Inductor-Based Active Balancing Topology with Wide Voltage Range Capability

With the increasing integration of batteries into the grid, the electrification of transportation, and the necessity to reuse secondary batteries for resource preservation, active balancing techniques are becoming vital for optimizing battery performance, ensuring safety, and extending their lifespan. There is a pressing need for battery management solutions that can efficiently balance battery cells across a wide range of voltage levels. This paper introduces a new inductor-based active balancing topology designed to transfer energy from battery cells to the battery pack, achieving effective balancing.

One of the key advantages of this topology is its ability to operate over a broad range of battery cell voltages. Additionally, it allows for multicell balancing with a current that is independent of the imbalance level by adjusting the width and interval of the pulses. The proposed topology can be implemented using traditional low-side gate driving integrated circuits, eliminating the need for costly isolated power modules and high-side gate drivers. The paper also presents sample balancer designs for both low-voltage and higher-voltage battery cells, with experimental results demonstrating the operation of the proposed balancer on a lithium-ion battery pack.

1. Introduction

Energy storage systems, such as batteries and supercapacitors, are utilized in various commercial and consumer applications like electric vehicles (EVs), uninterruptible power supplies (UPS), and distribution systems. Individual cells are interconnected in series and parallel configurations to meet the required voltage and power demands.

The automotive industry has seen a marked rise in the demand for lithium-ion (Li-ion) batteries, increasing from 330 GWh in 2021 to 550 GWh in 2022—a 65% increase. This surge is largely due to the growing sales of electric passenger cars, which experienced a 55% rise in new registrations in 2022 compared to 2021. However, this escalation in demand is projected to lead to the retirement of 100–200 GWh worth of batteries by 2030, as they become unsuitable for EV use, posing significant challenges due to their hazardous toxic content.

As the demand for batteries continues to grow alongside renewable energy systems and electric vehicles, there is an increasing interest in repurposing retired battery packs. Though no longer viable for their primary applications, these batteries still possess considerable capacity and energy storage capabilities, making them suitable for secondary applications such as stationary energy storage systems, off-grid solutions, and household photovoltaic units. This interest aligns with efforts to extract greater value from these assets and contribute to a more sustainable and circular economy.

Diverse types of cells are employed in energy storage systems. For instance, lithium-titanate batteries and supercapacitors are ideal for high C-rate applications in heavy vehicles and locomotives, while redox flow batteries offer a safe alternative for energy storage facilities. However, the differing electrochemical characteristics of these cells lead to varying voltage levels, rendering them incompatible with current commercial battery management integrated circuits (ICs) designed for lithium-ion cells.

Inconsistent capacity among battery cells is a primary factor contributing to imbalance, significantly affecting the overall capacity of the battery pack, as the smallest capacity cell becomes the limiting factor. As the number of charging and discharging cycles increases, the disparity in capacity can further degrade system performance. Therefore, developing a practical active balancer that can operate across a wide cell voltage range and be compatible with different electrochemical cell types is of paramount importance.

Research on active balancing methods can be categorized into three major approaches: capacitor-based, inductor-based, and transformer-based. Optimal switching capacitor-based balancers have been shown to reduce the number of switches required per cell, enhance balancing speed, and achieve multicell balancing compared to traditional adjacent cell balancing topologies. However, capacitor-based balancers face inherent limitations, including balancing speed dependence on capacitance value, the need for large capacitors, and reduced balancing current under negligible voltage variations.

Transformer-based balancing methods can be divided into isolated DC-DC converters and multi-winding transformer-based solutions. Current commercial products often use flyback converters to transfer energy from individual cells to the battery pack, but these solutions tend to be costly and heavily reliant on specific integrated circuit manufacturers. Meanwhile, inductor-based balancers present various challenges, including low efficiency in early designs and the requirement for numerous floating MOSFETs, which necessitate expensive driving circuits.

This paper proposes a novel inductor-based, low-cost balancing topology that accommodates various cell voltage ranges, provides simultaneous multicell balancing capability, controllable balancing current, and a straightforward control strategy without the need for specialized integrated circuits or controllers.

2. Proposed Balancing Topology Description

The proposed active balancing topology for an n-cell series-connected battery pack requires n pairs of switches, n inductors, n pairs of Schottky diodes, and n dual-output low-side driving ICs. The circuit’s operation is governed by a pulse signal, which synchronously activates the switch pairs during balancing. The operational principle involves two sequential steps: first, both switches are closed to facilitate energy transfer from the cell to the inductor; then, when the switches are open, the inductor maintains a consistent current flow direction and discharges energy to the battery pack.

This balancing procedure operates independently for each cell, allowing multiple cells to discharge simultaneously. The topology functions without regard to cell voltage level, so long as the cell can charge the inductor and its voltage does not drop below the minimum operating threshold.

