To successfully remove a solar pipe, adhere to several essential steps. 1. Prepare the required tools and materials, 2. Assess the surrounding area and ensure safety, 3. Carefully loosen the connections, 4. Detach the pipe without damaging adjacent components. The most crucial point is the preparation of tools, which typically include a wrench, screwdrivers, and, occasionally, lubricant or penetrating oil.

PREPARATION

Preparation is fundamental when approaching the task of unscrewing a solar pipe. Identifying the necessary tools is the first step. Generally, one may need adjustable wrenches or specific socket sets to fit the connections properly. Sparse environments can necessitate a comprehensive review of the components involved, ensuring that all fittings are accessible.

Additionally, safeguarding the worksite is equally important. Wearing safety gear is recommended, including gloves and goggles, to prevent any injuries from unexpected occurrences, such as falling debris or sharp edges. Furthermore, inspecting the system for any residual pressure or danger is vital. Solar panels operate under a specific pressure, and any recklessness could lead to unfortunate accidents. Once safety is ensured, one can confidently proceed to the next step.

LOOSENING CONNECTIONS

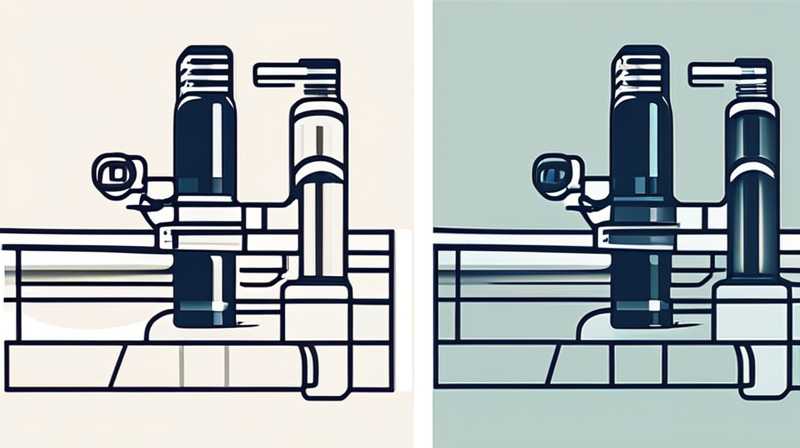

With a secure setup, attention must shift toward the connections that bind the solar pipe to the rest of the system. Careful examination of the fittings is essential to fully comprehend how they are secured. Rust, dirt, or other forms of degradation may have inadvertently created a stronger bond than intended. In such cases, using a penetrating oil may facilitate the loosening process. Applying an ample amount of oil can help dissolve grime that restricts movement.

Once the oil has had sufficient time to work, utilizing the proper tools comes into play. Selecting a wrench that fits snugly around the connection prevents slipping and potential damage to the pipe itself. Grasping the connection firmly and applying gradual pressure ensures that the components do not break apart unexpectedly. If any resistance is felt, it may signify that more lubricant is necessary before proceeding.

REMOVAL TECHNIQUES

When sufficiently loosened, the technique for detaching the solar pipe becomes paramount. Two primary approaches exist: rotational turning and pulling. Typically, a straightforward turning motion will work for most screws. However, if the pipe does not yield, a gentle but firm pull may be necessary. One must ensure that their grip does not damage the adjacent components.

While utilizing these methods, it is crucial to maintain control and stability. Overzealous pulling or pushing can lead to damage beyond the target area, resulting in costly repairs or complications in the future. Alternating movements from turning to pulling cautiously may yield better results than attempting a one-size-fits-all strategy.

FINAL CLEANUP AND MAINTENANCE

Once the solar pipe has been successfully unscrewed, completing the process involves thoroughly inspecting the area. First, evaluate the condition of the pipe itself. Signs of damage or wear may necessitate repairs before reinstallation. Next, be vigilant in verifying all other components remain intact and functional, ensuring future efficiency of the system.

Cleaning the area around the pipe is also advisable. Debris or leftover residue can compromise the binding between components in reassembly. Taking a few extra moments to tidy up can result in a smoother workflow when reinstalling the solar pipe or making any required repairs. Once all inspections and cleanups are done, one can confidently proceed to either install a new pipe or reattach the existing one.

COMMON ISSUES DURING REMOVAL

Even after preparing adequately and following steps, some common issues may present themselves while attempting to unscrew a solar pipe. Corrosion within fittings is a frequent complication, leading to difficulties in loosening connections. Implementing various solutions, including chemical rust removers, may alleviate such problems.

Another obstacle may arise from overly tight screws or bolts, posing significant challenges to both amateur and experienced individuals. If all else fails, enlisting the help of professionals may be a prudent option to prevent potential damage.

FAQS

WHAT TOOLS DO I NEED TO UNSCREW A SOLAR PIPE?

To effectively unscrew a solar pipe, various tools are required to ensure successful removal. Wrenches, especially adjustable and socket types are crucial for loosening the connections that bind the pipe to the solar system. In addition, a set of screwdrivers, including both Phillips and flat-head types, may be needed to tackle different screw heads that can appear in connection points.

Using penetrating oil or lubricant is also recommended, as it assists in loosening rusted or stubborn connections. Gloves and safety goggles provide personal protection and mitigate the risk of injury. A steady flashlight could enhance visibility, especially if working in tight, obscure spaces. Ultimately, assembling these tools beforehand reinforces the likelihood of performing the task efficiently and safely.

HOW CAN I SAFELY HANDLE SOLAR SYSTEM COMPONENTS?

Handling solar system components with safety in mind is vital. Always start by wearing protective gear, including gloves and eye protection. This ensures that any sharp edges or unpredictable occurrences do not result in injury. Before commencing work, evaluate the entire setup, checking for leaks or pressure that may pose hazards.

Working in a well-ventilated area is highly recommended, particularly since some components may contain residual pressure or chemicals. Additionally, using proper lifting techniques when moving components minimizes the risk of injury. When requiring additional aid, don’t hesitate to enlist assistance from others who may provide an extra set of hands. Following these safety measures guarantees an effective and secure working environment.

WHAT ARE SIGNS THAT A SOLAR PIPE NEEDS REMOVAL?

Recognizing when a solar pipe requires removal can prevent further complications down the line. Visible signs of wear, such as cracks, rust, or leaking, warrant immediate attention. If water is leaking from the connections or along the pipe itself, swift action is necessary to avoid extensive damage to the solar system.

Another indicator may be inefficiency in solar energy conversion, where diminished output is noticeable. If routine inspections reveal sediment buildup or scaling within the pipe, it is likely time for removal and servicing. Lastly, unusual noises or vibrations during operation may suggest that the integrity of the pipe has been compromised. Addressing these signs proactively eliminates the risk of larger systemic issues.

BOLD CLOSURE

Successfully removing a solar pipe is a multi-step process that necessitates preparation, attention to detail, and often a good understanding of mechanical principles. By ensuring all necessary tools are at hand and prioritizing safety from the onset, one can efficiently navigate the complexities involved. The thorough inspection of connections and careful application of lubricants to loosen tight components is critical in preventing damage. Adapting removal techniques as needed, while remaining vigilant about potential issues such as corrosion and excessive tightness, establishes a solid approach. After detaching the pipe, performing a meticulous cleanup and inspection guarantees that subsequent installations are executed seamlessly. Awareness of the indicators that signal a need for pipe removal can further enhance the integrity and efficiency of the solar system. All these points collectively underscore the importance of a systematic, methodical approach to this task.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-unscrew-the-solar-pipe/