# Comparative Performance Evaluation of YOLOv5, YOLOv8, and YOLOv11 for Solar Panel Defect Detection

Abstract

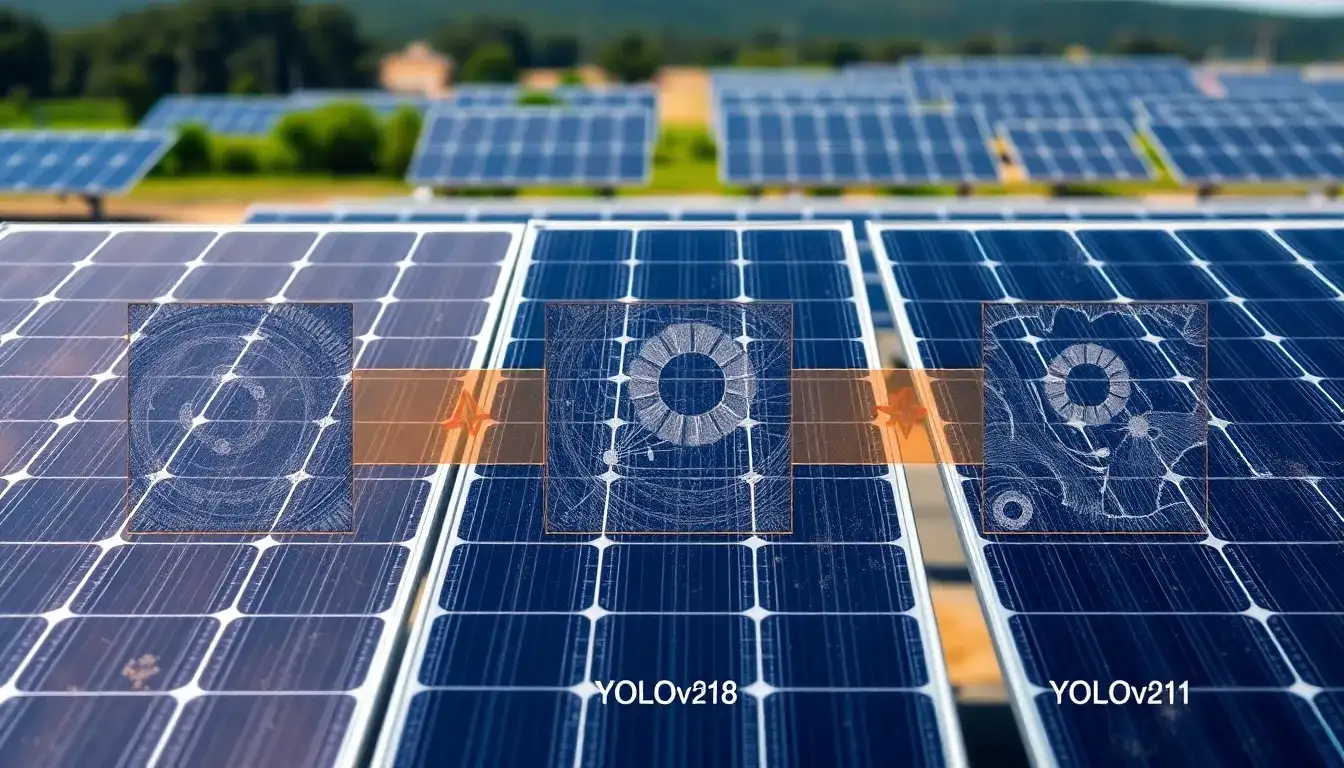

The reliable operation of photovoltaic (PV) systems is essential for sustainable energy production, yet their efficiency is often compromised by defects such as bird droppings, cracks, and dust accumulation. Automated defect detection is critical for addressing these challenges in large-scale solar farms, where manual inspections are impractical. This study evaluates three YOLO object detection models—YOLOv5, YOLOv8, and YOLOv11—on a comprehensive dataset to identify solar panel defects. YOLOv5 achieved the fastest inference time (7.1 ms per image) and high precision (94.1%) for cracked panels. YOLOv8 excelled in recall for rare defects, such as bird droppings (79.2%), while YOLOv11 delivered the highest mean average precision (mAP) of 93.4%, demonstrating balanced performance across defect categories. Despite strong performance for common defects like dusty panels (mAP > 98%), bird drop detection posed challenges due to dataset imbalances. These results highlight the trade-offs between accuracy and computational efficiency, providing actionable insights for deploying automated defect detection systems to enhance PV system reliability and scalability.

1. Introduction

The rapid adoption of photovoltaic (PV) systems as a sustainable energy solution has made their maintenance crucial for ensuring consistent and efficient energy output. Solar panels, exposed to diverse environmental conditions, are susceptible to various defects, such as bird droppings, cracks, and dust accumulation. These defects can significantly reduce energy generation efficiency and, if untreated, lead to long-term damage and increased operational costs. While manual inspection has traditionally been used to identify these defects, it is often impractical for large-scale solar farms due to its labor-intensive nature. This has created a pressing need for automated and scalable defect detection systems.

Recent advancements in computer vision and deep learning have facilitated the development of object detection models that can accurately identify and localize defects. These AI-driven approaches offer several advantages over traditional inspection methods, including higher accuracy, consistency, and the ability to process large volumes of data quickly. Among the various deep learning models, the You Only Look Once (YOLO) family of algorithms has shown remarkable potential in this domain, particularly in real-time object detection tasks, making them ideal for applications such as drone-based inspections of large solar farms.