3. Control Signal Generation and Efficiency Analysis

This section delineates the generation of PWM control signals and analyzes energy transfer efficiency to assist in selecting suitable operating parameters for implementing the proposed balancing topology. The efficiency calculations do not account for eddy current losses or energy consumed by the driving circuit.

4. Experimental Setup and Test Results

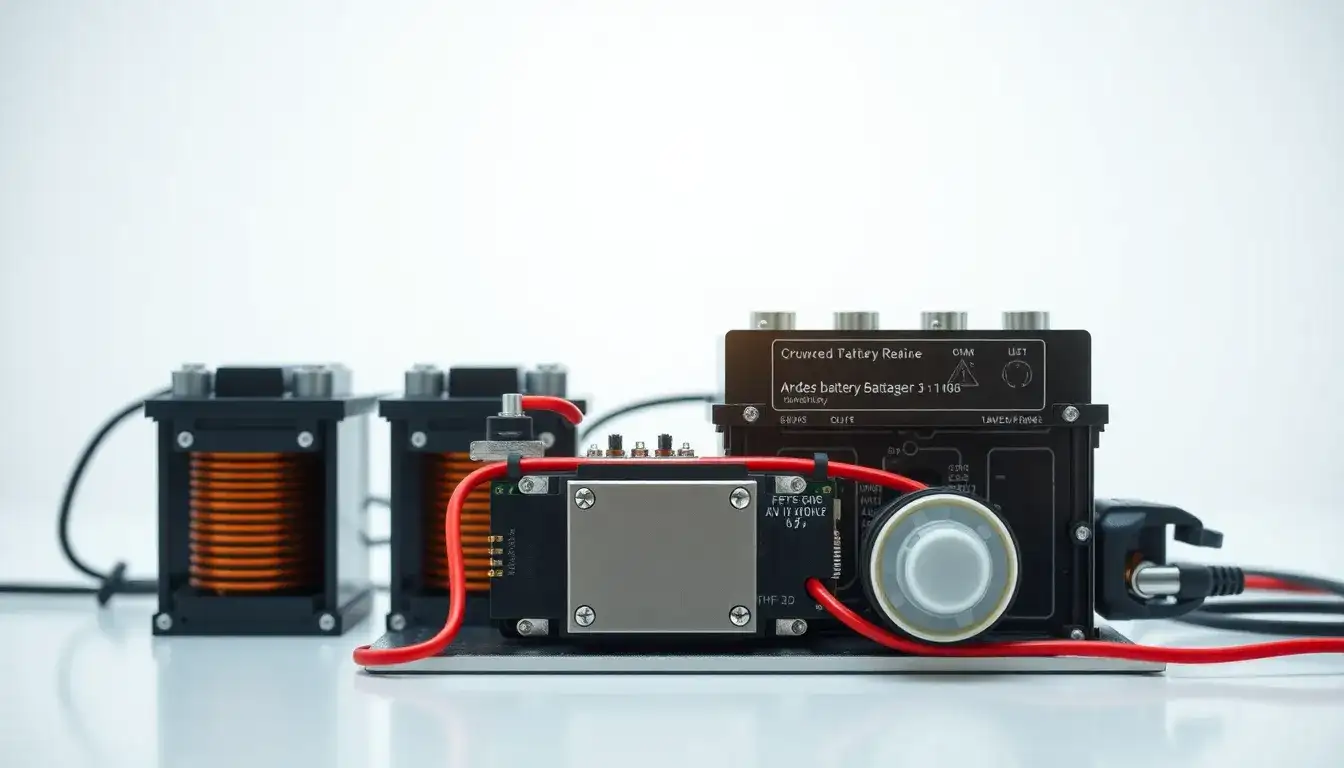

To validate the proposed balancing topology and its cost-effective driving circuit, a series of experiments were conducted. The experimental setup involved a five-cell series-connected battery pack, a balancer board with the gate driving circuit, and a controller for voltage measurement and data logging. The experimental results demonstrated the effectiveness of the balancing algorithm, showing the convergence of cell voltages during both charging and discharging operations.

5. Conclusions

This paper reviewed existing solutions for active balancing and proposed a novel, inductor-based active balancing topology capable of functioning over a wide range of cell voltages. This topology integrates the necessary driving circuits, thereby reducing overall system costs while maintaining a simpler control structure. The proposed system efficiently transfers energy from individual cells to the battery pack, enabling multicell balancing with a balancing current unaffected by the level of imbalance, supported by a straightforward control algorithm. Future work will focus on adapting the circuit design for series-connected pack-level balancing and will include validation on larger battery modules and real-world applications.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/inductor-based-active-balancing-system-for-enhanced-battery-management-across-wide-voltage-ranges/