What are Solar Panel Wafer Materials?

Solar panel wafers primarily consist of 1. Silicon-based materials, 2. Thin-film technologies, 3. Advanced materials such as gallium arsenide, and 4. Emerging alternatives like organic photovoltaic cells. Silicon dominates the solar industry due to its abundance and efficiency in energy conversion, forming the backbone of traditional solar cells. Thin-film technologies allow for lighter and more flexible panels, addressing specific applications and conditions where traditional silicon wafers may not perform optimally. The ongoing research into advanced materials and innovative alternatives points toward a future with higher efficiency rates and broader applications of solar energy. For comprehensive understanding, let’s delve deeper into each of these materials, clarifying their applications, benefits, and challenges in solar energy production.

1. SILICON-BASED MATERIALS

The quintessential solar panel wafer material is silicon, which has two main forms: crystalline and amorphous. Crystalline silicon, which comprises monocrystalline and polycrystalline variants, is characterized by its structured and efficient configuration. Monocrystalline solar wafers are seen as the premium choice, boasting superior efficiency rates of about 15-22% due to their homogeneous crystal structure. Their typical dark appearance denotes higher purity levels, leading to greater energy conversion.

Polycrystalline wafers, on the other hand, are formed from multiple silicon crystals melting together. Although slightly less efficient than their monocrystalline counterparts (10-15% efficiency), they are less expensive to produce, making them attractive for large-scale installations seeking cost-effectiveness.

Amorphous silicon, another variant, lacks crystalline structure and is utilized in thin-film technology. This approach offers greater flexibility in application, making it ideal for unconventional solar installations such as building-integrated photovoltaics (BIPV) and portable solar devices.

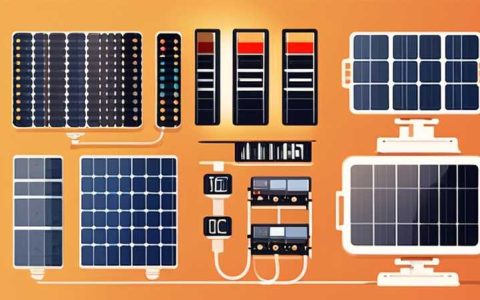

2. THIN-FILM TECHNOLOGIES

Thin-film solar technology encompasses a variety of materials, including cadmium telluride (CdTe), copper indium gallium selenide (CIGS), and silicon. While thin-film efficiency generally lags behind crystalline silicon, these materials have their unique advantages.

Cadmium telluride is among the most adopted thin-film technologies due to its effectiveness and relatively low production cost. As a result, CdTe solar panels have significantly contributed to utility-scale solar projects across the globe. CIGS thin-film cells, which combine copper, indium, gallium, and selenium, provide exceptional flexibility and lightweight characteristics. This makes CIGS panels a suitable option for rooftop installations and building-integrated applications where weight is a critical factor.

The key to the appeal of thin-film technologies lies not only in their lightweight and flexible nature but also in their ability to maintain efficiency in low-light conditions, a stark contrast to traditional silicon-based panels.

3. ADVANCED MATERIALS

Emerging technologies focusing on advanced materials are continually pushing the envelope of photovoltaic efficiency. Gallium arsenide (GaAs) is a leading contender known for its exceptional performance in converting sunlight to electricity, boasting efficiency rates exceeding 30%. This material is predominantly used in space applications because of its ability to perform well in extreme conditions and its lightweight properties.

Another promising material on the horizon is perovskite, a formation that holds immense potential for enhancing photovoltaic efficiency while reducing production costs. Perovskite solar cells have demonstrated rapid advancements in performance, achieving efficiencies over 25% in laboratory settings within just a few years of being studied. This cell type can also be produced using low-cost materials and simpler manufacturing processes, making it a strong candidate for the future of solar technologies.

4. EMERGING ALTERNATIVES

The exploration of alternative materials and techniques for solar panels continues to gain traction as sustainability concerns and technological advancements converge. Organic photovoltaic cells (OPVs) represent a noticeable shift in solar technology. These cells utilize organic materials for light absorption and energy conversion, potentially enabling low-cost, flexible energy solutions.

Dye-sensitized solar cells (DSSCs) also represent another innovative pathway with a distinct architecture that mimics the process of photosynthesis, thus offering a unique method for converting sunlight into energy. Although their efficiency levels are currently lower than conventional cells, opportunities for improvements and niche applications abound, especially in low-light and aesthetic integration scenarios.

SOLAR PANEL WAFER MATERIALS FAQs

WHAT IS THE PREFERRED MATERIAL FOR SOLAR PANELS?

Silicon remains the favored material for the majority of solar panels due to its high efficiency, including both crystalline and amorphous structures. Within the crystalline category, monocrystalline panels stand out for offering superior performance levels, while polycrystalline panels present a cost-effective alternative for large-scale operations. Emerging materials, such as perovskite, also demonstrate potential efficiency gains and lower production costs, but silicon continues to dominate the market presently.

HOW DOES THIN-FILM TECHNOLOGY WORK COMPARED TO CRYSTALLINE SILICON?

Thin-film technology involves layering one or more thin layers (or “films”) of photovoltaic material onto a substrate, allowing for significantly lighter panels. These technologies often use less material, meaning they can be produced at lower costs. Although thin-film panels typically exhibit lower efficiency rates than crystalline silicon panels, they tend to perform better in shaded conditions, can be manufactured flexibly, and are often used in applications where weight and aesthetics are critical considerations.

WHAT ARE THE ENVIRONMENTAL IMPACTS OF THE MATERIALS USED IN SOLAR PANELS?

Solar panel materials can vary widely in environmental impact. Silicon is abundant and its manufacturing process is relatively well-understood, but producing crystalline silicon requires significant energy. Thin-film materials, such as cadmium telluride, raise concerns over hazardous materials involved in their production. Many manufacturers are now working towards sustainable practices and recycling methods to mitigate any negative impacts and improve overall sustainability of the solar industry.

Solar panel wafer materials play a crucial role in the overall efficiency and cost-effectiveness of solar energy systems. As outlined above, the industry is primarily fueled by silicon-based products, including both crystalline and amorphous types, which demonstrate versatility and adaptability for various applications. The landscape does not stop there; innovations in thin-film technologies, and the advent of advanced materials such as gallium arsenide and perovskite cells, bring forth opportunities to find a balance between performance, cost, and environmental sustainability. With continued research, the emergence of alternatives could reshape the solar panel industry, affording new levels of efficiency alongside improved performance capabilities. The unyielding quest for sustainable energy solutions underscores the importance of understanding solar panel wafer materials, for a cleaner, greener future relies heavily on optimizing these technologies to meet global energy needs. As demand for renewable energy escalates, confidence in innovative methodologies will also contribute to the broader acceptance of solar energy systems across commercial and residential sectors alike. In turn, this advancement will help emphasize the overarching narrative of solar materials as critical elements in the transition towards a sustainable energy paradigm, encouraging both investment and innovation in a sector that holds immense promise for the world. Through awareness and exploration of solar panel wafer materials, individuals and industries can make informed decisions that drive sustainable change and spearhead a collective movement towards renewable and responsible energy consumption.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/what-are-solar-panel-wafer-materials/