissioning, which could provide opportunities for recycling and reclaiming valuable materials, contributing positively to sustainability efforts. As technology continues to advance, future panels may be expected to last even longer, leading to increased adoption of solar technologies worldwide.

HOW DO POLYCRYSTALLINE PANELS COMPARE TO MONOCRYSTALLINE PANELS?

When comparing polycrystalline and monocrystalline solar panels, a few key differences emerge. Monocrystalline panels typically offer higher efficiencies, often ranging from 18% to 25%, due to their purity; however, they also come at a higher price point. Polycrystalline panels, on the other hand, usually operate at efficiencies between 15% and 22% but are often more cost-effective.

In terms of appearance, monocrystalline panels tend to be black or dark blue and have a sleek look, while polycrystalline panels usually showcase a bluish hue with a speckled appearance. Ultimately, the choice between these two kinds of solar panels often hinges on individual needs and budgets. Homeowners or businesses with limited roof space may opt for monocrystalline for a higher output, whereas those seeking an economical solution may lean towards polycrystalline panels.

ARE POLYCRYSTALLINE SOLAR PANELS SUITABLE FOR ALL CLIMATES?

Polycrystalline solar panels can be used effectively in a variety of climatic conditions; however, their performance may vary based on environmental factors. In areas with high temperatures, polycrystalline panels might perform better than others due to a more stable efficiency in high heat conditions. However, efficiency may drop considerably during overcast or shaded situations.

Moreover, polycrystalline panels are often less responsive under extreme cold weather conditions compared to some high-efficiency alternatives. It’s essential to evaluate specific energy needs and local climate when choosing solar technology. With the right installation and maintenance, polycrystalline panels can deliver satisfactory energy solutions across varying climates.

The examination of polycrystalline solar panels reveals a profound interconnection between various components, each contributing uniquely to their function and efficiency. With silicon cells forming the core, encapsulant protecting them, backsheets offering insulation, and frames providing structural integrity, the synergy enhances performance while maintaining affordability. Assessing the polycrystalline panels’ operational mechanisms, cost-effectiveness, sustainability, and lifetime performance delivers insights for consumers looking to invest in renewable energy. The evolution of solar technology continues to inspire innovation, promising a future where solar energy can provide the bulk of global energy needs, thus paving the way towards a sustainable and environmentally responsible energy landscape. As a result, choosing polycrystalline solar panels carries significant implications for both economic savings and ecological impacts, making them a vital component of the transition to sustainable energy solutions.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-the-components-of-polycrystalline-solar-panels/