This study evaluates the performance of three state-of-the-art YOLO models—YOLOv5, YOLOv8, and YOLOv11—for detecting solar panel defects under realistic conditions. These models were selected due to their unified development by Ultralytics, whose platform simplifies the training process significantly compared to other YOLO variants. This streamlined approach ensures a consistent implementation environment, facilitating a fair comparative analysis.

The evaluation targets a diverse range of defect types, including bird drops, cracks, and dust accumulation, while systematically assessing key performance metrics such as precision, recall, mAP, and inference time to examine the trade-offs between detection accuracy and computational efficiency.

2. Literature Review

To contextualize the contributions of this study, a review of the existing literature focuses on advancements in PV defect detection and the application of YOLO-based methodologies within this domain. Various studies have explored different YOLO versions for detecting defects in PV systems, achieving varying degrees of accuracy and efficiency.

For instance, N. Prajapati et al. identified defects using a thermal picture analysis with a CNN-based YOLO model, achieving an mAP of 83.86%. However, this study had limitations in terms of the variety of defects analyzed. In contrast, Antonio Greco et al. proposed a YOLOv3-based framework that improved precision to 92% for detecting PV panels using thermal camera footage.

Furthermore, H. Wang et al. introduced a cloud-edge collaborative approach that combined YOLOv3-tiny with transfer learning, achieving 95.5% accuracy. Other studies, such as those by A.D. Tommaso et al. and Z. Meng et al., have also demonstrated the effectiveness of YOLO models in various PV applications, emphasizing the potential of these frameworks in enhancing defect detection capabilities.

3. Background on YOLO

The YOLO object detection algorithm, introduced by Joseph Redmon et al. in 2015, transformed real-time object detection by merging region proposal and classification into a single neural network. This approach drastically reduces computation time and has evolved through various iterations, enhancing performance with each version. The timeline of YOLO development illustrates its progress from the initial release to the most recent versions, including YOLOv11.

4. Methodology

4.1. The Dataset

This study used a solar panel dataset sourced from the Roboflow Universe, comprising 6493 images annotated with four distinct classes: “bird_drop,” “cracked,” “dusty,” and “panel.” The dataset was split into training (70%), validation (20%), and testing (10%) sets to facilitate effective model training.

4.2. Model Training

The evaluation focused on three YOLO models: YOLOv5, YOLOv8, and YOLOv11. Each model underwent training on a high-performance workstation equipped with NVIDIA GeForce RTX 3060 GPUs. A standardized configuration was utilized to ensure consistency across experiments, with hyperparameters detailed for optimal model performance.

4.3. The Evaluation Metrics

Performance was evaluated using standard metrics, including precision, recall, and mAP at various IoU thresholds. Computational efficiency metrics, such as preprocessing, inference, and postprocessing times, were also analyzed to determine the feasibility of real-time applications.

5. Results and Discussions

The comparative analysis of YOLOv5, YOLOv8, and YOLOv11 for solar panel defect detection reveals comprehensive insights into the models’ performance. YOLOv5 achieved the highest precision for cracked panel detection, while YOLOv8 excelled in recall for bird drop detection. YOLOv11 provided the most balanced performance across all defect categories.

5.1. Performance Evaluation

YOLOv5 demonstrated high precision (88.4%) and recall (88.3%), indicating balanced detection capabilities. YOLOv8 showed a slight improvement in recall (89.9%) but a decrease in precision (86.9%). YOLOv11 maintained a middle ground, effectively balancing accuracy and coverage.

5.2. Detection Consistency Evaluation

YOLOv11 demonstrated the highest overall mAP of 93.4%, indicating consistent performance across classes. Class-specific mAP scores for dusty and normal panels exceeded 98%, while bird drop detection remained a challenge.

5.3. Computational Efficiency Analysis

YOLOv5 exhibited the fastest processing speed (7.1 ms per image), followed by YOLOv11 (7.7 ms per image) and YOLOv8 (15.9 ms per image). The preprocessing and postprocessing times were consistent across models, with the inference stage being the primary determinant of computational efficiency.

5.4. Comparative Analysis and Selection of the Optimal YOLO Model

While YOLOv11 proved to be the best for maximizing detection accuracy, YOLOv5 emerged as the most suitable for real-time applications. YOLOv8, with the highest recall for rare defects, is effective where minimizing false negatives is crucial.

5.5. Performance Comparison with Existing YOLO-Based Defect Detection Methods

The evaluation demonstrated significant advantages over previous YOLO methods in terms of detection accuracy and computational efficiency, highlighting the enhanced capabilities of YOLOv5, YOLOv8, and YOLOv11 for comprehensive PV defect detection.

6. Future Directions

Future advancements could include expanding the dataset, optimizing model architectures, integrating multi-sensor systems, and exploring cross-domain applications to enhance the models’ performance and applicability in real-world scenarios.

7. Conclusions

This study evaluated YOLOv5, YOLOv8, and YOLOv11 for detecting solar panel defects. YOLOv5 proved to be the most computationally efficient, while YOLOv11 offered the best overall accuracy. The findings highlight the adaptability of YOLO-based models in advancing solar panel defect detection, providing a practical solution for improving PV system maintenance workflows.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/performance-analysis-of-yolov5-yolov8-and-yolov11-in-detecting-defects-in-solar-panels/